|

Re: 1940 Super 8 Valve Work

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

The "star washer" type item is to prevent valve assembly rotation. It may not be missing, oft times they remain stuck in place.

Posted on: 4/9 15:16

|

|||

|

||||

|

Re: No Compression

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Dimensions would be nice for confirmation but by profile it appears to be the hydraulic lifter gauge for the 356 motor. Simply remove the hydraulic plunger unit from the cam follower and insert the gauge. Insure the cam follower is on the cam lobe baseline. Insert the valve and grind the end of the stem if necessary to give a clearance of between 0.030" and 0.070". Take care with the stem grinding, you can do it nicely without specialized equipment but you want it dead flat and square to the stem, a little polish wouldn't hurt. Obviously any seat work should be done first.

Early 1950s editions of Motors Manual have a fairly detailed section specific to these Wilcox-Rich hydraulic units. If you have power valve and seat grinding equipment, it will give a fit and finish superior to what you can achieve with hand lapping. If not and the surfaces need attention, hand lapping can give a good service life.

Posted on: 4/5 19:20

|

|||

|

||||

|

Re: 1956 Caribbean Production

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

All of the so-called build slips I've seen are actually the shipping order copy which contains the "build" details. If that's the case, I believe the date stamped is the date shipped. But I'd recommend you ask Roscoe or Stuart Blond to be sure.

Posted on: 4/5 17:01

|

|||

|

||||

|

Re: Rarest Car Options?

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I one installation I've seen that comes immediately to mind was on a 1951 Patrician. I'm sure I posted pix of it on thus site at the time.

Posted on: 3/25 16:48

|

|||

|

||||

|

Re: Burr Ripley L6 filter - how to modify inside filter

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Glad to hear it so count me in, I'll be wanting one or more L6 cartridges.

Posted on: 3/25 15:08

|

|||

|

||||

|

Re: Resurrecting a 1951 Henney-Packard Parts Car

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

As I was taught back in high school auto shop, to get the effect of the servo action from this type of Bendix brake, when the two return springs are different the weaker spring goes on the primary shoe regardless of front or rear brakes.

Posted on: 3/23 22:20

|

|||

|

||||

|

Re: Final gear ratios for 5th, 6th, and 7th series Packards.

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

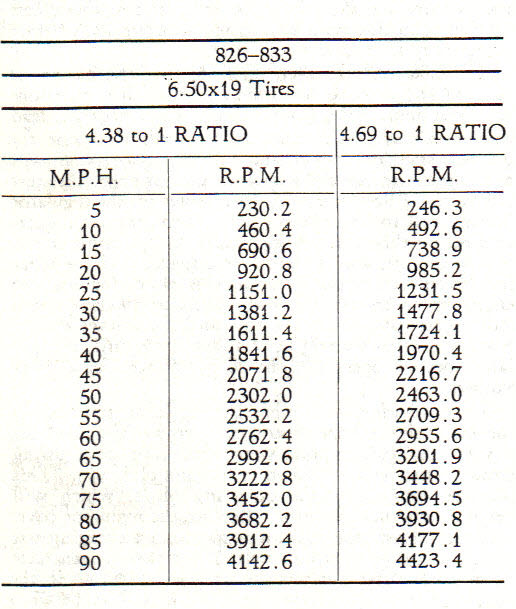

As you consider the effect of the rear axle ratio on rpm and road speed, don't forget to take into account the effective tire diameter.

Here's some PMCC data related to 19" tires driven thru the 4.38 and 4.69 ratio rear axles. Attach file:  rpm vs mph.jpg (112.05 KB) rpm vs mph.jpg (112.05 KB)

Posted on: 3/21 13:05

|

|||

|

||||

|

Re: Burr Ripley L6 filter - how to modify inside filter

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I don't know the answer to your question but will be watching this closely for responses as I also have a 1934 with the one-year only L6 Purolator and am using the Burr-Ripley conversion. I've used the last of my Ripley cartridges some thousands of miles ago and am not aware of a current source and apparently no one picked up the Ripley tooling.

I don't believe simple soldering will give sufficient strength to the threaded nipple. I am considering replacing the filter with a length of copper pipe to retain the oil circuit thru the cooler, and just run without a filter. With only 3-500 miles per year and an annua oil change I don't think there is much downside to running without a filter.

Posted on: 3/17 7:57

|

|||

|

||||

|

Re: Chrome disc wheels on a 1932?

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Depending on the type of racing, one advantage that wire spoke wheels can offer is that they allow better cooling airflow around brake drums.

Posted on: 3/14 16:01

|

|||

|

||||