|

Re: Drifting air fuel adjustment

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Wonder if a couple of external tooth star or serrated lockwashers would provide enough grab to keep vibration under control. One at the carb between spring and base and the other at the screw head might bite into the spring and each surface to hold it in position. If that would not work perhaps a small dab of gas resistant glyptal or varnish at the threads would seep in just enough to lock it down but would still "crack" open to allow future adjustment.

Posted on: 7/11 14:14

|

|||

|

Howard

|

||||

|

||||

|

Re: PAC site question

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

HPH, An excellent question and one that puzzled me when I first ran into it. After reading their Newsletter notice you posted here I reluctantly agreed with the reasoning for the other categories they limited but not the forum. Seems to me like they would want to have an information outlet wide open but apparently not. Maybe it has something to do with spam posts which had gotten somewhat prevalent there.

After the initial limit to the forum something happened and it was open again for a couple of weeks or so. Whether that was an accident, a trial run, or something else is unknown but it was locked down tight again and has stayed that way since. It is a shame that some people will not get a timely answer or maybe any at all as you are correct in that the traffic there has been very low for some time. Many do not know about packardinfo to ask questions here either. AACA used to be the go to forum for Packards but I think it was some actions by a heavy moderator that drove people away from there so it also is barely alive. Kev stepped in to start this forum so we can thank him for packardinfo being open and so popular. Between a former moderator at the PAC forum and the lockdown I fear the same has or will happen to that forum. Whether people are going to a facebook place I suppose that is a possibility but I am not now or ever will be a member of facebook and I expect there are many others who feel the same way.

Posted on: 7/11 13:51

|

|||

|

Howard

|

||||

|

||||

|

Re: WTB: 1939-40 160 Coupe Super 8

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Joe Block had a prewar unit for sale last year but no idea if he still has it. Perhaps someone else has his contact info as I don't believe he checks in at this forum very often.

As far as modern compressors, unless you are into fabrication or find an older rebuildable York orTecumseh compressor which, while still wrong, would look more appropriate I believe you will be limited to one or two models of the Sanden unit. Universal mounts are easy to find and modify for the Sandens but you will still need to fabricate your own bracket. I think the simple design Ross came up with is one of the better and easier to make for the Sandens. In addition, there is no provision on the crank pulley to drive the compressor as Packard chose to drive the prewar compressors via a special fan pulley. You will need to figure out how that is best done and depending on how the engine sits, there may be no clearance room at the crossmember to add an extra groove to the vibration damper. Some have used one long belt to drive the fan, generator, and compressor pulleys but those were on postwar cars. I don't know if that will be feasible depending on which engine you use. Some of the engines have fairly wide belts but I don't know if whip would be an issue with heavy belts and long unsupported lengths between pulleys. There are a few Sanden compressors working on 6v. Specs say they need 7+ volts minimum to pull in and if the generator is operating properly it seems to work. Dwight Heinmuller is running his 54 factory air car that way but don't know who has the other units or what type they are.

Posted on: 7/11 13:04

|

|||

|

Howard

|

||||

|

||||

|

Re: 282, 288, 327, 356

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Quote:

You can mill .060 off the 282 head with no probs. Don't know what CR that will give you. But as with the later heads suspect that would be only if the head had not been milled before. I don't know if there have been any thickness comparisons made on the 282 heads such as Ross did for the later heads but expect blindly milling a 282 head with an unknown history would have the same perils as the later item. Many a later head has been milled with best intentions and then put back on an engine only to find too much was removed and valves were now hitting the head. Some newly rebuilt engines had major valve damage quickly develop because clearance on a newly milled head was not checked before bolting the head down.

Posted on: 7/11 9:13

|

|||

|

Howard

|

||||

|

||||

|

Re: 282, 288, 327, 356

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Here is a chart showing the different ratios that can be obtained by swapping heads between the later engines. As far as I know the later heads will not fit the 282 block so any simple ratio change on that engine might not be possible. Others will correct me if I am wrong and the heads do fit.

