|

Re: 12 Volt Relays in a 6 Volt System

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Relays should work for your situation but am wondering about the cost. From what I can see with a quick check, average for 6v relay is around $20-25 each. Rusty's suggestion in any case, would be a good start.

Am wondering about the possibility of this itemhttp://automotive-hardware.com/universal-turn-signal-switch-black-p-307.html working. The schematic looks to be very similar to what the relays will accomplish but of course, the devil is in the details inside the switch. There is another company that advertises a more or less custom fixhttp://www.turnsignalsforclassics.com/ which also sounds as if it might fit your situation. Another seems to be similar to the firsthttp://www.dealparts.com/product/16-2101-0.html but may not have the stoplight function. Anyway, just a few more options to confuse you further.

Posted on: 2009/8/4 9:43

|

|||

|

||||

|

Re: 48-50 Fuel Sending Unit Question

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

48 is bimetal & not a typical later resistance unit so readings will be all over. There is a discussion herehttps://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=29603#forumpost29603. I was measuring around 13 ohms on a NOS unit until I assume the contacts changed with the float action and it jumped high.

Assuming the heater element is intact on each end, wiring good and contacts & ground clean there doesn't appear much to repair. About the only moving part is the cam action which flexes the bimetal so it takes longer for heater to open contacts when tank is full. If that is happening, gauge heater should also be on longer and needle should move further. After this info was posted, someone went and tried a Ford unit as mentioned in the thread. I believe it was for a 30 something on -maybe 37-8-9 and gave the place purchased which was a Ford antique auto place. For the life of me, can't find the thread now but he reported back & said it worked. If you have better luck with search, maybe you can find it if you decide to replace -- wasn't that long ago.

Posted on: 2009/8/3 11:19

|

|||

|

||||

|

Re: 12 Volt Relays in a 6 Volt System

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Although generally the answer is no, they won't work --it all depends on the minimum pull in voltage and current requirements of the particular relay and some might under the right circumstances.

If you want to go the relay route, here is info on 6 v relays.https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?post_id=28404#forumpost28404

Posted on: 2009/8/3 7:42

|

|||

|

||||

|

Re: Since Packard had a V-12 in the 30's....

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Quote:

Perhaps Packard tried a cast or forged slug design aluminum piston, good poor results, and changed to cast iron while they quickly sourced an improved design?

Posted on: 2009/8/2 19:15

|

|||

|

||||

|

Re: Since Packard had a V-12 in the 30's....

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

The only reference I was going by was posted above and speculating as to the reasons.

Quote: Well, here's what I found on the aluminum vs cast iron history: ""Pistons [on the '23 model] were slotted aluminum alloy but reversion to cast iron (as in the Single Six) was made in December when aluminum was found to suffer from warpage, piston slap and wear." Packard, A History of the Motor Car and the Company, Beverly Rae Kimes, ed., copyright 1978, Automobile Quarterly, Inc. p. 238.

Posted on: 2009/8/2 18:48

|

|||

|

||||

|

Re: Since Packard had a V-12 in the 30's....

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

If they were autothermic back then and still suffered from warpage, piston slap and wear, then if not casting & foundry it would almost have to be a different design or better alloy.

Posted on: 2009/8/2 18:41

|

|||

|

||||

|

Re: Manual control of torsion-level system,

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

If either limit switch failed, it would be a large problem-yes. On several damaged units I've seen, it seems the deed is done and splines sheared before the fuse even thinks about blowing.

Posted on: 2009/8/2 18:26

|

|||

|

||||

|

Re: Manual control of torsion-level system,

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

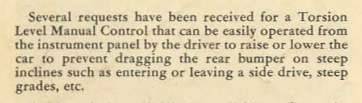

Pros are from the official Packard reasoning plus makes changing a rear tire easier--and it's also a neat wow feature at the local cruise. Cons would be negligible if the level system is in proper order & you didn't wear something out or drain the battery showing it off.

Attach file:  (7.62 KB) (7.62 KB)

Posted on: 2009/8/2 17:53

|

|||

|

||||

|

Re: Since Packard had a V-12 in the 30's....

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Quote:

Don't know when they resumed aluminum, or what changes allowed them to,

Posted on: 2009/8/2 17:48

|

|||

|

||||