|

Re: Ultramatic Rebuild

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

The timing kit was developed because some drivers did have more desire for speed and did want to shift from low to high when taking off from a stop. Keeping in mind Packards demographic, the Ultramatic was developed for ultimate smoothness and quiet operation so was designed to work in high range all the time. Packard even went to lengths to promote this feature in their advertising by comparing the jolts and noise a person felt in a Packard to those other people had to contend with in a car with transmissions that shifted. With that in mind the Packard was rather sluggish when starting as compared to some of the other automatics of the day which did start in low range and do an automatic shift.

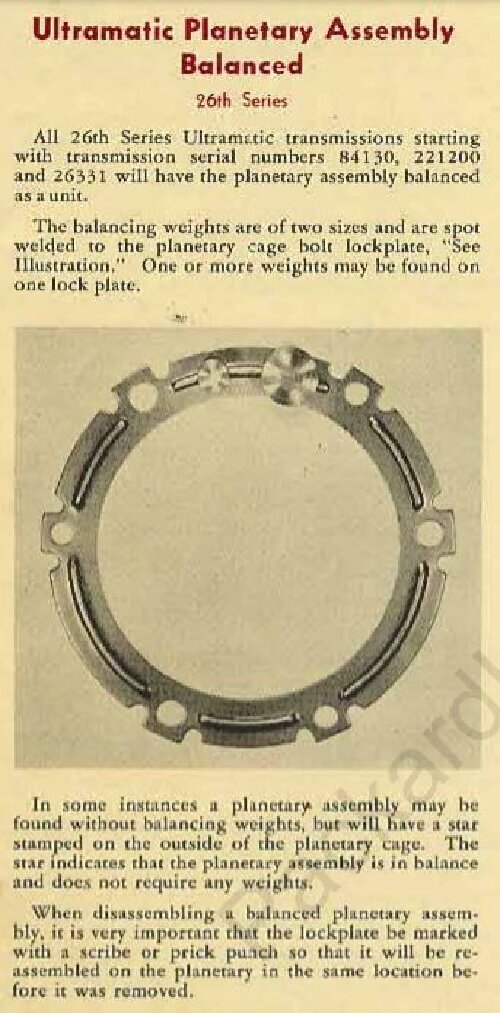

Hydramatic was the comparison transmission with jolts Packard compared itself with but the Hydramatic was also much faster off the line and by 52 or 53 most of the other brand cars had their own automatics which also outperformed the Ultramatic. I guess when a Packard driver who found himself only halfway down the block when his neighbor in a cheaper car was already at the next stoplight complained it finally hit home. Packard found themselves being rather uncompetitive and with a real risk of damage to the transmission or engine with the mistimed shifts, tried to remedy this situation to the extent possible with the existing unit. Hence the timing kit was developed which was better but still not very competeive with other brand automatics. The somewhat rushed 54 gearstart, later named Twin Ultramatic was Packards first unit to be of relatively "modern" construction. Those have a position which works like the old Ultramatic but also have an added position that works like the other competitive units of the day. Unfortunately by 56 better units from other mfgs also came along so it too was surpassed but by then it probably didn't matter. On the balancing issue, the early converters were not balanced as a unit and had weights tacked on each half or at bolt locations. That did change after awhile as the bulletin mentions but even thru 56 it was advised to use a punch and mark each half of the converter so they could be assembled back in the same position. I don't know if there was ever a unit balance done between a converter and flex plate but there might be some indication there was if you find any extra bolted on weights or thick washers. It is still good practice to mark how things were assembled so any wear patterns match up and that might be what they are suggesting.

Posted on: 2024/9/15 12:01

|

|||

|

Howard

|

||||

|

||||

|

Re: Ultramatic Rebuild

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks Howard! Always appreciate your feedback!

Finished removing the transmission from the parts car today. At least I think that's the transmission under all the dirt and oil!   My parts car is stored at the back of this quonset, and people have already put their trailers and boats away for the winter, so I had to slide my transmission on these pieces of plywood about 60 feet to my trailer. I wasn't too worried about the pan, it is pretty beat up! The things we do for our cars!  This transmission rebuild is supposed to be a winter project, but now that I have it out I'm itching to dig into it! Maybe I'll "just" get it cleaned up...............for now.

