|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Home away from home

|

Forgot to ask.

The Compensator Control Box for my T/L is a 56 model. All other parts are for a 55, of course. I know the 55 and 56 have their differences but will this 56 model work on my system? Do I just ignore the two connections for the 56 limit switches like they did when they put this switch in the car. Remember, I have never driven this 400 so I have no idea if it worked when last running.

Posted on: 2016/1/4 22:00

|

|||

|

Stewart Ballard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

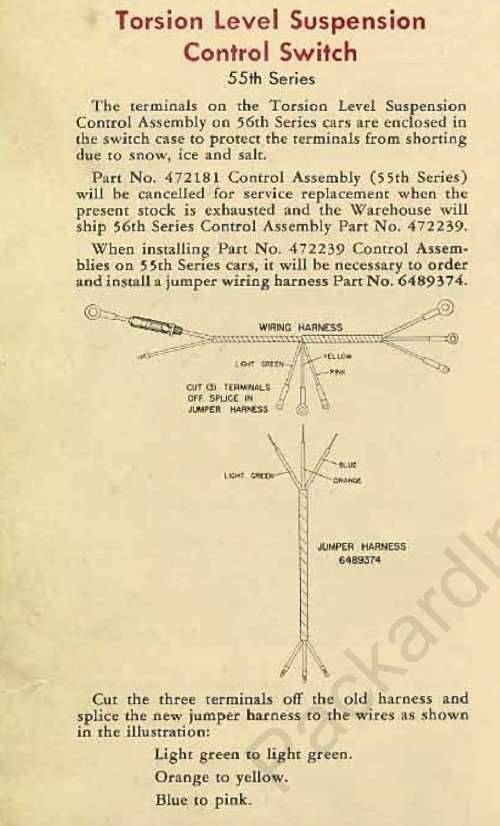

Here is Packards official instructions for installing the later switch. You do ignore the dual socket outside terminals as they are just tie points for connecting one side of the 56 limit switch wiring to the portion of loom continuing on to solenoids. They do not connect to anything inside the switch.

You didn't mention if your new switch is original or one of the solid state reworks. If solid state verify from the vendor if the polarity of the switch will work on your car. 55 reworked switches were originally specifically pos gnd and 56 switches was for neg gnd. I have no info on how the rework was done or know if that limitation still exists.

Posted on: 2016/1/4 22:39

|

|||

|

Howard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks for the info.

The compensator control box that I have came with the car. I have no idea if it was ever reworked (I did get a new limit switch). I guess I am opening up another can of worms as I am planning to change everything to negative ground. Once I get the T/L re-assembled we will find out if its positive or negative ground won't me. While I have your attention. What is the best way to reattached the short link arms that to the main T/L rods on each side? When I disconnected everything last year I simply removed the motor and unwound the rods to disconnect. Is that the best way to reconnect?

Posted on: 2016/1/5 13:55

|

|||

|

Stewart Ballard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

The original switch doesn't care about polarity. It has small heater windings that bend a bimetal strip for the time delay so doesn't matter which end sees ground or voltage. As I understand it the reworked boxes eliminated the heaters and bimetal portion and use a solid state timer circuit for the time delay. Those are the polarity specific boxes.

Not sure I am following which short link arms you are asking about -- the transverse bars between the compensator assy and ball end lever on the short torsion bars or the short torsion bars into the load link at rear. If it is the transverse bars a load or some means of moving the rear axle closer to frame has to be applied enough to compress the suspension and get it more toward neutral or center of travel. That will rotate the ball joint levers on the end of short bars toward the center of car and away from inside the frame. Once those are a few inches out you can block them and keep the levers from moving. The compensator can be rotated so the center "V" lever is positioned for length. Once lever ends are positioned the transverse bar sockets should clear the frame and ends will slide over both ball joints to be connected. Once bars are connected then remove the blocks and when some body weight is back on the suspension all should work. I wouldn't try moving the suspension via the compensator with no body weight on the car. It will stress things considerably. If it is the short bars into the rear load link then again weight or some kind of compression has to be applied to move the axle end of load link up in the bracket. The hex the short bars insert into should then be clear and accessible in the frame bracket. You might read thru Cli55ers blog to make sure I am correct but IIRC he had a unique way of compressing the suspension. Believe his 4 wheel drive pickup was the right height so he could drive it over his padded Packard frame a few inches so frame would be held down by the bumper. Once the frame couldn't move upward he used a floor jack under the rear axle to move the axle and bars to the more centered position. Don't remember if he connected bars while it was held this this way or just chained the suspension in the centered position and then removed the truck and jack.

