|

Re: 359 Noisy Lifters

|

||||

|---|---|---|---|---|

|

Not too shy to talk

|

As for the cylinder head, customer directed to use the 327 head from his 53 Caribbean which the 359 is going in

Posted on: 2023/7/3 16:35

|

|||

|

||||

|

Re: 359 Noisy Lifters

|

||||

|---|---|---|---|---|

|

Not too shy to talk

|

Howard/Kev;

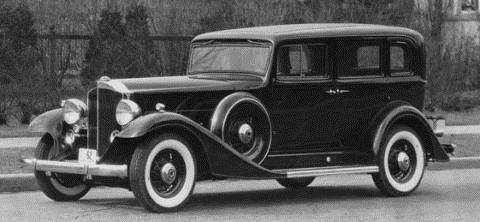

I think we might be on to something. In the attached photo, the four way fighting on the left is what was on the engine and both sides are restricted to 5/64" (#47 bit) (filter side and feed to the lifter valley) and four way on the right is one I pulled from my stash and it too is restricted on both sides. Interesting, hmmm. I'm wondering if we should open the restriction to the valley feed based on your comments. Regards, Eric

Posted on: 2023/7/3 15:27

|

|||

|

||||

|

Re: 359 Noisy Lifters

|

||||

|---|---|---|---|---|

|

Not too shy to talk

|

ALCON;

All good info. Engine was first started with break-in oil, then drained and refilled. Earlier this morning, drained out the molasses and filled with 10/30W. Engine has been running now for thirty plus minutes and still noisy. I'm still suspect on wrong lifter plungers as I have no clue where they came from nor, a part number. I was provided with the parts. The oil pressure readings are taken from the rear main plug on the right rear and from the main supply (gauge in cluster - top is the main feed).

Posted on: 2023/7/3 11:55

|

|||

|

||||

|

Re: 359 Noisy Lifters

|

||||

|---|---|---|---|---|

|

Not too shy to talk

|

I've got to double check my notes on the clearances of the valves, I'm suspecting faulty lifters.

I might take you up on the tool - will call speedwell tomorrow morning and let you know. Howard, you might be on to something, I did look at the old donor block and the plug does have the hole mentioned in the bulletin at 12 o'clock position. I might drill the hole in the pipe plug as well Thank you.

Posted on: 2023/7/2 13:53

|

|||

|

||||

|

359 Noisy Lifters

|

||||

|---|---|---|---|---|

|

Not too shy to talk

|

We rebuilt this engine, camshaft reground and tappets were surfaced as well - we were provided with what appeared to be NOS plunger assemblies (no part number) to be used for the build.

After priming the engine we got 30 psi with a drill fixture. We then finished the assembly on our run stand and fired up, at this point we noticed the lifters to be EXTREMELY noisy so we shut it down and began investigating and found a plug in the front lifter galley wasn't installed correctly so we corrected that by taping a pipe plug into it. Pressurized the system directly to valley and saw oil coming out of the bleed holes and buttoned it up. Ran it yesterday and after initial startup they were quiet however as the engine ran and warmed up they continued to get noisy again. I know the 50-54 uses a different part number than the 40-48 so what's difference? Is it possible the 40-48 are different just enough to allow excessive bleed and that's what we installed? I have the original plungers soaking now. Oil is 20/50 Classic Lucas with zinc as well. The engine runs great and really smooth. Any thoughts? Eric

Posted on: 2023/7/2 8:10

|

|||

|

||||

710108329.jpg (338.14 KB)

710108329.jpg (338.14 KB)