|

Re: Continuing on the Overdrive

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Glad things looking up. As long as the hold coil is keeping the plunger out, lower voltage is not an issue at term 3 as you are taking the reading at a point somewhere toward the midpoint of two coils in series.

The relay contact should not be closed with it out of the car so there is either something sticky holding, a bind of some type, the spring is weak, or some residual magnetism in the core which may be a stretch. Checking one I have, it snaps right out. There are ways to demagnetize if that is reason but not sure of best approach in this case--relay cores don't normally magnetize. Maybe Bob1951 would have some ideas. Check the other causes and then would try in car first and see if once in motion it causes a problem. It may bounce open with movement which would be great. If it does not & continues to stick would be an issue only if solenoid binds or for some reason prevents that ground out or kill contact inside to not open. Then it would cause engine to stall if it stays closed.

Posted on: 2009/8/28 10:58

|

|||

|

||||

|

Re: Stuck in reverse

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Just wondering what you are calling second? In the left triangle should be one "shift" which is not really a shift in sense of changing gears but just going into direct drive locking out the converter. In the right triangle should be one actual shift from low to high and then the direct drive. The direct drive can groan or buzz when engaging but don't remember it as harsh. Here is a tech bulletin with approx speeds all this should happen.https://www.packardinfo.com/xoops/html/downloads/STB/55T-6.pdf Has the throttle linkage adjustment been checked? That pretty much determines when and how hard shifts are.

Posted on: 2009/8/27 21:30

|

|||

|

||||

|

Re: Gear selection window

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Morgan, glad your car is now able to tell you what gear it's in. Did you get your transmission problems sorted out?

Posted on: 2009/8/27 21:10

|

|||

|

||||

|

Re: Continuing on the Overdrive

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Clipper 47. Thanks and glad it was understandable.

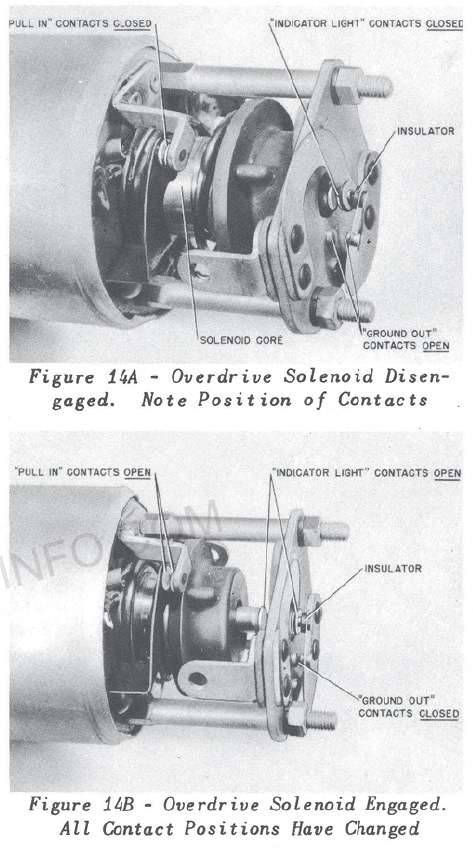

The operation of the light is supposed to be as soon as speed is reached and OD is possible it illuminates and stays illuminated until you are in OD and the solenoid has fully engaged. There are a set of contacts in solenoid that then open and light goes out. If you kickdown out of OD but are still above speed, light will go on again as contacts close to tell you that it is still possible to go into OD. If yours is not doing that then probably the contacts have worn out of adjustment or the wire to solenoid terminal 7 is shorted somewhere. The contact adjustment is a PIA. Out of curiosity looked at 2 solenoids and one opens at about 1/8 from end and on other it has to be all the way out. Here is a pict of contacts in both states.

Posted on: 2009/8/27 20:39

|

|||

|

||||

|

Re: Continuing on the Overdrive

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Relay should not be grounded and is mounted on vibration pads so everything should be at least 3/8 inch away from metal. Sounds as if relay is working at least. The continuity question depends on how things were connected when you made the test so can't hazard a guess but if solenoid totally disconnected and out then that pretty much leads to wiring or motion as you mention. This is a bottom and side shot of the relay so you can tell if yours might be too close to firewall.

Posted on: 2009/8/27 19:32

|

|||

|

||||

|

Re: Continuing on the Overdrive

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

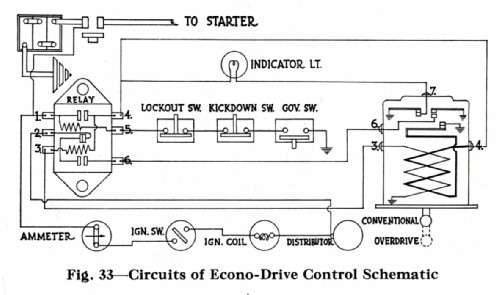

Here is a bit more to add to the mix.