Posted on: 2016/1/5 14:32

|

|||

|

Howard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Home away from home

|

Its the transverses bars with the ball joints on both ends. I am at work and do not have my Packard brain on.

So its safe to reconnect everything without any weight on the chassis. Just don't try to run the motor after its reconnected. Before I reconnect the bars I would like to test everything to make sure it works as it should. Not just the motor but also the control box.

Posted on: 2016/1/5 15:42

|

|||

|

Stewart Ballard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

You can move things a bit with the compensator with no weight on the main suspension just to test it. I would just be careful not to move more than a small amount because it puts a huge amount of stress on the compensator when nothing else except the short bars can move.. You will have to actuate the control switch lever by hand just enough to have it start and then let off after compensator moves the center "V" link and short bar levers a few degrees.. I would not leave it on long or try to go to max so the transverse bars hit the limit switch because the short bars will twist but don't have the strength to overcome the main bars. The compensator can't level anything unless the weight of the body load is on the main bars and things are somewhat balanced and load arms are within the working range. Then the short bars are able to add or subtract force on the rear load arms to level the car.

Posted on: 2016/1/5 16:26

|

|||

|

Howard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I moved things with no weight on frame. Nothing bad happened. You just won't notice anything other then the short transverse bars moving. The weight of the truck was to get the drivers front suspension back together after I had taken it apart. The arm was still in the lower a-frame, but yes I used my truck over the corner of the frame and jacked the lower arm up and reconnected to the top arm. We used the winding tool after my straps broke holding the arms up.

Posted on: 2016/1/5 16:32

|

|||

|

1937 Packard 138-CD Deluxe Touring Limousine

Maroon/Black 1090-1021 [url=https://packardinfo.com/xoops/html/modules/registry/View.php?ID=232]1955 Packard |

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Home away from home

|

I have been going through a few of the Service Counselors here on the site. Am looking at all the information about the T/L.

I found the brief article describing installation and testing of a 56 control box into a 55 Compensator (like mine). Of course all the information assumes the car is in one piece while mine is not. I don't have a brake switch or on/off switch on the dash. How do I test the whole unit (control box and all). Do I just hook up the battery to the red wire (starter led), ground it and then work the control box? ...or do I have to ground the left or right connections within the 56 control box as described in the Service Counselor. The compensator and motor were rebuilt by Michiana Packard so I am not concerned about it working. ITs all the other electrical components that I need to test before I can say I am done with this.

Posted on: 2016/1/13 14:22

|

|||

|

Stewart Ballard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

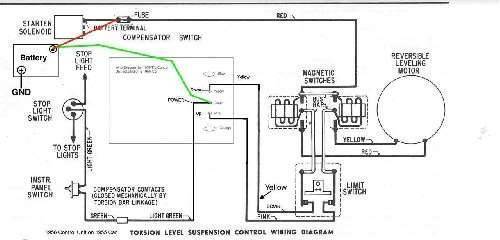

I don't know where this schematic came from but someone drew the 55 circuit with a 56 box. I've borrowed it and added a battery and show the needed wires strictly for your situation.

Since you just want to test and don't have the brake switch or on/off switch ignore those for now. Wire the rest of the circuit from the control box thru limit switch and solenoids to the motor as per stock. To bypass the other components go directly from the battery as shown...Ground the battery positive terminal to the frame. Am assuming the components are properly mounted. If so the control switch and motor will pick up ground the normal way. If they are not mounted then you will need to connect a good ground from the battery to both components. Connect the negative terminal of the battery to the fused red wire feeding solenoids and motor and use another wire to connect to the light green center terminal of control box. Nothing else is needed. When the wires are connected you can manually move the small lever on control box to simulate the action of the linkage. I am still of the opinion it is not a good idea to stress the system to the limits while not having a load on the bars. You can start things moving and test the action of limit switch by pushing the limit switch actuator lever with a screwdriver or something as if the bar had actually hit it.

Posted on: 2016/1/13 15:06

|

|||

|

Howard

|

||||

|

||||

(67.19 KB)

(67.19 KB)