|

Re: Urgent Online Advice Needed; re, King Pins..

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Typically on many cars for decades, the pin is probably tapered and only drives out one way. You do not drill them out. Look at the diameters at the ends to see which is the large end and which is the small, and of course drive it towards the larger end. Some models use a threaded nut on the small end to be removed first.

Posted on: 2009/8/23 14:49

|

|||

|

||||

|

Re: Urgent Online Advice Needed; re, King Pins..

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Yes, some tapered locking pins use nuts to help draw them tight, but not all.

Just a year ago, we had an old IHC grain truck referred to the shop I was working at, and it had tapered pins (with no nuts) that just wouldn't budge. This one had TWO locks per king pin - one from each direction, IIRC. Seemed like all the punch and hammer method did was swell the locking pin tighter - guessing it was rust bound. However, heating with a torch didn't seem to help, and we weren't equipped with a dedicated press for such work. We resorted to drilling them out as described above. Even after that, it took a lot of heat from a torch to get the king pins to loosen up, but once they started responding to the message relayed from the sledgehammer, they practically fell out. Turns out the king pins were very badly corroded in the area covered by the axle.

Posted on: 2009/8/23 15:24

|

|||

|

||||

|

Re: Urgent Online Advice Needed; re, King Pins..

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Irish -

Are you saying you got the knuckle off WITHOUT removing the king pin? That's contrary to how I've done it, but I've only worked on king pin suspensions on postwar vehicles.

Posted on: 2009/8/23 15:33

|

|||

|

||||

|

Re: Urgent Online Advice Needed; re, King Pins..

|

||||

|---|---|---|---|---|

|

Home away from home

|

It seems the only way to get the knuckle off is to lift it off the axle end over the in situ pin.

Have one side done, this is not a one day job!

Posted on: 2009/8/24 8:06

|

|||

|

||||

|

Re: Urgent Online Advice Needed; re, King Pins..

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Have one side done, this is not a one day job!

Chilton's Flat Rate Manual calls for 5.6 hours labor for the job.

Posted on: 2009/8/24 8:17

|

|||

|

||||

|

Re: Urgent Online Advice Needed; re, King Pins..

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Hmm, I always had to first drive the king pin out, through the bottom, to remove the knuckle, but - again - I've only worked on postwar examples. These prewar cars must be quite different.

What did it take to finally get the locking pin (what you call a "wedge") out?

Posted on: 2009/8/24 8:37

|

|||

|

||||

|

Re: Urgent Online Advice Needed; re, King Pins..

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

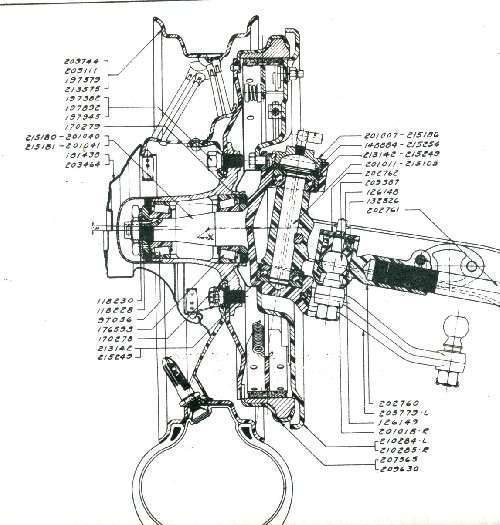

Brian - enlarge and then take a good look at the picture I posted from the parts manual. It looks to me like the "plug" at the top where the oil filler plug is located and which ends at the top with a hex for a wrench, unscrews from the knuckle after which the top bearing can be removed. Then it appears that the knuckle can just drop down and off.

I feel a bit sorry for Irish, all that work just for prior negligence in lubrication. Looking again at the picture you can see the small passages for the oil flow to the upper and lower bearings and that, plus the oil reservoir at the top show why they wanted the pins oiled with heavy oil and not grease. Common error in maintaining these cars, and ditto for the universal joints.

Posted on: 2009/8/24 8:45

|

|||

|

||||

|

Re: Urgent Online Advice Needed; re, King Pins..

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

OK, I could not see the threads until I clicked on the pic and then zoomed in.

Looks like there's enough space between the top end of the axle and the knuckle for a punch to help walk the bearing out, This is completely different than the later kings pin set-ups that I've worked on. Now, with the bearing removed, I envision that you could drop the knuckle down to clear the lower end of the king pin and slip it completely off. Interesting approach. Thanx for the clarification, Dave. When it comes to lubrication of king pins, regardless of the style, I have seen too many cases where an owner was penny-wise but pound-foolish.

Posted on: 2009/8/24 9:05

|

|||

|

||||

|

Re: Urgent Online Advice Needed; re, King Pins..

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Brian - glad you see what I see, looks very straight-forward. Here's another view from the parts book which may also be useful. I did go out and check mine just now, the tapered retaining pin is simply that, no threaded end and nut on the small end, just drive out from the smaller diameter end towards the larger. Hopefully Irish avoided the earlier advice of someone who suggested drilling the pin out. The OEM pins have lateral "flutes" on them which compress when you drive it in and hold it in place.

Posted on: 2009/8/24 11:24

|

|||

|

||||

(137.45 KB)

(137.45 KB)