|

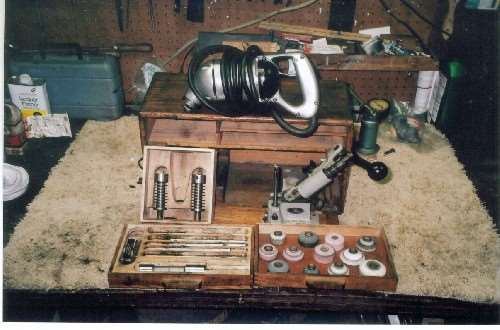

Valve grinding tools

|

||||

|---|---|---|---|---|

|

Home away from home

|

Working on my 115c. While driving out one of the valve guides, I made a very rookie mistake, and boogered up a valve seat. It now has a small dent in it. After much colorful language, I wised up and put a block of wood over the rest of the valve seats when I was driving out the valve guides. A few were quite stubborn.

Does anyone have, or know someone who would have, a lead on tools like those shown here: youtube.com/watch?v=QDEJ3coQa14 I am going to try to fix the damaged seat using one of my old exhaust valves, rough valve grinding compound and a hand lapping tool; calling local machine shops is my backup plan. But, I am assuming that most local shops won't have tools like these or experience working on a flathead engine, so I wanted to try here as well. Thanks, as always!

Posted on: 2014/10/24 21:18

|

|||

|

1937 120 1092 - Original survivor for driving and continued preservation. Project blog / Registry

1937 115 1082 - Total basket case, partial restoration, sold Hershey 2015 Project blog / Registry |

||||

|

||||

|

Re: Vavlve grinding tools

|

||||

|---|---|---|---|---|

|

Home away from home

|

Owen, thanks for the info! I'll look around locally, and if I really get in a bind, I'll send you a PM. Here is a picture of the damage- what are you thoughts? I am guessing about 0.010 or 0.015", but I haven't tried to measure it yet. Yes, that is a hammer mark. Yes, I am a big dummy. Public service announcement- when you are whaling on a valve guide driver, put wood over the rest of the valve seats!

Posted on: 2014/10/26 15:49

|

|||

|

1937 120 1092 - Original survivor for driving and continued preservation. Project blog / Registry

1937 115 1082 - Total basket case, partial restoration, sold Hershey 2015 Project blog / Registry |

||||

|

||||

|

Re: Vavlve grinding tools

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Thanks for the photo. It's hard to estimate the depth of the damage to the seat from the photo but it looks pretty severe. You could grind away with valve lapping compound for a half a lifetime and doubt you'd get it cleaned up. Just a guess from what I see but I think the only "good" cure is to have a hardened valve seat installed and if you do that, you might just as well go ahead and do all the exhaust valve seats.