R9 Relay operation: There is a bit of description in the manual but maybe this will flesh it out--or confuse issues further. Power is supplied to terminal 1, thru first relay coil & out terminal 5. Thru closed lockout switch, closed kickdown switch and gets ground when car reaches speed. First relay energizes and provides power to term 4, solenoid pull in coil and indicator light. Indicator will light as solenoid still not fully engaged and light contacts are closed. At the same time first relay opens the contacts tied to terminal 2. Power is also supplied to and thru the coil of second relay and out terminal 3 to hold coil. Since they are in series, second relay closes contacts tied to terminal 6 and hold coil now has power and will prevent the machine gunning. When you let off the gas, engine torque is released, and solenoid fully engages. Pull in coil contacts open that circuit. Indicator light contacts open, extinguishing light, but engine kill contacts now close at 6. Engine is not affected though because kill circuit goes thru term 6, closed second relay contacts but no further because first relay contacts are now open so can't exit on term 2 and get to distributor. This is the state of things as long as you are in overdrive. When you exit overdrive via kickdown, that switch opens dropping out first relay and power to solenoid. Solenoid can't release until torque released so kill circuit is now completed by previously open first relay contacts at 2 and engine skips a beat until solenoid drops out and opens that set of kill contacts. Just before it opens the kill contacts it closes pull in coil contacts. The second relay will drop out because it also lost power but because it's coil is now in series with pull in coil & hold coil, will have a slight delay of a few milliseconds until everything quiets down. There is a bit of a race as to which contacts opens first but once open it ensures kill circuit is open in case of a bind at solenoid and engine can continue running. When OD is in lockout, nothing can be energized when governor reaches speed because ground never reaches relay.

Posted on: 2009/8/27 14:33

|

|||

|

||||

|

Re: Continuing on the Overdrive

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Lets make sure we're talking of same type relay for starts. Here is R9 relay and pict with cover removed and terminals identified. Term 1 is fed directly from battery via starter solenoid post so does not go thru ignition switch. As to why solenoid would energize after touching with your light, if governor grounded and switches & relay functioning properly, term 3 & 4 and solenoid should have already been energized so just lit the test lamp--don't understand the on/off unless there is a bad connection when you push on it.

You can ground terminal 5 directly-just won't have all the circuitry to rule anything out but if you have determined both switches and wires good, then easier than crawling under. When you refer to a kill switch--is that just a battery disconnect in cable from battery? Also, looking at the 41 general schematic it appears yours does use the black connectors and the short loom so worth a look there.

Posted on: 2009/8/27 13:13

|

|||

|

||||

|

Re: Continuing on the Overdrive

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

The EC has a separate fuse so other than also getting ground at the governor, it is totally independent.

With machine gunning, it's possible the #3 wire is bad or also possible there is a problem in relay. Since solenoid worked properly with 3 & 4 connected on bench, that tends to lead that way. The 20 amp fuse wouldn't have caused it--just blown when it was doing it. There was a modification in late 40's to add a safety switch to open the hot wire when in reverse. It may have also been done to your car so that would be a good thing to check. Terminal 1 of the relay should have power at all times if no switch was added and at all times except when in reverse if it was. Using your test light with one side to ground, check that terminal and see if power present--If later switch used, it was operated by reverse lever so also wiggle the gearshift when checking other gears & make sure not mis-adjusted. If that is OK, then if the governor is grounded you should also have a light at terminal 4 and 3. If so, relay is good and would try the external wires. Just use some wire approx the size of the ones in loom and make sure if solenoid not mounted, that is has a good solid ground of at least same size wire bolted to mounting hole and frame ground. If power is at 1 but not 3 & 4 with governor grounded, then need to check the wiring and the lockout, & kickdown switches coming into terminal 5. An added note: I don't know the particulars of your loom but just remembered there was also a bulletin in later years about the overdrive harness. The black connectors where a short loom containing the 6 wires from governor and solenoid joined the main loom having poor connections was the issue. If your loom is 2 piece constructed the same way with those connectors, might be worth a look.

Posted on: 2009/8/26 11:30

|

|||

|

||||

|

Re: Continuing on the Overdrive

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

The only reference I'm aware of is the Econodrive training manualhttps://www.packardinfo.com/xoops/html/downloads/EconoDriveTrainingBook.pdf which you probably have. The section on electrical operation gives a breakdown of what each component does but nothing on point to point like the electromatic book gave you. There may be a service letter with a few snippets but nothing really detailed.

Part of the problem with checking electrical point to point is the car has to be in motion to see if OD actually works. When sitting, you can ground the governor and listen for solenoid and then push accelerator or move the lockout lever to see if it releases, but that's about it. Even that might not help because if OD is not in a mechanical position to accept full travel of solenoid pawl, any further checks that relied on full engagement might not be valid. It is also not a good idea to keep R9 solenoid sitting part way with pull in winding energized for a long period that the tests might take because of the possibility of overheating it.

Posted on: 2009/8/25 22:46

|

|||

|

||||

(51.01 KB)

(51.01 KB)