|

Re: 51Packards....52 Packard 200 Deluxe!

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Good news on the pump.

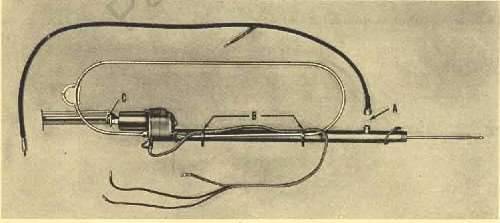

Quote: I have no idea if it's needed or not. Must serve a purpose if the engineers put it on there It keeps the nylon cord from tangling or getting damaged and also keeps grease and crap off so it doesn't mess up the mechanism. The old nylon could be brittle and if it is it will break easily so use caution. If it is the flat sort of dual pyramid shape stuff also look for divots or rough edges on the sides. If the mast sticks and the motor keeps going it usually chews a chunk out of the edges. Once the motor hits that point again the mast stops moving. I haven't found anything flexible and anywhere close to that shape to replace it.

Posted on: 2016/3/16 19:10

|

|||

|

Howard

|

||||

|

||||

|

Re: 51Packards....52 Packard 200 Deluxe!

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks Howard,

I figured the actual loop of tube was for that purpose. I was trying to describe the weird half circle of metal on the bottom of the tube loop. Not sure if that is supposed to help with reception or not. I'm also concerned with the nylon getting stuck. I will lube up the antenna the best I can and buy a proper antenna to fender rubber mount to keep water out of the working motor. I also mailing in my application for collector plates. In Wisconsin, you can get collector plates that do not expire. It takes a long time to get them, but I hope I have the application in early enough so I can drive the car around more this year!

Posted on: 2016/3/16 19:18

|

|||

|

[url=h

|

||||

|

||||

|

Re: 51Packards....52 Packard 200 Deluxe!

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

OK, I know what you are referring to and I don't know the purpose of that particular shape either except they all seem to have it. IIRC, there are some small holes in the edges of the thing so perhaps it is a drain and ventilation affair. Maybe someone has a definitive answer.

Posted on: 2016/3/16 19:32

|

|||

|

Howard

|

||||

|

||||

|

Re: 51Packards....52 Packard 200 Deluxe!

|

||||

|---|---|---|---|---|

|

Home away from home

|

Weed eater line wouldn't work for a replacement would it? Some of it comes in square shapes anymore.

John

Posted on: 2016/3/23 15:59

|

|||

|

||||

|

Re: 51Packards....52 Packard 200 Deluxe!

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I don't think weed eater line is large enough diameter -- at least none I tried was -- but IIRC Cli55er tried some nylon electrical fish tape on his later antenna which uses a round nylon. Don't remember if he mentioned whether it worked on his but it might be a possibility on the older shaped units. The round diameter might be enough larger than the flatter nylon that it could fit between the wheels and still work with the shape on the older units.

Posted on: 2016/3/23 16:15

|

|||

|

Howard

|

||||

|

||||

|

Re: 51Packards....52 Packard 200 Deluxe!

|

||||

|---|---|---|---|---|

|

Home away from home

|

I think my nylon insert is OK, its the tube it rides in that it rotted away in many places. If the half circle at the bottom really serves no purpose, all the better for me so I don't have to reproduce it. Hard to believe an engineer would add something that wasn't necessary though....

Posted on: 2016/3/23 17:41

|

|||

|

[url=h

|

||||

|

||||

|

Re: 51Packards....52 Packard 200 Deluxe!

|

||||

|---|---|---|---|---|

|

Home away from home

|

3-27-16

Saving the antenna project for a rainy day. Today was decent out so I spent a couple of hours with the car. I didn't feel like getting dirty so it was chasing electrical problems today. The fuel gauge used to work in the '51 from what I remember, but I do not know if it was accurate. I am using the gauges from the '51 in the '52 because they are in better shape. I tested power to the fuel sender and I have it so I grounded that wire to the trunk latch and the fuel gauge moved to FULL. I connected the fuel sender to the gauge and grounded the sender with some alligator clips. I moved the float up to simulate a full tank. The gauge moved, but only about 3/4. A couple of up and down sweeps did not improve my results. I took the cover off the sender. Looks like it has some corrosion in it. I was going to spray some electrical cleaner in there, but I figured I would ask here if that was OK to do or if there are any better options to try. Turned my attention to my license plate light. Surprisingly it worked after just a little clean up. I need a new lens for the light though. The edge is all broken off. Covers most of the bulb area so the weather says out somewhat. I bought a trunk light and installed it a while ago. It is not working. I played with it some today, but no real results. Power goes to the connector, but no power in the center button in the socket. If I move my test light around sometimes I get it to light away from the center. Cleaned it anyway with the same result. Can these be opened up and cleaned? I think it has a mercury switch which makes me nervous. My left turn signal works great, but my right one flashes quickly in the back and the parking light is very dim when flashing. I checked all over the rear taillight and do not see any problems there so I think the issue is in the front or the switch itself. When I first turn on the right turn signal I hear the flasher click twice then go silent and the rapid flashing starts. I noticed the left parking light bulb was glowing from the larger filament toward the top. The left one was gloving from the shorter lower filament. I reversed the wires on the right one and it was brighter with the turn signal on and didn't flash as fast, but still not right. I ran direct power to the bulb to simulate just the parking lights on and it was really dim. Tried running a wire from the ground on the battery to the bulb to see if it was a grounding issue, but no change.

