|

Re: generator troubleshooting

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

You need to measure voltage across the battery with engine running at a fast idle while shorting the field wire to ground. If that is where you measured and grounding the field wire did not increase the output significantly and changing the regulator made no difference then chances are the generator is the problem. When the field wire is grounded the generator should have an output several volts above standing battery voltage.

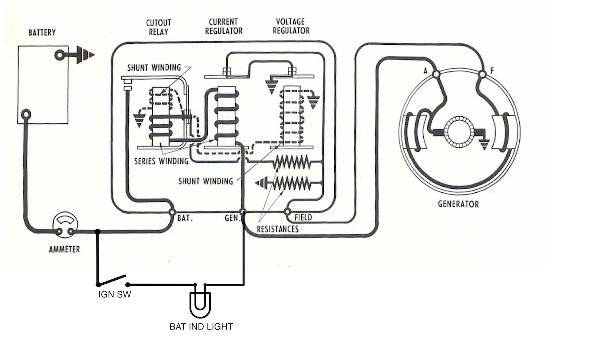

The fact it does not go above 12v would indicate the generator does not have near the output it should and you are most likely measuring just the battery voltage. I can't tell in the photo if you have a protective cover band over the brushes but if so you might snap the cover band off the generator case and check that the brushes are not worn down or make sure one of the brush holders has not stuck and is keeping a brush from making contact with the commutator. If no band or if all appears OK with the brushes then a generator service is next. Here is a generic diagram of a typical generator circuit with an indicator light. The Clipper is also wired this way (without the ammeter) but bulb is connected via splices in the main wire loom to other wires going to the components instead of direct connections. To light the bulb, one side of the bulb gets battery voltage from the ign switch. The other side of the bulb is connected to the armature in the generator and gets a ground thru the generator windings. With the engine off, when ign key turns on battery supplies voltage to the bulb and ground is provided thru the generator windings so the bulb lights. When the engine starts and generator turns fast enough it starts putting out a small voltage developed from residual magnetism on the field shoes which is enough to close the cutout relay in the regulator. That relay connects the generator to the battery and once generator is connected the field goes to full strength and generator starts full regulated output. When closed the cut out contacts also short across the bulb making the voltage equal on both sides to make sure bulb goes out and stays off. Everything stays this way as long as the generator is providing a proper voltage out. When the engine stops or generator no longer puts out enough voltage the cutout relay opens and bulb lights again. If the generator is turning slowly such as at slow idle and is right at the point of starting to put out enough voltage the cut out relay comes in and drops out making the light flicker or even a constant dim light if the generator is only putting out a small amount of voltage -- not enough to close the relay solidly but still enough difference between battery voltage and the small generator output voltage to make the light come on..

Posted on: 2019/9/23 13:18

|

|||

|

Howard

|

||||

|

||||

|

Re: generator troubleshooting

|

||||

|---|---|---|---|---|

|

Home away from home

|

If it's like Delco. You should have 13 to 14 volts at the battery.

I gave up . and went 1 wire alternator

Posted on: 2019/9/23 23:13

|

|||

|

Riki

|

||||

|

||||

|

Re: generator troubleshooting

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

I substituted a voltage regulator in the car I had and that did nada for me. I pulled the gen and took it to a local electrical rebuilder in a nearby town and the overhauled the generator.

I picked it up a week ago and put the car back together yesterday and that got me going again. I tried to order the one wire alternator from a place called Quality Power and ended up getting a unit for a 56 tbird, totally the wrong thing. so I sent it back. I contacted Powermaster tech support and they recommended a different unit so I may go that route in the spring. One of the other posters here mentioned a one wire alternator, just wondering what unit you used and how that worked out. For the poweremater units different size pulleys are available, was wondering if you ran int any issues installing this unit??

Posted on: 2019/10/17 15:29

|

|||

|

ClassicCrusier

|

||||

|

||||

(170.90 KB)

(170.90 KB)