|

Re: need a close up photo of a 39 120 running board

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

I've seen the "Rino Deck" application and I do not think you will be pleased.

Posted on: 2013/12/8 15:30

|

|||

|

1939 - 120 ,4 dr / overdrive

|

||||

|

||||

|

Re: need a close up photo of a 39 120 running board

|

||||

|---|---|---|---|---|

|

Just popping in

|

David, I had a similar situation with my 1940 Club Coupe,

I filled in all the holes with epoxy, the kind you knead together, sanded it all down and sprayed it with spray can rubber from Home Depot, using multiple coats. The name of the product is Dip-It spray rubber. It lokks really good, it doesn't have that texture that truckbed liner has. It's been on there a couple of years and still looks good. The whole deal cost me about $30 and some labor. Wayne

Posted on: 2013/12/8 15:43

|

|||

|

||||

|

Re: need a close up photo of a 39 120 running board

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks Wayne, I will look into that product. How did you go about removing the old vulcanized rubber? That looks like the largest task.

Posted on: 2013/12/8 18:59

|

|||

|

||||

|

Re: need a close up photo of a 39 120 running board

|

||||

|---|---|---|---|---|

|

Home away from home

|

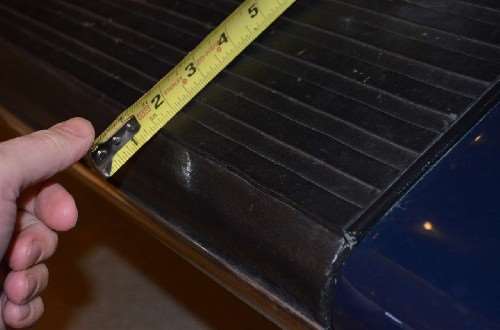

David,

The original pattern generally follow the longitudinal lines stamped into the boards themselves. The rubber pattern includes alternate high and low features whose widths are each 1/2". The rubber follows this pattern from front to rear, but the ends come to points a inch or two from the front and rear fender. Hundley Acuff's boards are beautiful, no doubt. Until I can afford them, I'll keep what I have. I considered truck bed also and it gives a very respectable result. However, i fortunately found an actual rubber truck bed liner mat that had the same pattern, with the exception of the pointed ends. I cut the mat to cover only the flat top surface. Rolling it up for the portion under the car and down at the outer edge proved bad for two reasons: 1, the pattern does not go to the edge and 2, the mat was too thick to bend at the small radius. I glued the mat down with a great 3M product, filled the outer and inner edges with a paintable rubber sealant to smooth the transition. Then I applied several coats of bed liner until the surface matched. The brand of the mat was BIG MAT, bought it used at a garage sale and not sure how to get another. Attached are several photos. I hope this helps, Pat

Posted on: 2013/12/8 19:49

|

|||

|

||||

|

Re: need a close up photo of a 39 120 running board

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks Pat. I'll go by the truck place tomorrow and see what they have in stock. I'll also stop by the farm and ranch store, as this looks very close to some stall mats for horses. Great suggestion, and I appreciate the photos.

Posted on: 2013/12/8 23:07

|

|||

|

||||

|

Re: need a close up photo of a 39 120 running board

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks Pat. I'll go by the truck place tomorrow and see what they have in stock. I'll also stop by the farm and ranch store, as this looks very close to some stall mats for horses. Great suggestion, and I appreciate the photos.

Posted on: 2013/12/8 23:07

|

|||

|

||||

|

Re: need a close up photo of a 39 120 running board

|

||||

|---|---|---|---|---|

|

Home away from home

|

No luck at the farm and ranch store. McMaster-Carr makes some 1/8" thick rubber roll matting that has a straight rib on it that I can buy on line. However, I went out this evening to take a closer look at the running boards. I had always assuming that the old rubber was just badly worn. No such luck. The previous owner, in a sadly misguided attempt to fix the missing rubber, spread Bondo over the entire running board and sort of smoothed it out, then painted it black. Using a chisel I was able to remove most of it - sure stuck good to rusty metal! What I have left are the ridges and valleys and about 8 thousand holes where the rubber was attached to the steel. I think I will remove the running boards and take them to the guy who bead blasted my 51 prior to painting. This should take care of the rest of the bondo and rust. Then I can fill the holes and sand them smooth. I'm leaning toward the Dip -It spray rubber technique. This will allow the old steel ridges to show, while any rubber mat I install will probably telegraph the groves in the metal and conflict with the pattern in the rubber.

Pat - what did you do on the surface prep on your boards?

Posted on: 2013/12/9 22:23

|

|||

|

||||

|

Re: need a close up photo of a 39 120 running board

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I found this placefloormatcompany.com/doormats/commercial- ... ed-wide-rib-rubber-runner-mats.html when I was looking for 47 possibilities. It has a wide rib mat that looking at the guys footprint might be close to what you are looking for for your 39.

MMPmetrommp.com/?f=part_list_by_type&Type=Running%20Board%2FFloor%20Mat also has a couple of wide spaced ribs although theirs has a rounded look on the top which may not be suitable.

Posted on: 2013/12/9 22:35

|

|||

|

Howard

|

||||

|

||||

|

Re: need a close up photo of a 39 120 running board

|

||||

|---|---|---|---|---|

|

Home away from home

|

David,

To answer your question about prep, I have two stories, what I did leading to the photos you see and what I originally tried. First, the original plan. The set of boards on my car when I bought it also had some of the rubber left on them, badly cracked, dry and patched with bondo by the previous owner. I chiseled, hammered, ground....to no effect. My buddy suggested using the blue wrench: heat. This worked well, but generated smoke if the rubber became too hot. Once burned, it chipped off cleanly. Yes, rubber vulcanization to metal is an amazing thing. Then basic metal cleaning and repair was to begin. This was about the time I began searching for place that could do the job professionally. Since I could not afford the cost, things were essentially on hold. A while later, I came across a used set of boards from a hot rod, with filled and smoothed upper surfaces. The bottoms of these boards were in great shape, better than the ones I planned to use. More time passed before I decided that I'd leave the smooth tops but rough them up and apply matting to them. The bottoms were media blasted and painted a satin/semi flat black. The matting was glued using 3M material as I mentioned. You'll see in the photos that I cheated with the fender welt between fenders and boards since I could not nicely roll the mat around the ends as the original vulcanization achieved. I believe the rubberized coatings would give a great finish if the underlying metal is in good condition and well prepped. With a few coats, I expect the 8 thousand holes will fill and smooth. I've seen Packard and other cars done with both the truck bed or rubberized coatings and considered them very respectable, especially in light of the high premium for the concourse finish, vulcanized alternatives. Pat Good Luck, Pat

Posted on: 2013/12/10 21:01

|

|||

|

||||

(56.03 KB)

(56.03 KB)