|

Re: Connecting Rod Alignment?

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Assuming the rod isn't bent, the small end will center on the wrist pin when the big end is centered on the journal. This is a babbitt engine and the babbitt on the side faces of the rod control the end play and centering of the big end on the journal. Are you sure all the rods are installed the correct way, and if i remember right, even and odd numbered rods are different -- make a very close examination of them, and check your parts book to confirm that 2 different rods are used. And all the stamped rod #s should be on the same side of the engine.

Posted on: 2008/4/5 22:16

|

|||

|

||||

|

Re: Connecting Rod Alignment?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Follow Owens advice FIRST.

IF the rod is bent the piston will show an abnormal wear pattern. The onlyy spec is to have the wrist pin bore and big end bore parallel. I don't know what spec Packard used for crank end-play but the .005 sounds about as tight as it should be.

Posted on: 2008/4/5 23:19

|

|||

|

||||

|

Re: Connecting Rod Alignment?

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

I believe the rods to be correctly installed. All eight rods are numbered sequentially 1-8 starting at the front with their number stamped on the driver's side of the cap and rod as they should be. There is one rod that appears to have been "borrowed" from another engine and re-numbered which I would expect in a 78 year old engine.

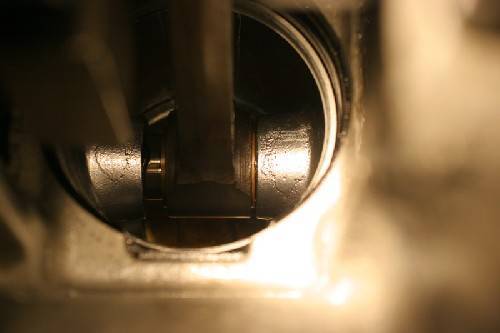

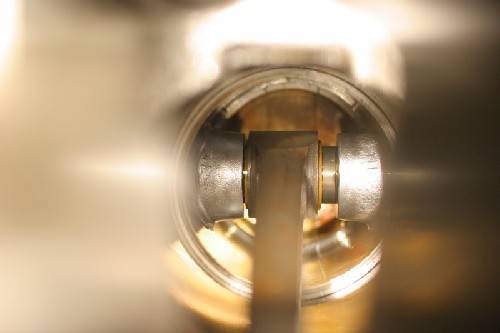

So I guess my best plan of action is to pull the piston with the rod that's farthest off center, check the rod for "true" and the piston for abnormal wear. I suspect the problem stems from where the rod sits relative to the side faces of the babbitt. I had to send the #2 rod off to the shop to repair a babbitt failure in the cap (picture). I am trying to avoid new rings so I am reluctant to disturb too many pistons. This engine has only about 9,300 miles on a fresh rebuild so I was planning to re-use the #2 rings. #2 piston shows only light scuffing on the sides of the skirt and the bore looks great (no ridge at top).

Posted on: 2008/4/6 7:15

|

|||

|

||||

|

Re: Connecting Rod Alignment?

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I don't recall ever seeing a Packard specification for crankshaft end play for that particular engine, but I concur with PackardV8 that what you have seems reasonable. For example, the specification for the big 356 engine starting in 1940 is 0.003" - 0.008".

Posted on: 2008/4/6 8:00

|

|||

|

||||

|

Re: Connecting Rod Alignment?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Pay close attention to the rod and main caps as u remove them. There could be VERY thin shims between the mating surfaces. DO NOT loose any or get them miexed. I don't care if the engine has only 10K miles on a fresh rebuild it could still have shims.

Posted on: 2008/4/6 8:39

|

|||

|

||||

|

Re: Connecting Rod Alignment?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Also check the wrist pin clearence. A loose wriste pin will usually make a deep clacking sound at IDLE when COLD and go away at higher engine speeds. From the looks of the pin bushing in one of your pics i am suspicous of wrist pin bushing issues.

Posted on: 2008/4/6 8:43

|

|||

|

||||

|

Re: Connecting Rod Alignment?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Just out of curiosity, do u know who made the pistons????

Posted on: 2008/4/6 8:46

|

|||

|

||||

|

Re: Connecting Rod Alignment?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Since u have an odd rod in the engine, i would go back and look at Owens first bit of advice and double check what is in the engine based on his advice/ according to the manual.

U do have a manual don't u???

Posted on: 2008/4/6 8:49

|

|||

|

||||

|

Re: Connecting Rod Alignment?

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Just to note there is no such thing as a shop manual for this and earlier years. If you could afford a Packard, you took it to the dealer. There are however and available as reprints the Service Letters to dealers which no owner should be without.

Posted on: 2008/4/6 14:31

|

|||

|

||||

(21.17 KB)

(21.17 KB)