|

Re: ANOTHER #%*!:( BTV failure

|

||||

|---|---|---|---|---|

|

Home away from home

|

First things first:

Check the brake fluid level in the BTV reservoir. If the brake fluid level is more than 1/4 low then pay close attention to the vacuum power unit when it is removed. Pour out any brake fluid that mite be in the vacuum power unit and measure the amount please (+or- 2 oz.s accurate enuf).

Posted on: 2010/10/3 17:00

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: ANOTHER #%*!:( BTV failure

|

||||

|---|---|---|---|---|

|

Home away from home

|

Eric,

Thanks for the reply and for being back on here for a go to source. It will probably several weeks before I can tear into car but when I do I will pm you for number. Thanks again for sharing your experience and knowledge.

Posted on: 2010/10/3 20:17

|

|||

|

||||

|

Re: ANOTHER #%*!:( BTV failure

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

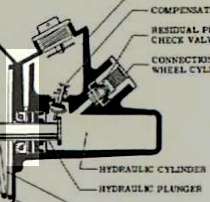

KevinAZ, what are you calling the check valve pathway? There is only the one residual check valve at the end of cylinder where it exits to the brake line.

Where I believe the problem lies in most cases is in the compensator valve. That one blob of rubber and the seal around the assemby is the only thing that prevents fluid from going back into the reservoir. When the piston goes forward, the spring is supposed to pull it back straight, keep it upright tightly and then pressure supposedly keeps it seated. Anything that prevents that and having a strong seal from that blob such as some floating debris allows the fluid to seep back into reservoir. Slowly like yours or fast like rowdys. One thing that is interesting is the fluid in the relief port in your pict 8041. Unless some was spilled into it when removing the compensator valve, that passage should be dry unless the main piston rod seal is leaking severely. Attach file:  (4.87 KB) (4.87 KB)  (7.92 KB) (7.92 KB)

Posted on: 2010/10/3 20:36

|

|||

|

||||

|

Re: ANOTHER #%*!:( BTV failure

|

||||

|---|---|---|---|---|

|

Home away from home

|

Very interesting observation about the relief port. Seems I didn't notice that at the time, and thus I cannot definitively state with any certainty that is was due to spillage or not. My best guess however is that it was not from spillage however.

If this port is supposed to be dry, what is or is not going on inside the BTV then? The "pathway", I'm speaking about is the small cylinder inwhich the small rubber check valve moves within underneath the larger nut assembly what we put back into place.

Posted on: 2010/10/3 21:01

|

|||

|

||||

|

Re: ANOTHER #%*!:( BTV failure

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

In your pict 8039 it looks dry but maybe down low. That is why I asked if any spilled. What it does is to provide a path between the hydraulic seal in the fluid chamber and the secondary or vacuum seal on the canister side so that if there is any leakage, there is a place for the fluid to return to the liquid side rather than being forced into the vacuum side.

The port on the compensator valve is a machined hole and is large enough to allow the stem to tilt the rubber away. When the piston is retracted, a lip catches the end and pulls it back so fluid can return to reservoir. The underside of the assembly should also be machined and provide a very smooth surface that the lip on the valve blob can seal against. The rubber lip should be a good distance away from the hole all around and absolutely flat & sealed when valve is in the upright or closed position. When you do replace the valve, make sure the stem is on the back side of the plunger edge as shown in illustration--otherwise if in front, first time you step on brakes the stem will bend or break. Attach file:  (8.11 KB) (8.11 KB)

Posted on: 2010/10/3 21:08

|

|||

|

||||

|

Re: Bendix -Treadle Vac - Failure and Fix

|

||||

|---|---|---|---|---|

|

Home away from home

|

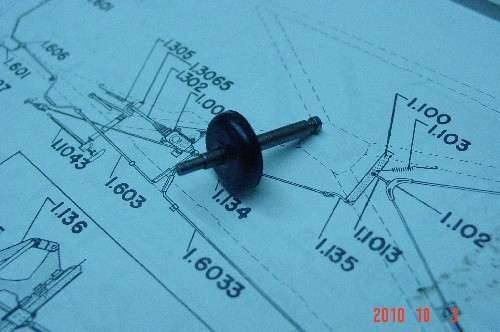

What concerns me is the compesator port valve stem pictured in DSC08042. It does not look like the port valve stem that is from my 56 Executive. The bottom appears to be very flat rather than hemisperical. Also mine has NO reduced diameter on the bottom 1/4 inch as is shown in your pic.

What we need is a close up of the 'damaged O-ring'. THis compensator port valve is THE MOST CRITICAL part of the BTV.

Posted on: 2010/10/3 22:38

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: Bendix -Treadle Vac - Failure and Fix

|

||||

|---|---|---|---|---|

|

Home away from home

|

Look at 'picture4' in HH56's post just above this one. U will see that the bottom of the 'O-ring" is much more hemispericaly shaped than the DSC08042 pic which is rather flat on the bottom.

I have suspected all along that the compensator port in the rebuilds are faulty. Somekind of RE-fit part from some other source maybe not even auto related nor hydraulic related. If the compounding of the replacement compensator port rubber is wrong then very likely the DOT3 or even the DOT5 brake fluid maybe causing the damage. We need some more good pics of the compensator port valve pictured in DSC08042.

Posted on: 2010/10/3 22:44

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: Bendix -Treadle Vac - Failure and Fix

|

||||

|---|---|---|---|---|

|

Home away from home

|

See DSC08040 pic of the gasket for the reservoir lid. Look closely at the hole for the 'relief port'. It would completely seal off the reservoir from the port onece the lid is secured. The gasket hole i believe needs to be cut away so as not to seal it from the reservoir.

Posted on: 2010/10/3 22:57

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: Bendix -Treadle Vac - Failure and Fix

|

||||

|---|---|---|---|---|

|

Home away from home

|

I don't believe the "relief port" is any issue here. In fact i see absolutely no way that any fluid could ever travel UP the port. The end of the vacuum power unit that mates to the master cylinder has no vacuum seal. When vacuum is applied to the power vacuum unit then vacuum is also against the plunger seal at back of the master cylinder. SO, any fluid between the master cylinder and power unit would get sucked into the power unit and no way can it be forced UP the "relief port".

The "relief port' is not a relief port. It is a gallery so that fluid can travel FROM THE RESERVOIR, DOWN the 'relief port' to the seal in the back of the MC to keep the seal lubricated. Either way, "relief port" or lube gallery, regardless of wheather fluid travels up or down the "relief port", nor for any other concept of the function of the 'relief port' the gasket as supplied in the kit and as pictured in DSC08040 should not seal the reservoir from the 'relief port'. I believe the gasket for the 'relief port' should be trimmed away toward the inside of the reservoir.

Posted on: 2010/10/3 23:06

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||