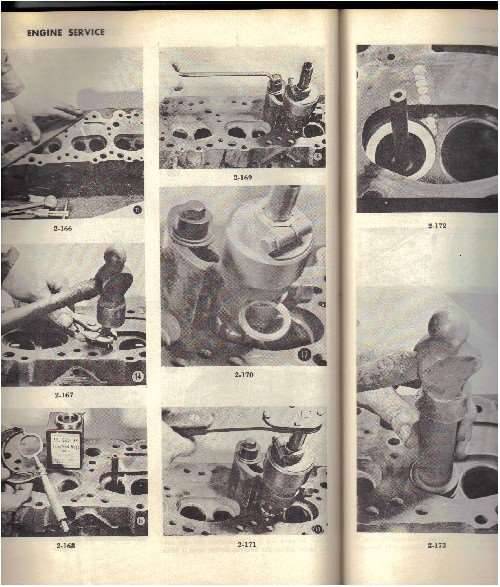

But if you come across a valve seat grinding tool set you might give it a try - I've never done one that bad. What will happen is as you grind the seat down to the base of the damage the seat will widen very much - perhaps to as much as nearly the full face of the valve and typically you want a seat width of about 3/32, more or less. Then you'll need a 30 degree (or in any case less than the seat angle) stone to narrow the seat which will involve the removal of A LOT of metal - hopefully not so much as to make the installation of a hardened seat problematic should your attempt fail. As the seat lowers from grinding, the valve stem will of course sit lower in the block so as mentioned before, you may have to grind some off the end of the stem to get back into range of the lifter - no big deal there. Also as the valve sits lower, the spring tension will be decreased; for the low rpms most collector cars are driven that may not be a problem but should you be successful in restoring the seat, you probably should consider installing shims to the spring in an amount equal to the amount the seat was dropped. The only other possibility I see is to locate one of those tools for cutting the block with the engine in the car to accept a valve seat insert but as I said I've searched without success for one of those tools (it was a Chrysler special tool) for 40 years and never seen one. I wish I could be more optimistic, and best of luck with the outcome no matter which route it takes; keep us posted and let me know if I can be of any further help. PS - I'm assuming it's an exhaust valve seat? PPS - here's an excerpt from an old Glenn's which shows the tool and process for relief cutting and inserting a valve seat insert with the block in the car, so at least you know what the tool looks like. In the particular example the seat was inserted after a "stitching" repair of a cracked block across a valve seat which isn't relevant to your case but the process is the same. I've looked thru the Packard special tools catalogs, ditto for the Kent-Moore special tools and not seen the seat cutter listed so apparently it was not in wide use.

Posted on: 2014/10/27 8:39

|

|||

|

||||

|

Re: Valve grinding tools

|

||||

|---|---|---|---|---|

|

Home away from home

|

Owen- thanks so much for the info! I'll call around tomorrow and see if I can get quotes on getting hardened valve seats installed. Any thoughts on how much that service normally runs? I suppose a 3 angle valve job would be in order at the same time.

I used a piece of Play-Doh (I have a 2 year old) to make an impression of the damage. It is 0.021" deep, so my guess is too deep to grind out, but that is just a guess.

Posted on: 2014/10/27 20:37

|

|||

|

1937 120 1092 - Original survivor for driving and continued preservation. Project blog / Registry

1937 115 1082 - Total basket case, partial restoration, sold Hershey 2015 Project blog / Registry |

||||

|

||||

|

Re: Valve grinding tools

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

It is 0.021" deep, so my guess is too deep to grind out, but that is just a guess.

As I mentioned I've never had to contend with grinding a valve seat with that kind of damage, but I suspect your guess is correct. The biggest expense in having valve seat inserts installed is going to be labor for removing/reinstalling the engine block unless you're fortunate in finding a local engine rebuilder who has the tool to cut the block for the insert with the engine in the car. Sorry to hear about your problem and your advice about using something to shield the block while you pound on the guides is worthy of emphasis.

Posted on: 2014/10/28 9:22

|

|||

|

||||

|

Re: Valve grinding tools

|

||||

|---|---|---|---|---|

|

Home away from home

|

Ken,

I just had my 374 done. The cost of cutting out and replacing with Hardened seats is $108, Add in the valve job to lap them to the new seats $95. $200 would get ya fixed up. .022 is way to deep to grind out.

Posted on: 2014/10/28 9:50

|

|||

|

[url=https://packardinfo.com/xoops/html/modules/

|

||||

|

||||

|

Re: Valve grinding tools

|

||||

|---|---|---|---|---|

|

Home away from home

|

I found a local machine shop here, I'll call tomorrow to get a price and go from there.

Thanks for all of the information! I will have the three angle valve job done at the same time- no reason to hand lap if I have to get new valve seats. Not too bad to pull the engine- I already have the entire front clip off. I will have to buy, borrow, or rent a cherry picker. I was planning on buying one some time, just not tomorrow. The small silver lining is that it will make the touchup painting on the block I need to do that much easier. I'll update once I have the machine work done.

Posted on: 2014/10/28 20:59

|

|||

|

1937 120 1092 - Original survivor for driving and continued preservation. Project blog / Registry

1937 115 1082 - Total basket case, partial restoration, sold Hershey 2015 Project blog / Registry |

||||

|

||||

|

Re: Valve grinding tools

|

||||

|---|---|---|---|---|

|

Home away from home

|

I believe lapping the valves to the seats is still required even after both have been reground.

(o{}o)

Posted on: 2014/10/28 21:51

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

|

Re: Valve grinding tools

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Lapping is not recommended if both the seats and valves have been machine-refinished - this provides a more precise and smoother surface than you get with compound and hand lapping.

You could do a check however to make sure they seat well; a series of radial lines with a soft pencil across the valve face and then rotate the valve back a forth perhaps 1/4 turn in each direction under thumb pressure - then remove and check that all the lines are evenly broken.

Posted on: 2014/10/28 22:45

|

|||

|

||||

(104.70 KB)

(104.70 KB)