|

Re: Bob's '55 Patrician Blog

|

||||

|---|---|---|---|---|

|

Home away from home

|

I'll let others answer the other more technical questions but it is not necessary to freeze a roll pin. It should tap in without ever having to do that and that is the entire point of using roll pin in the first place.

Posted on: 2019/3/2 16:30

|

|||

|

||||

|

Re: Bob's '55 Patrician Blog

|

||||

|---|---|---|---|---|

|

Home away from home

|

The camshaft rotates CW. The oil pump takes considerable torque to turn. The drive gear on the dist. is thus pushed down hard by the turning of the engine and is supposed to rest on the machined spot in the block. Otherwise the considerable thrust generated by that right angle drive gear set would have to be supported by a thrust bearing in the dist.. It is not designed to work that way. Remove your shims and continue as if nothing ever happened.

Posted on: 2019/3/3 3:00

|

|||

|

||||

|

Re: Bob's '55 Patrician Blog

|

||||

|---|---|---|---|---|

|

Home away from home

|

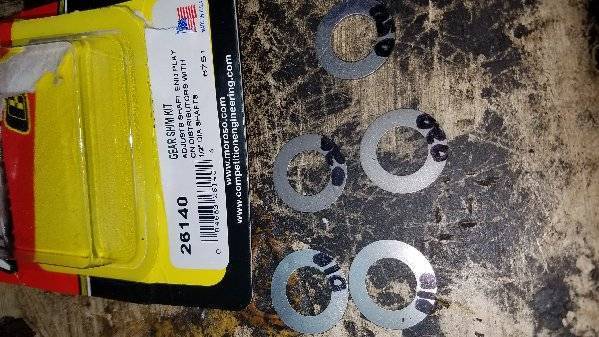

Thank you Ross.

I have removed the shim and back to where I started. There is a risk to using Google to address concerns for these cars (like what seemed to be excessive dist end play) as the generic answers out there may not apply. I didn't think the end of the gear was supposed to touch the block. With your description, "large" end play wouldn't matter with the downforce from the cam gear forcing block contact. Does the gear wear enough in that regard that it has to be replaced? The wear marks on the dist gear teeth seem properly centered so I'm guessing if wear can be an issue, I haven't got to that point yet. thanks again. Back to sleuthing to see why I am having this intermittent miss on random cylinders at idle.

Posted on: 2019/3/4 13:29

|

|||

|

Bob

1955 Packard Patrician Sapphire Blue |

||||

|

||||

|

Re: Bob's '55 Patrician Blog

|

||||

|---|---|---|---|---|

|

Home away from home

|

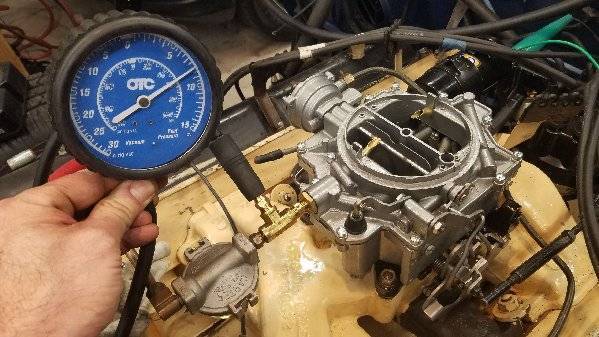

Progress!

Got my 4GC back from Daytona. Hard to believe it is the same one that I sent them, it looks awesome. (see post #43 on page 5 for a before photo). Installed it and they had a note in the box saying that the right fuel pressure was 4.5 - 5.5 psi. So after installing it, I plumbed in my gauge to measure. It was about 8psi using the mechanical fuel pump. Seems to run decently with that higher pressure. The fuel pump I have is what I got from Advance auto parts with cross reference in the Parts X-Ref section. Not sure if I need to find a way to reduce the pressure or just accept what it is for now. Once I started it up, the car did not exhibit the pronounced, yet random miss that I saw before. I don't know if was the new Carb, the fact I re-rebuilt the distributor, or that I greatly separated spark plug wires 5 & 7 from each other. Can't complain, as it is running much more smoothly at ~450rpm. Was able to take the car for a spin today. Here is a pic of my 18yr old son giving her a spin around the block. I still feel like it should have more acceleration than it does, it is fairly 'clacky' in noise, but maybe that is because there is no hood or front clip. Assuming I don't have to worry about the fuel pressure, I am going to spend my time tweaking carb mixture and timing to maximize vacuum. Good day overall.

Posted on: 2019/3/23 21:43

|

|||

|

Bob

1955 Packard Patrician Sapphire Blue |

||||

|

||||

|

Compression test

|

||||

|---|---|---|---|---|

|

Home away from home

|

For documentation sake, I wanted to record the latest.

I have been driving it around the block lately. It starts right up and idles well. There is a random shudder or miss at idle as well as higher RPMs. Can't figure out if it is carb or distributor but I know it can be smoother. Decided to do a compression check. Attached photo shows the plugs and the peak cylinder pressure. Test was done with a cold engine, all plugs out, and throttle block wide open. Pressure ranged from 130psi- 150psi, the plugs look good to me. Not many miles since re-rebuild, maybe 5-10 of actual driving, but a fair amount of time of running in the garage at 1000-2000 rpm. I think I am still in the breakin period but just wanted to record this point in time. I'd say the acceleration is sluggish. I expected more after the rebuild so still tweaking carb mixture settings to get good vacuum. It is around 16 right now and I think I may have a vac leak that is preventing me from getting closer to 18 or so. Still looking.... Also, the car will roll in the driveway when in Park. Not sure how to address in the transmission to address this. Parking/e-brake isn't very effective either as it bottoms out when I pull the brake handle all the way out. Not wanting to be a troglodyte (a la Ross), I am working on using the rear star wheels to get adjusted as per Ross's procedure in the main forums.... :)

Posted on: 2019/4/18 21:46

|

|||

|

Bob

1955 Packard Patrician Sapphire Blue |

||||

|

||||

|

Re: Compression test

|

||||

|---|---|---|---|---|

|

Home away from home

|

FYI. There is still a miss/shudder at idle that is also perceptible at higher rpms. There is also a little rpm surge at idle so I am working on the assumption there is a vacuum leak somewhere. But no luck in plugging carb fittings, spraying starter fluid all over manifold, carb, etc.