Posted on: 2024/9/16 1:11

|

|||

|

||||

|

Re: Ultramatic Rebuild

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

While you are working in the trans maybe you could also think about possibilities for adding a longer dipstick. This subject has come up several times over the years when new owners find out what is involved in checking fluid. Most people do not like having to raise the car and go under to check or add fluid. Several threads have touched on the subject and had suggestions but to the best of my knowledge no one has carried any thru to a finish. Destroying a spare cap by putting a hole in the cap to hold the transmission end was one viable solution but some kind of stopper that would push down to be a snug fit inside the fill tube and spare an original cap would probably be better.

Here is one of the threads showing a distinct possibility of using a Lokar universal dipstick. Summit and Jegs also have dipsticks for GM products and possibly one of those could be adapted. If something easily installed and removed should a next owner want to go back to stock could be devised to keep and use the existing fill tube to mount the trans end of a dipstick I think a lot of people would be pleased. I don't have any photos but maybe someone with a gearstart could post a photo showing the engine side location of the 54 dipstick. I believe it comes up somewhere near the starter motor but don't know exactly where it is positioned on the firewall.

Posted on: 2024/9/16 9:08

|

|||

|

Howard

|

||||

|

||||

|

Re: Ultramatic Rebuild

|

||||

|---|---|---|---|---|

|

Home away from home

|

I have been thinking about that!

One thought, as Ross mentions, is that once all the seals are replaced it won't be much of a concern unless you see a puddle of fluid under your car. My current thought is to add a sight glass like this to the pan so it's easy to verify the transmission fluid level and health. Removing that little dipstick and trying to get an accurate reading is not easy, not to mention I'm always concerned about getting dirt in the transmission while doing this.

Posted on: 2024/9/16 9:33

|

|||

|

||||

|

Re: Ultramatic Rebuild

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Sightglass might be an option but unfortunately it would still require someone to go under the car to add fluid. Questions would be if the drainback from the converter when engine is stopped could possibly fill the sightglass and then not clear fully when you wanted to check the level and would you be able to read if accuratedly from a distance or at an angle without the need to go under for a straight on close up look.

Posted on: 2024/9/16 9:44

|

|||

|

Howard

|

||||

|

||||

|

Re: Ultramatic Rebuild

|

||||

|---|---|---|---|---|

|

Home away from home

|

Once seals are replaced having a check, maybe once a year, is all that would be necessary. Gotta go under my car every now and then for servicing anyway.

If the sight glass isn't clearing then I think that would indicate bigger issues, such as contamination. Even looking at a bit of an angle would still provide an accurate reading, more accurate than the dipstick I'm sure. There would be no reason to remove the dipstick unless adding oil from underneath, which is easier to do at the filler on top. The other reason would be for a smell test if there was a concern, such as the oil changing colour, but this too could be done from the filler on top. I may never have to remove that goofy little dipstick again! LOL

Posted on: 2024/9/16 10:00

|

|||

|

||||

|

Re: Ultramatic Rebuild

|

||||

|---|---|---|---|---|

|

Home away from home

|

Sculpted a transmission out of Alberta dirt!

I'm assuming this tag is the date this transmission was assembled? 11-26-52  It's hard to tell in the b/w pictures in the Service Manuals, but would the outside of the transmission for my 53 Cavalier have been painted all battleship grey? Control linkage painted black?

Posted on: 2024/9/17 10:48

|

|||

|

||||

|

Re: Ultramatic Rebuild

|

||||

|---|---|---|---|---|

|

Home away from home

|

Would this be considered normal wear on the reactor shaft? This transmission, as far as I know, has 90,000 miles on it.

Is this an indication of the general condition of the transmission?

Posted on: 2024/9/18 15:39

|

|||

|

||||

|

Re: Ultramatic Rebuild

|

||||

|---|---|---|---|---|

|

Home away from home

|

I have seldom seen a reactor spline that worn. How is the fit of the shaft as it passes through the convertor stub shaft?

Posted on: 2024/9/18 20:21

|

|||

|

||||