Posted on: 7/10 22:39

|

|||

|

Howard

|

||||

|

||||

|

Re: 282, 288, 327, 356

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Here is the factory info on swapping a 39 320 engine with a 5 main 1948 327 which would be identical in size to the 288 engine. While the 282 is not the same size engine as a 320 I suspect the major points to the install as far as body and frame changes will be very similar between the two engines. There are some other articles in the Service Index on changing engines. In the 35-37 junior category is one regarding installing a later engine in a 120 and another article in the 41-7 section on installing the newer engine in a prewar RHD car also mentions body changes that are needed. An article in the 48-50 section covers replacing a 356 with the 327 which might also provide some info.

Blocks made for 51 and later production had motor mounts on the side rather than in the front so the old front mount items from the 282 would need to be reused and possibly they or the block might need to be modified to bolt the mount onto the newer block. Some holes used for accessory or transmission linkage attachment on the side of the block in some pre 51 models are also missing on the later blocks. There are other bolt on items that might also need to be reused or modified.

Posted on: 7/10 22:03

|

|||

|

Howard

|

||||

|

||||

|

Re: Polarizing generator

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Quote:

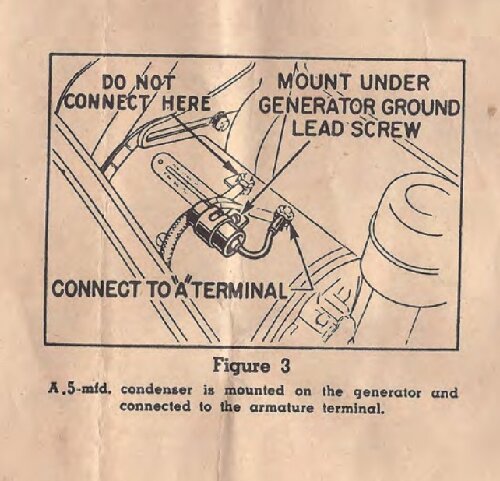

What do I do with the ground wire now? If it is the factory ground wire that is going to the fender terminal strip, the generator end should be connected to the same screw the condenser body is using for its mount. That screw is pointed out in the radio condenser instructions in post #19. If your generator is a bit different than the diagram, the ground point is typically a screw that will be threaded directly into the generator body and will not have any insulating washers or other material surrounding it. There should only be 3 wires and the condenser connected to the generator. Any other wires would not be stock and would need to be chased to find where going.

Posted on: 7/10 14:55

|

|||

|

Howard

|

||||

|

||||

|

Re: Polarizing generator

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

It is possible some oil got inside the generator and on the commutator and is causing issues if it got inside one of the end openings. If you have a brush cover over the end it should prevent the majority of oil from entering and the bit that did get inside would probably not cause too many problems. It would not hurt to check though if there is a cover that is removable.

The capacitor is for radio interference and as HPH said, should be connected between ground and the ARM terminal to minimize noise and whine caused by the brushes sparking.

Posted on: 7/10 12:34

|

|||

|

Howard

|

||||

|

||||

|

Re: Polarizing generator

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

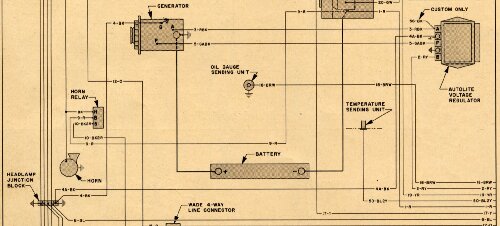

With stock generator wiring, there should have been a thick 10 ga wire on the ARM terminal going to regulator and a smaller wire on the FIELD terminal also going to regulator. An extra ground wire should not be needed because a separate ground wire goes from the screw threaded directly into the generator case to one of the mounting screws at the Left front fender headlight terminal block. Another wire also connects to the terminal block mounting screw and carries the ground on to the regulator.

Some regulators have a ground screw where the wire connects, others just use one of the regulator mounting screws as the connection point. That ground is for reference to ensure the regulator and generator are seeing and working with the same voltage and no voltage drop is the result of bad connections between the block, linkage, or sheet metal pieces. It should not carry much current other than perhaps a minimal amount for the field coils. The generator mounting bolts and bracket to the block are what carries the high output current from the generator to the battery ground cable to supply the car and battery.

Posted on: 7/10 10:53

|

|||

|

Howard

|

||||

|

||||