I was curious about oiling. The oil pressure at cold, high idle of 1100rpm is ~45-50 psi with Rotella T4 15W-40. The link below has some video of the engine at cold and warm idle as well as a few with the rocker covers removed. There are no gushers of oil, but you can see the drips off the rocker arm at each rocker location. You can see the shudder in most of the videos, and maybe hear it but the audio isnt great. Just thought seeing the rockers moving was cool so wanted to share and also solicit any ideas as to find the source of the shudder. thx https://www.youtube.com/channel/UCXxvWDoVWUSusn7JVgi1Fkw

Posted on: 2019/5/14 21:57

|

|||

|

Bob

1955 Packard Patrician Sapphire Blue |

||||

|

||||

|

new videos

|

||||

|---|---|---|---|---|

|

Home away from home

|

Added a few new videos to the youtube link above, still trying to find what I believe to be a vacuum link. 2 of the videos are of the vacuum, oil pressure and RPM. Best I could adjust the carb is to get ~17" at 450rpm. Timing checked at 6 deg BTDC, Dwell is 30deg

The 3rd is showing the air coming out of the tappet cover breather tube. It is very humid here in Houston, so maybe this is normal but seems like a lot more condensation than I would expect. Just documenting these things here for future reference. Got the parking brake much closer to useable now. Followed Ross's and the manuals advice and it will hold the car just before the parking brake handle comes to a stop. The Vacuum videos are with the carb vac check valve (in the rear) removed and vac gauge hooked up to that port via hose barb connection.

Posted on: 2019/8/12 8:43

|

|||

|

Bob

1955 Packard Patrician Sapphire Blue |

||||

|

||||

|

Cylinder Leak Test

|

||||

|---|---|---|---|---|

|

Home away from home

|

After running out of ideas as to what could be a vacuum leak, I decided to take a step back and see how the engine is running overall.

Observations: -Engine starts right up, carb choke works well -Fast idles around 1100rpm, idle when warm at 450rpm -idle vac is ~17", high speed ~20"-21" -Right (passenger) exhaust is noticeably more "forceful" -than left; even when exhaust bypass valve is fully open after warm. Feels like more air is coming out and 'pulses' for each cylinder firing are more distinct -Also hear a low frequency 'whoom' every once in a while that corresponds to a slight dip in rpm and vac -Rpm doesnt vary at idle like it is going up and down. But steady at 450rpm and then drops every once in a while, then goes back to 450rpm. Same behavior at higher rpm; it's not an oscillation but a steady-ish rpm that drops every once in a while (once every second or two) -Ran a Cylinder Leak test for more info. fully warmed engine, pulled all plugs. Results below. Repeated test for cyl #7 the next day to be sure. Redid compression test just for #7 (battery was getting finicky so couldnt do them all) and it was 135psi (all plugs out, choke fully open). Pressurized cylinder tester at 90psi Cyl Press % leakage 1 88 2 3 86 4 5 88 2 7 79 12 2 87 3 4 88 2 6 86 4 8 85 6 Audible leakage for ALL cylinders was in Oil fill tube, no sounds in carb, exhaust, or bubbles in radiator

Posted on: 2019/8/17 21:19

|

|||

|

Bob

1955 Packard Patrician Sapphire Blue |

||||

|

||||

|

More troubleshooting

|

||||

|---|---|---|---|---|

|

Home away from home

|

Still working through a troubleshooting process on the miss at idle and at elevated RPM and documenting what I am doing so I can recall later in time if this happens again:

Tested all the spark plug wires for continuity; nothing interesting there. Listening to the exhaust pipes, the right (passenger) side is noticeably more 'forceful' than the driver side. I know the exhaust manifold riser valve can restrict this to some degree, but I have the spring removed so it is mostly open. (note, i manually close it when starting the car until it is warmed up). Have some muffler holes that were patched with tape so maybe there is some leakage on the driver's side The miss is audible from the right exhaust pipe along with a low frequency "whoom" sound at the sound of the miss (and reduction of rpm). I think this is telling me that my problem is not a generic fuel/carb problem or primary side ignition problem. Pulled the even cylinder plugs and 2,6,8 look normal. #4 looks too clean to be right; the insulator core is very clean. Started engine with #4 plug removed and touching block. Seems like a proper spark visually so I would assume it is firing in the cylinder. I also have lowish vacuum (oscillates between ~16"-~17")so maybe there is a vacuum leak in #4 air path that is causing a very lean condition. More to come, just wanted to write down what i did recently so I didnt forget. Next steps: pull right valve cover to see if anything weird going on with #4 intake valve. Also maybe use a spark tester to see if any difference between the plugs.

Posted on: 2019/8/29 11:32

|

|||

|

Bob

1955 Packard Patrician Sapphire Blue |

||||

|

||||

(347.44 KB)

(347.44 KB)