|

Re: Type of lacquer

|

||||

|---|---|---|---|---|

|

Home away from home

|

A bit of finish history...

The old lacquer and enamel finishes were a fantastic improvement over their brush-painted predecessors. Prior to 1924, vehicles were painted using the same carriage-builder method used for decades. Not familiar with that method? Check out this explanation of the paint process from an early advertisement of the Studebaker Brothers Carriage Manufacturing Company in South Bend, Ind.: "Studebaker Finish! The most perfect, lasting surface of paint and varnish possible to put upon carriages. As the most vivid means of suggesting all the processes that culminate in a Studebaker finish, the accompanying panel was prepared. It illustrates the twenty-two successive stages of finish as they appear on every Studebaker carriage. But, there are other steps typical of Studebaker thoroughness that cannot be pictured: the chemists tests of oils and pigments; the careful preparation of the wood to take its finish properly; the repeated hand rubbing (sanding and polishing) to get smoothness; the perfect drying of the coats, an item that means fifty-two days of valuable time. "More important than all of these, is the long, unequaled Studebaker experience, coupled with the thoroughgoing principles practiced throughout this 101 acre plant, from the executive office to forge, make it safe for us to lay bare these manufacturing policies -- safe for you to trust the name of Studebaker -- Studebaker Finish Endures." Can you imagine? Fifty-two days to paint a carriage! (Cycle times obviously weren't important then!) Other documents I've found regarding various manufacturers weren't much different. The drying times were extremely slow, and vast drying sheds of a very sanitary quality were employed to accomplish the task. But durability was poor. The Japan varnish topcoats succumbed to ultraviolet rays in two to three years. When the automobile came along, it was little more than a motorized carriage. But the use of more sheet metal required the use of corrosion-resistant primers, primer surfacers and new sealers --so these new products were added to the centuries-old system already in practice. And this system was used to refinish the new and soon-to-be mass-produced automobile -- a system that was woefully inadequate to the task at hand. In the 1920s, several paint manufacturers were involved in the development of nitrocellulose lacquers. But one manufacturer in particular stands out. Have you ever heard someone say that many inventions come from mistakes? It's true. In 1921, DuPont was a leader in nitrate movie-film manufacturing. "So what," you say. "Did I skip a page or something?" Keep reading. It'll make sense soon enough. Little did the company know it was about to discover how to unlock the massive painting bottleneck auto manufacturers were suffering from. It happened on a hot Friday afternoon in July 1921, when a worker at the DuPont film plant left a drum of gun cotton (cotton fibers treated with a nitrate solution) out on a loading dock during the very warm weekend. Monday morning, concerned workers brought the drum inside and opened it up. To their amazement, what they found wasn't gun cotton, but a clear, viscous liquid. This liquid became the foundation of nitrocellulose lacquer, which was the leading automotive finish for nearly 50 years. Two years later, in 1923, the 1924 Oakland (a precursor of the Pontiac) was the first production automobile to be spray painted. Of course, many improvements had been made along the way in regard to force drying, application methods and product formula, but this initial discovery and subsequent use for spray painting unlocked the tremendous production improvement. During the 1930s, both nitrocellulose lacquer and alkyd enamel were used in automobile production. Many manufacturers also used combinations, offering black enameled fenders and a selection of colored lacquer bodies. Chrysler, Ford, Nash, Willy's and Studebaker used alkyd enamels on their offerings, while General Motors and many smaller independent manufacturers used lacquer. These products and their derivations were used well into the '70s by both OEMs and the refinish industry. --- Mike West

Posted on: 2017/6/5 23:43

|

|||

|

Rob

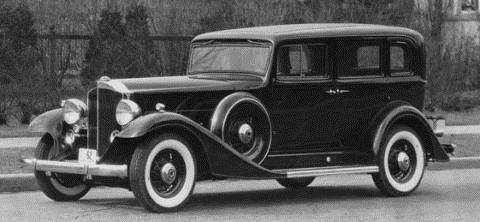

1930 Custom 8 Club Sedan |

||||

|

||||

|

Re: Type of lacquer

|

||||

|---|---|---|---|---|

|

Home away from home

|

Packard used lacquer right to the end in '56, when production went to South Bend in '57 all Studebaker-Packards continued with the Studebaker enamel finishes

Posted on: 2017/6/6 5:03

|

|||

|

||||