|

Re: Bob Aller Oil Pump Rebuild

|

||||

|---|---|---|---|---|

|

Home away from home

|

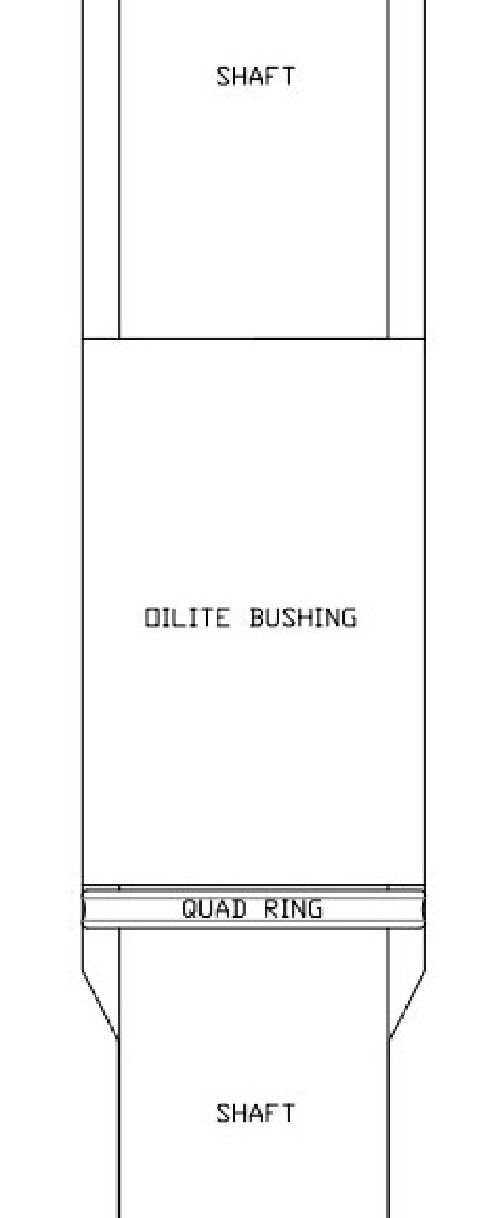

I was thinking today about this situation and I think the combination of adding an Oilite bushing and a quad-ring to the non-bearing section of the pump could provide some improvement. Of course this would be in addition to Ross's modification.

This just uses a basic 1/2 x 5/8 x 1 Oilite bushing and a 1/2 x 5/8 x 1/16 fluoroelastomer quad ring. Not sure how much it would help to be honest, but it doesn't seem like it would hurt. Before you ask, the quad ring is rated for both oil/chemicals and up to 400 degrees F. A fancier way to do it would be to use a ball bearing and a 12X19X5 HMS5 V1 shaft seal though I think that it overkill, and it also requires both overboring the non-bearing section of the bore slightly, to two different bores (18mm for the bearing and 19mm for the seal above it) and also turning down the shaft to 12mm (from 12.7). The drawing is not necessarily to scale on the vertical axis.

Posted on: 2024/3/28 15:23

|

|||

|

1955 400 | Registry | Project Blog

1955 Clipper Deluxe | Registry | Project Blog 1955 Clipper Super Panama | Registry Email (Parts/service inquiries only, please. Post all questions on the forum.) service@ultramatic.info |

||||

|

||||

|

Re: Bob Aller Oil Pump Rebuild

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Regarding ball bearings: probably because having a pair of ball bearings would not seal against oil pressure and having only one is somewhat redundant. Also cost. I don't doubt that cast iron is a tougher surface than oilite but there are other places (the generator) that oilite is used with a long life. Where I want to place a bushing here there should be nearly no radial load on it anyway... it's mainly to align the shaft with the seal, since the shaft is worn. And to retain the seal. Thanks for your thoughts on it.

Posted on: 2024/3/28 15:56

|

|||

|

1955 400 | Registry | Project Blog

1955 Clipper Deluxe | Registry | Project Blog 1955 Clipper Super Panama | Registry Email (Parts/service inquiries only, please. Post all questions on the forum.) service@ultramatic.info |

||||

|

||||

|

Re: Bob Aller Oil Pump Rebuild

|

||||

|---|---|---|---|---|

|

Home away from home

|

By the way I did go ahead and order some bushings and quad rings from Grainger to test this out. What I'm afraid of is having to bore with a 5/8 drill to get the bushing to fit, which I don't have. The somewhat rough surface will not be a problem for the seal.

I measured the ID and got .6222, the bushing is supposed to be .6250, so it might press fit, but probably not. Get some ice water...

Posted on: 2024/3/28 19:24

|

|||

|

1955 400 | Registry | Project Blog

1955 Clipper Deluxe | Registry | Project Blog 1955 Clipper Super Panama | Registry Email (Parts/service inquiries only, please. Post all questions on the forum.) service@ultramatic.info |

||||

|

||||

|

Re: Bob Aller Oil Pump Rebuild

|

||||

|---|---|---|---|---|

|

Home away from home

|

Trying to do precision machine work with a drill press and a twist drill has not been possible in my experience. What you're trying to do requires a mill and a reamer.

BTW, the generator uses an oilite bushing because it's not pressure fed. The oilite will survive with wick oiling where the cast iron requires pressure. jack vines

Posted on: 2024/3/29 10:49

|

|||

|

||||

|

Re: Bob Aller Oil Pump Rebuild

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks Jack, I appreciate your feedback, though my experience differs on point 1. With a piloted hole and proper technique you can get very good tolerances just with a drill press and bit. For example I have used a 6.3mm (.252) drill in the past to drill sliding fit ¼" dowel pin holes. Obviously yes if you need like 0.0005 diametral tolerance you'll need more precise tools.

Anyway, it turned out that boring the hole was not needed as even though the hole was about .6222 and the bushing .6272, I was able to just tap the bushing in with a ball peen, using the shaft to pilot it. The installed bushing ID is about .497 which is great for the maing shaft dia. Then I just deburred with a drill bit, not by passing the bit, but just holding it at an angle and using the cutting edges to deburr. The quad ring is easily installed or removed with a pick once the bushing is installed. Reminder: this is a spare oil pump, not the one off my engine. When I pull that I will inspect it the same way and also try to test the performance of it somehow. Still thinking of the easiest/best way to do that. Want to try as-is, then with this bushing mod, then add Ross's mod on top of that. Here are pictures showing the install. The second picture shows the approximate location of the installed parts.

Posted on: 2024/3/30 7:34

|

|||

|

1955 400 | Registry | Project Blog

1955 Clipper Deluxe | Registry | Project Blog 1955 Clipper Super Panama | Registry Email (Parts/service inquiries only, please. Post all questions on the forum.) service@ultramatic.info |

||||

|

||||

|

Re: Bob Aller Oil Pump Rebuild

|

||||

|---|---|---|---|---|

|

Home away from home

|

Nicely done. That will work well if the shaft and pump body are not too worn.

jack vines

Posted on: 2024/3/30 9:52

|

|||

|

||||