Posted on: 2016/3/27 14:43

|

|||

|

[url=h

|

||||

|

||||

|

Re: 51Packards....52 Packard 200 Deluxe!

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Ground is most likely problem with dim bulbs. Even though you ran ground thru a good wire any corrosion in the socket or with the connection to any metal will show very quickly/. Parking lights should use the small filament, turn signals (and brakes) the larger. It is possible the wiring has been crossed or in some cases a wrong bulb can be inserted in the sockets and will be backwards or only one filament lights so it partially works.

Turn signals are dependent on the proper ohms being seen by the heater in the flasher. To little and it won't flash or if does is usually somewhat fast and too many won't flash either. The two times it flashed and nothing sounds like a bad bulb, wrong filament or very bad ground at either end. Also, if there is a bad ground at a socket it will try and find one where it can. With the dual filament bulbs that could mean going back thru the other filament, and out the wire and thru another bulb on the same wire and out that filament to its ground. Result is no flasher or if parking lights, very dim bulb(s). It is possible for the turn signal switch to be at fault but before going there I would shine up every ground point including inside the sockets. Use some contact cleaner and some abrasive, Nylon scrubs are good and then use some air to get any debris out. Some have even had to run extra wires to the front sockets because the ground thru the grill can be very poor. If all that fails then look to the switch. You can try some contact cleaner on the sender but don't drown the phenolic or when it gets wet at least blow it dry after moving the wiper a couple of times. Moisten the resistance wire and then move the wiper back and forth a few times while it is damp. If that doesn't help there is also a possibility the phenolic support has warped and the wiper is losing contact at the bad point because the resistance wire is not in position to make a good contact. The trunk light switch could be mercury or it could be a steel ball and set of contacts which have oxidized. Around 51 seems to be when they transitioned from mercury to the balls and there have been both types seen. The mercury is enclosed in glass so not serviceable inside. Just clean the contacts on the glass capsule is about all that can be done. Not sure what happens to mercury after it is in contact with some metals but sometimes even though it is sealed there is a layer of oxidation that builds on the contacts so they won't pass current. That was a problem with some modern medial equipt I used to work on. If it is a ball it may be possible to work the end crimp holding the switch cap off and remove the ball to clean everything.

Posted on: 2016/3/27 15:27

|

|||

|

Howard

|

||||

|

||||

|

Re: 51Packards....52 Packard 200 Deluxe!

|

||||

|---|---|---|---|---|

|

Home away from home

|

3-28-16

Thanks to Howard's ideas, I think I am pretty close to a diagnosis. One thing he mentioned was a bad bulb. I took the bulb out of the right front parking light and moved it to the left parking light and also to the taillights. Whenever I put this bulb in a socket, it would glow dim and cause the turn signal to flash dim and rapid. I put the left tail light bulb in the right parking light so I knew I had 2 good bulbs in the right turn signal circuit. The bulbs burned brighter and flashed almost at the right rate, but the flasher only clicked once. I reversed the wires on the front parking light and tried again. Now the flasher clicks and the turn signal worked! The only problem is it runs off the smaller filament instead of the larger filament like it should if I am reading Howard's comments right. I put the good bulbs in the left sockets and tried it and the turn signals worked. These were also running off the shorter filament. I noticed the bulb was loose and would cut off if I wiggled it. I think the spring is too weak to hold it in snuggly. I wrapped some aluminum foil around the bulb and reinserted it. That seemed to help some. I wired the right parking light back the way it was to run off the longer filament and rewired the left parking light to run off the longer filament. Now when I tried the turn signals with good bulbs in each side, they would blink but the flasher would not click. So from what I can tell, I have a bad bulb (have to order a new one to confirm) and the turn signals will only work off the shorter filament and not the longer one. I also have a bad socket in the front parking light which is ironic because that was the side that was originally working! I also tried to clean the fuel sender. I can hear it rub as it travels, but I noticed that right at the turn the spring strip is broken. It does not appear to affect it but maybe it lets it pull away a little and it loses contact. I had all of my alligator clips tied up in the front end so I couldn't try it. Maybe I could drop some solder on it to glue it back together?

Posted on: 2016/3/28 18:29

|

|||

|

[url=h

|

||||

|

||||

(59.41 KB)

(59.41 KB)