|

Torsion level question

|

||||

|---|---|---|---|---|

|

Home away from home

|

My 56 Exec's TL system has never worked properly since I have owned her. Upon purchase I received pics of the car being loaded onto the transport and the TL system was working then. I have since found out that I have an unconventional 2wo-switch manual override setup. I can use these switches only after turning the on-off switch to off (otherwise the fuse blows). The automatic TL function is not working because I can load-up the back seat and the rear end drops and doesn't recover. This is with the on-off switch on. The front end seems to be 'stuck' in it's lowest position (riding on the rubber suspension 'bumpers'). No matter which manual switch I use, the rear end either raises or lowers and the front end doesn't move.

What can cause this knid of problem? I have noticed that there are some wire splices around the compensator and motor. I have ordered a new TL manual override switch kit from Max Merritt and will put the system back to it's original state and then install the correct switch. Thanks for your thots, Bob

Posted on: 2010/11/22 10:04

|

|||

|

Bob

IF EVERYTHING IS COMING YOUR WAY ... - - - - - - - - - - - - - - - - - - - - - - - - YOU'RE IN THE WRONG LANE! '56 Executive Touring Sedan |

||||

|

||||

|

Re: Torsion level question

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I agree with Joel. Make sure the wiring is identical to the diagrams the way the factory installed it. After that works satisfactorily, install the switch from Max. One of the requirements is the system must be properly lubricated. Be patient and lube all the fittings associated with the suspension. The lube chart is available on this site.

Doublecheck the wiring at the limit switches is not broken as that has frequently been a problem. Come back and let us know how you're doing.

Posted on: 2010/11/22 10:24

|

|||

|

||||

|

Re: Torsion level question

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

No matter which manual switch I use, the rear end either raises or lowers and the front end doesn't move.

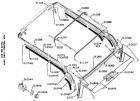

Maybe I'm missing something here, but if the rear end goes up and down, that's how the system works. The movement of the front end, up and down, only happens in sympathy with the rear end going down and up, kind of like a pivot around the center of weight. Perhaps part of your problem is excessive friction in the front end pivot for the torsion bars - there are a couple of grease fittings there for some needle bearings - perhaps they've been long ignored. To work properly the system has to be essentially friction-free.

Posted on: 2010/11/22 10:34

|

|||

|

||||

|

Re: Torsion level question

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

In addition to what every one has said, it is also possible your bars are loaded pretty well with the accessories and can't lift much anymore. If so, that might be the reason the car is riding the bumpers. When the car is level, how high is it off the ground at the mid point? Senior Packard models are around 10" and while I don't have a spec on the Clipper chassis based models, assume around the same.

Check the front load links and count the number of lines to see which ones you are using. If the shorter ones, then adjustable links or ones with more length possibly will help. Each line additional (there is a max length allowed) is supposed to raise about 3/8". TB55-1 gives some basic info.

Posted on: 2010/11/22 10:50

|

|||

|

Howard

|

||||

|

||||

|

Re: Torsion level question

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

I am guilty of ignoring the grease fittings. One thing that happened after letting the car down from the jack-stands. I heard a 'bang' as the front end was resting on the right wheel (the left jack-stand was still there). A small, squareish rubber bushing with a hole came shooting out from under the car. I think it might be a stabilizer bar bushing.

Posted on: 2010/11/22 10:54

|

|||

|

Bob

IF EVERYTHING IS COMING YOUR WAY ... - - - - - - - - - - - - - - - - - - - - - - - - YOU'RE IN THE WRONG LANE! '56 Executive Touring Sedan |

||||

|

||||

|

Re: Torsion level question

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

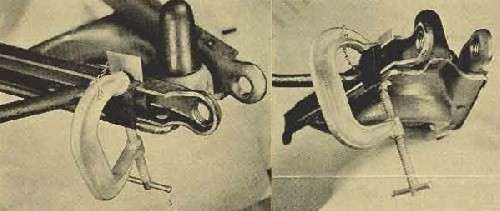

Very possible and even in normal circumstances, those wear. Repros are available and might be a good idea to change them anyway. I would recommend you fabricate some kind of tool along the Packard linespackardinfo.com/xoops/html/downloads/SC/SC-VOL25NO7.pdf to remove and replace instead of prying with a screwdriver. The clips are hardened, so brittle & sometimes a P.I.A. to remove and particularly to replace with new rubber. The little tabs break off easily if mistreated.

Posted on: 2010/11/22 11:02

|

|||

|

Howard

|

||||

|

||||

|

Re: Torsion level question

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

In addition to the above excellent advice, I would ad that the timing box on the frame sends a ground to the solenoids located inside the driver's side fender well. Get the system working the way it was originally intended, automatically and you won't need the manual switch except for rare occasions like trailoring or steep driveways. The TL system suffers from a lot of blue-splice butchering, followed very closely by the pushbutton system. Everyone knows more than the engineers who designed the system.

Posted on: 2010/11/22 11:07

|

|||

|

||||

|

Re: Torsion level question

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Are these tools still available to buy? Quote:

To 'bugger-up' a system like that is such a waste of one's time and effort to repair, not to mention the monitary cost. I hope I don't run into any other 'hack' jobs, because this seemed to be such a 'honest' car (I think it still is). Bob

Posted on: 2010/11/22 11:41

|

|||

|

Bob

IF EVERYTHING IS COMING YOUR WAY ... - - - - - - - - - - - - - - - - - - - - - - - - YOU'RE IN THE WRONG LANE! '56 Executive Touring Sedan |

||||

|

||||

|

Re: Torsion level question

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I don't know if the tools were ever reproduced but they are very simple.. Look at the top of the lower arm to see the spacing between the two upper retainer tabs. That piece is just sheet steel or aluminum approx 1/8 thick -- just thick and wide (maybe 2" or so) enough to fit in the slots behind the tab and has two protruding legs of approx 1/4" long--one into each slot. The other part is a regular C clamp. Large enough to fit as shown in the picture. You can take the fixed end to a grinder and grind a slight groove or contour into it so it won't roll off the upper rounded corner of retainer.

Posted on: 2010/11/22 11:58

|

|||

|

Howard

|

||||

|

||||

(7.92 KB)

(7.92 KB)