|

Re: Transmission shifting rod set up 48 Packard

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

If the adjustment range is really far out and there is a chance of parts having been swapped, I would wonder if the rods are correct for the engine, trans, and model combination. There are 4 different sets of long rods used on the 22-23 series and 3 different sets of turnbuckle ends. Wear in the bushings and on the rod ends is also a big issue with the rods and levers which can affect how things mate up. Make sure all the connections are relatively tight.

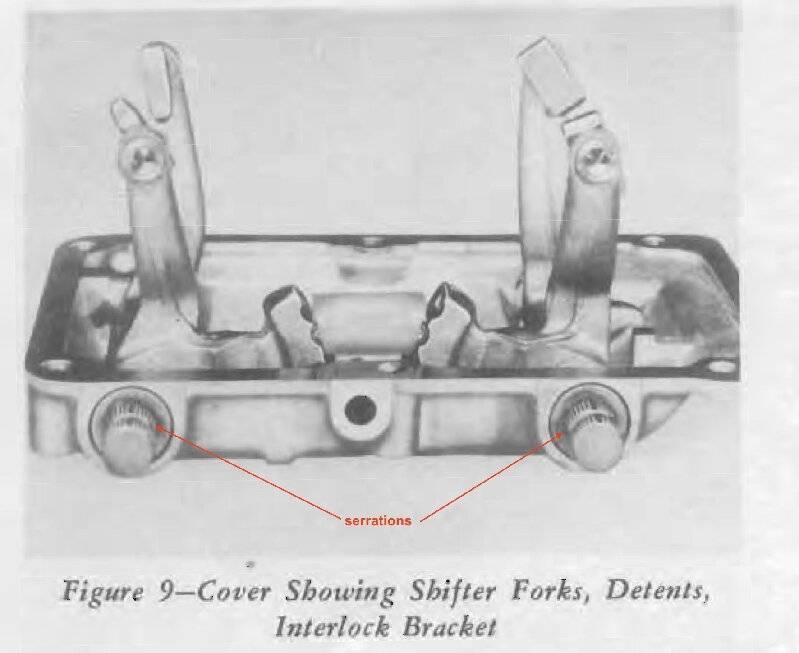

If those are the original components and in good condition, then it might be worth a shot to see if you can move the levers a degree or so. I don't remember if the lever clamp holes are also serrated but there are serrations on the shafts at the transmission where the levers mount. If the levers have matching serrations the combination may be too coarse to get a very fine adjustment. My 47 wound up with the operators lever neutral position a couple of degrees above horizontal before the turnbuckle rods slipped in.

Posted on: 2022/6/21 10:13

|

|||

|

Howard

|

||||

|

||||

|

Re: Transmission shifting rod set up 48 Packard

|

||||

|---|---|---|---|---|

|

Home away from home

|

The shifter shafts and arms have double serrations so you can only put the arm on the shaft one way. You can see that at the 12 o'clock position in Howard's photo.

Posted on: 2022/6/21 11:45

|

|||

|

||||

|

Re: Transmission shifting rod set up 48 Packard

|

||||

|---|---|---|---|---|

|

Home away from home

|

Okay, I have the trans set up and in neutral, also the shifting rods set with the turnbuckles set in neutral. But the gear shift in neutral and is not moving at all.

I can shift the transmission by hand at the transmission and at the shifting rods but not from the column.

Posted on: 2022/6/24 14:33

|

|||

|

||||

|

Re: Transmission shifting rod set up 48 Packard

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

After making sure you removed the setting pin from the two levers at the base of the steering column, the first thing I would suggest is verify the two shift levers are free on the shift tube and very easy to independently rotate. Remove the short turnbuckle rods you have struggled to insert. With the operator lever relaxed, the upper 2-3 lever is selected so the lower R-1 lever is just sitting and should be free and rotate easily on the shift tube. Reach down and verify this is the case. Have someone pull the operator lever back against the spring to select the R-1 lever and repeat the test on the upper 2-3 lever. It too should be very free to rotate on the shift tube.

Lack of lubrication on the upper 2-3 lever is a well known issue and rust and corrosion can get between the lever and shift tube to do a job. If it is sticking and tries to move the least amount at the same time the lower R-1 lever is selected, the rod geometry will try to move its corresponding lever at the trans first. If the interlock is working properly, the least movement of one lever will almost instantly lock out the other. If the one you want to move is already locked out and the other is still trying to move, both will be affected.

Posted on: 2022/6/24 14:50

|

|||

|

Howard

|

||||

|

||||

|

Re: Transmission shifting rod set up 48 Packard

|

||||

|---|---|---|---|---|

|

Home away from home

|

Do the 2 levers at the base of the steering column move seperately. I found the oiling hole and added oil.

They move together. The centering pin is out. The thin matching line is visible on my picture.

Posted on: 2022/6/27 18:44

|

|||

|

||||

|

Re: Transmission shifting rod set up 48 Packard

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

The levers must move easily and separately. If they do not the transmission interlock will come into play and block the shift mechanism.

When the operators lever is in the forward relaxed position the upper 2-3 lever is selected and will not move without the operators lever also moving. The lower R-1 lever is not selected so will be free to rotate if you grab hold and try to move it. To test the upper lever, the operators lever must be pulled toward the driver and held against the spring. That selects the lower R-1 lever and leaves the 2-3 lever free to move. It is much easier to grab and test the levers by hand if the rest of the linkage is disconnected so you are only trying to move the levers and not the entire linkage and transmission. The oil hole will allow the oil to get inside the tube to lubricate the inner rod and some can run down and then out the tongue selector slot and catch the lower R-1 lever. Unless a few drops stays on the outside of the hole and runs down the tube it does nothing to lubricate the upper lever. To get any lube in that upper area, if there is any play between the lever and upper washer those two can be slightly forced apart and drops of oil applied on the outside of the tube directly at the top of the lever so it can run down in the space between the lever and tube. If it is really tight then it might be necessary to temporarily remove the upper clip to gain a bit more space so enough oil can be applied to run down and actually do some good. Here is a tube that did not get lubricated and shows the rust and corrosion formed where the levers should rotate. The 2-3 lever was absolutely frozen to the shift tube which, when force was applied to try and shift the locked up transmission, the pot metal operators lever connection was broken. After removal of the tube assembly and partial disassembly of that area it still took quite a bit of heat and force to free the lever and quite a bit of work to get the shaft even at a minimal amount of polish.

Posted on: 2022/6/27 19:41

|

|||

|

Howard

|

||||

|

||||

shaft ends.jpg (110.87 KB)

shaft ends.jpg (110.87 KB)

CC318DDB-F241-44BB-B49F-D70F683501B4.jpeg (252.04 KB)

CC318DDB-F241-44BB-B49F-D70F683501B4.jpeg (252.04 KB)