|

Re: Compression readings

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

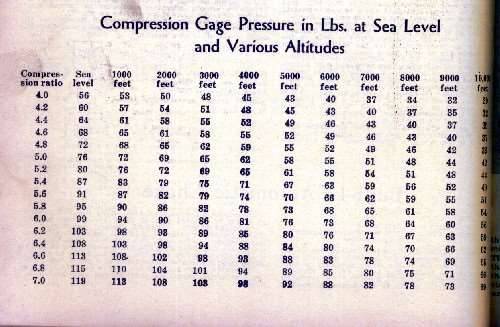

The factory spec for compression was usually in the issue of the Service Letter containing the full specifications, but when in doubt or if you don't have that you can always refer to this.

Your values seem quite acceptable to me and I wouldn't expect that car to burn oil because of rings. If your visible smoke is just after coasting down a hill and then accelerating, it's most probably the valve guides that are causing it, not the rings.

Posted on: 2012/6/30 16:32

|

|||

|

||||

|

Re: Compression readings

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks, Owen.

According to the chart, here at sea level I should expect 119, so I guess I'm not too far off with this 64 year old. I was thinking guides and seals too, but I'm not sure if the symptoms are the same with a flathead as they are with an OHV engine. An OHV will pull oil through the guides at idle, as the vacuum is high but also gravity is at play. On a flathead, with the oil having to migrate up instead, is it as much a factor? The symptom of bad guide seals is usually smoke upon acceleration after idling, as the oil pulled in at high vacuum burns away, and smoke when accelerating after coasting, when the throttle was also closed creating a high vacuum situation. I'm totally baffled as to how to do a valve job on a flathead. Is it commonly done with the engine in the car? How do you grind the seats? Especially near the firewall. It must be difficult to install valve spring keepers upside down. But if it's less complicated/expensive than pistons and rings, I'm all for it.

Posted on: 2012/6/30 17:03

|

|||

|

Joey

(?=#=?) "If chrome got me home, I'd for sure still be stuck somewhere." [url=http://pac |

||||

|

||||

|

Re: Compression readings

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Your compression reading don't really indicate any significant problems with valves (guides being another issue). Have you checked your manifold vacuum at idle - this is another good diagnostic for valve condition?

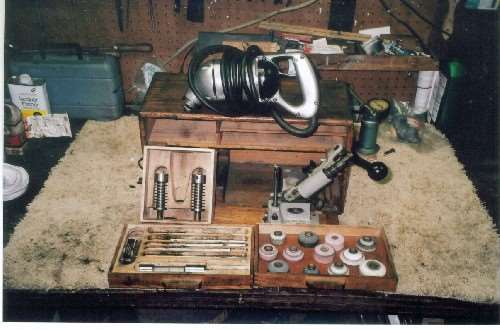

These flathead engines do not use seals on the valve stems. And yes, valve jobs are typically done with the engine in the car unless the engine is to be removed for other reasons. No problem installing the keepers, though there is a special tool made for it I generally don't use it, I just put a dab of grease on each one to hold it in place while I lower the spring and retainer. If you need to grind the seats, you can use a grinder kit like mine, and have the valves themselves faced by any decent automotive machine shop. Watch the seat and face angles, they are different intake and exhaust on most Packard in-line engines. You'll also need a valve spring compressor and some drifts if you're going to change any guides. If you have hydraulic lifters you'll also need a gauge to set the min and max clearance of the stem to the lifter. All these tools are pretty common. If and when you decide to do a valve job, send me a PM, I've done far more than I'd care to count on Packards L-heads and would be glad to help with the details. Perhaps this will help you get starting thinking about the valve job. packardclub.org/forum/viewtopic.php?f=14&t=862

Posted on: 2012/6/30 17:23

|

|||

|

||||

(122.32 KB)

(122.32 KB)