|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Home away from home

|

HH,

You are right, Safety first.

Posted on: 2015/5/3 21:43

|

|||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Home away from home

|

OK, load arms part II

I tried to re-seat the left side, rear load arms tonight. As the jack got pressure on the load arm (but the chain is not at full tension yet) the frame raises a little. That small amount of lift almost un-seated the right side rear, load arm. It actually did come partially unseated but I was able to get it corrected without any problem. Now how do I keep it that way while I work on the driers side?

Posted on: 2015/5/6 19:15

|

|||

|

Stewart Ballard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Can't quite understand why one side is affecting the other but any chance a C clamp could be installed. If there is enough room for the clamp below that keeper bar across the center of stirrup, it could be between the load arm and bottom of stirrup to keep the seat and arm tight. You might even be able to use a block or wedge between that keeper bar and the load arm to keep them seated.

If not enough room, install a large clamp at an angle between the inside stirrup corner and the load arm top to keep it pulled in and arm down. That way might take two clamps -- the large one at an angle and the other can be smaller. Place that small one across the load arm so the large clamp couldn't slide on the arm toward the stirrup and possibly come off.

Posted on: 2015/5/6 19:38

|

|||

|

Howard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Home away from home

|

As I raise the frame the right side load arm is raising also and the rear support arms is staying in place. They are kind of moving opposite directions from one another.

Could this be because I have the Watts link and shocks disconnected at the moment?

Posted on: 2015/5/6 20:20

|

|||

|

Stewart Ballard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I guess I'm more confused than usual. Not understanding what you are pushing on that would be raising the frame or why. I thought you were just raising the load arm high enough to swing the stirrup into position. The purpose of the chain around the jack is to keep the frame from raising in relation to the load arm.

If the frame is raising and there is nothing to do to prevent it then the anchors in the floor and a chain around the frame might be an option -- as long as you still use the chain around the jack while raising the arm. I would not trust anchors alone to keep everything on the floor with the massive force that arm has stored up.

Posted on: 2015/5/7 10:39

|

|||

|

Howard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Home away from home

|

Stewart,

I don't have an answer other than to test what you suggested. Attach the linkage and shocks. Can you tell if the rear axle is moving, or the frame is twisting at all? Use the same setup that you used on the other side and see what that does. Go slow to see if that will work. I am looking for otheir items, but there was a set of prints that the Packard Club reproduced about loading the bars. But I remember something about having 4" of space between the axle and the frame. This document may not help at all, but if someone else has it, they might be able tell us what it said. I could be remembering wrong too!

Posted on: 2015/5/8 10:11

|

|||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

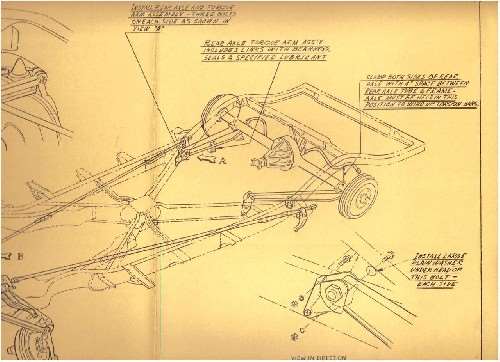

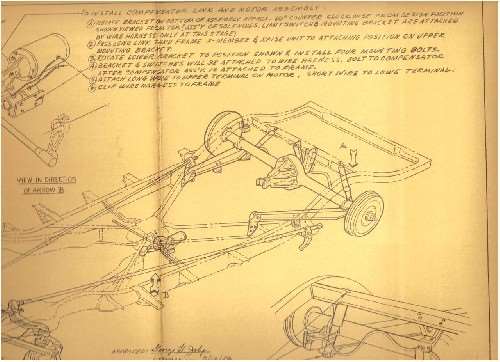

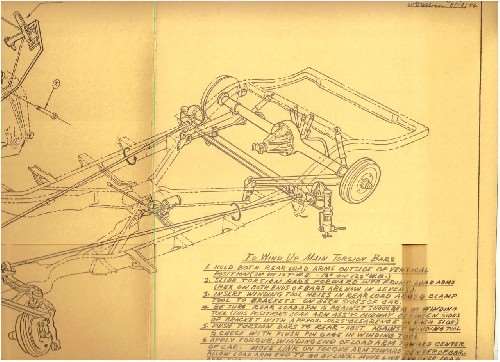

Those factory drawings of the TL assembly that were reprinted by PAC are still available for a few bucks. I have a copy somewhere and will look for it later in the day and scan anything that looks useful. But for installation at the rear is utilizes the factory pneumatic torsion bar winding jig so I'm not sure how much help it might be.

PS - For Station Two the PAC publication does say to clamp both sides of the rear axle so the axle tubes are 4 inches from the frame and hold them in position while winding the bars, but again that's winding them with the factory power bar winder. PPS - partial scans of Stations 2,3 and 4 of 5. Sorry, the images were two large for my scanner so they're just partial views.

Posted on: 2015/5/8 10:17

|

|||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Home away from home

|

I took off yesterday and went to St Louis to watch the Cards and the Cubs play.

Will be back in the shop tonight or tomorrow morning. I'll try to explain this better. The passenger's side load arm is re-seated as explained earlier. The watts link and shocks are disconnected because I thought that would make it easier to re-seat the load arms. Disconnecting these was actually suggested to me in an earlier post. That's how it all setting right now. Now, I set up the jack and the chain on the left side just like I did before. When I start to jack up the load arm the whole frame raises up maybe an inch to inch and a half as the tension is taken out of the chain. Since the support arms are floating (due to the watts link and shock being disconnected) they do not rise that inch or more along with the frame. It remains setting on the jack stand. That inch of separation that I am creating is causing the right side load arm to come un-seated every time. Maybe I should go ahead and un-seat the right side. Reconnect the watts link and shocks. Then re-seat the load arms. This way when the frame raises again with the jack the whole rear axle and supports will rise with it and everything will stay where it belongs. Suggestions.

Posted on: 2015/5/8 13:16

|

|||

|

Stewart Ballard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Home away from home

|

Stewart,

Reconnecting the rear load arms to the stirrup seats is "easy peasy". My Panther frame is in pretty much the same state as your 55 400: Body off, engine & trans out, S-bars and shocks disconnected. To reseat the load arm tip with the mating stirrup part, just jack up one side with a floor jack. No restraining chains are required. As the frame on one side comes up, it will align the load arm end with the stirrup seat. At that point, just push it on (maybe a tap from a small sledge is required). Once you get it more or less seated, wire the two together as shown in the following pictures. Then repeat on the other side. Works every time for me.   I used cut down coat hanger wire. The stirrup always comes off towards the center of the car (away from the load arm pivot), so that is the part that has to be constrained. Of course, once you get body weight back on the frame, just cut the wire off for operation. Craig

Posted on: 2015/5/8 14:46

|

|||

|

Nuke them from orbit, it's the only way to be sure! Ellen Ripley "Aliens"

Time flies like an arrow. Frui |

||||

|

||||

(119.74 KB)

(119.74 KB)