|

Re: One Story Assembly Plant What If?

|

||||

|---|---|---|---|---|

|

Home away from home

|

The small window of opportunity becomes obvious, only June to September '53.

The window was even shorter than that, it slammed shut the day the Hydramatic plant in Livonia burned, August 12th. Edgar Kaiser called up GM the next day and asked if they would like to lease part of W-R as they had 1,000,000 sqft free and clear, the space the Air Force C-119 program had occupied. I wonder if EGB could have been organized in such a way to emulate a single story plant in the interim Yes, partly. The complex was long enough that a chassis line could be on the ground floor, with the body line on the second floor so when the body is complete, it's dropped through a hole in the floor to mate with the chassis below. iirc at one time EGB was set up that way. The Ford Highland Park plant was set up that way as well. Getting components and supplies to the upper floors would still be a problem, because the multi-floor design does not lend itself well to the conveyors and fork-lift trucks that were used for material handling post WWII. Once the J-47 contract was gone, that must have freed up space but was it all at Utica? Utica as built, was about 780,000 sqft, about the same as Connor. Packard also bought an existing building on Mt Elliott in Detroit to make forgings for the J-47s, some 325,000 sqft. The thing about defense contracts is the products need to be made in secure locations, not integrated with civilian production. When Kaiser was building C-119s, they had to build a wall inside W-R to keep the C-119 area seperate and secure. I doubt the end of the J-47 program freed up any space at EGB. Christopher touted the duel assembly lines instituted for 200K units; were those still in place, one line could have been converted for complete body assembly and trim, phasing out Connor over a couple of years. When Nance first started at Packard, he asked about bringing bodybuilding in house. The CFO, Grant, said that obtaining the equipment, probably primarily the presses, and installing it in EGB would only make economic sense with a production rate of 200,000 cars/year, more than double what Packard was selling. Besides doing the body building at Conner, Briggs was leasing space at EGB to do additional work on the bodies before handing them over to Packard. Packard was building the front clips, seats, instrument panels and trim and adding them to the bodies before they were dropped on the chassis. This was all going on in the section of the plant south of East Grand. <i>..assembly operational stability was key to putting highly satisfactory cars into customer hands in the critical early sales season.</i> Agreed. Nance was a salesman, not a cost accountant or manufacturing engineer. He was swayed by Grant's estimate that continuing with Conner and EGB as they had would save $8M/yr, while adding final assembly at Conner would save $12M/yr. Ray Powers should have gotten on top of the conference room table and jumped up and down saying that the space at Conner was not adequate and the disruption of workflow would create inefficiencies. There is an Executive at the Gilmore Museum near Kalamazoo. It looks like a survivor, rather than a restoration. The hood doesn't fit, there is a 1/4" gap in the trim by the driver's side headlight, there are huge gaps in the trim at the top of the door windows. And the 56s were supposed to be put together better than the 55s? It's a beautiful car, until you get a close look at it.

Posted on: 2014/6/8 23:47

|

|||

|

||||

|

Re: One Story Assembly Plant What If?

|

||||

|---|---|---|---|---|

|

Home away from home

|

PS: I'll have more comments later on the Studebaker off the Packard Clipper platform....like the idea!

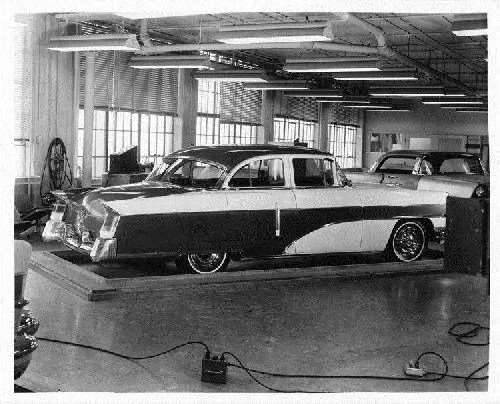

Here are some clays that Packard did for the 56 Clipper, the intent being to establish the Clipper as a stand alone brand, which was resisted by dealers and customers. The front does not have the Packard grill shape, like the production 56 Clipper had. I think it has a bit of a Mercury look to it. The rear view, especially the driver's side taillight has a very strong 56 Chrysler look to it. The dash looks like it was proposed for the Patrician, but it looks a lot cheaper than the dash the Patrician, and Clipper received for 55/56, so I'd say that qualifies it for a Studebaker. The only thing I'm not sure about would be the timing of the Studebaker buyout. I'm after three things from Studie: the parts inventory as that would produce immediate cash flow from supporting Studies already on the road, the brands and trademarks, and the dealers. If I bought Studie as a going concern, I could do it with stock, which is how Packard did it. Downside, I'd also aquire Studie's debt, $7.5M, which isn't really that bad compared to what AMC had, and Studie's unfunded pension liability. If I waited until Studie went bankrupt, which, the way they were going, could have been 55, I could duck the debt and pension liability. But then, I would have to pay cash for the parts, brands and trademarks. And buying these assets in liquidation would probably take a year. Could the dealers hang on that long?

Posted on: 2014/6/9 0:21

|

|||

|

||||

|

Re: One Story Assembly Plant What If?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Restating the obvious, from the couch of the Monday Morning Quarterback, the failures of both the PMCC and S-P have been well documented by both Ward and Kimes. Blame cannot rest on one human but is better spread onto a series of circumstances within and outside of Packard's control. With the slow ending of Defense contracts, the deaths of two key players (George Mason and Walter Briggs), and the lack of a solid audit of Studebaker as a partner, bad things kept on coming. More universally, the auto industry was over-producing and dealers were flooded with cars that the public was bored with. Interest rates and mandated high down payments kept more sales stillborn. You had to pay more for a Packard than a competitive Lincoln, Chrysler or Cadillac and buyers did not see the value in it the way they did before 1953.

Having a Big Four competitor in a company that sold Packards, Hudsons, Nashes and Studebaker (cars and trucks) might have been a wonderful thing. But having a former GM President as Secretary of Defense only ended up making General Motors a stronger company while Ford and Chrysler had to scramble for the leftover customers. Perhaps the brightest spot in these sad series of developments was the resurgence of the compact Rambler that made the one year 1958s of GM look extravagant while making George Romney look prophetic. From what I gather, my 1956 sat unsold on a Virginia dealer's lot for almost six months, even after a massive price reduction from $6204 to $4200. A third off and the orphan probably needed another discount to find a home! Fifty eight years later, I like to think she has one.

Posted on: 2014/6/9 7:40

|

|||

|

||||

|

Re: One Story Assembly Plant What If?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Hi Steve203

Thanks for your enlightening responses to each of my curiosities about plant configurations so quickly. The timeframe for Nance to act was so brief it probably passed before he even considered it as an option. Configuring EGB as nearly as possible to a single story or partial bi-story operation to gain whatever efficiencies would have been a good plan. Some modifications to EGB would have been required for material handling; ramps and conveyors, even running to the outside if necessary. From CFO Grants analysis that the cost of presses, etc. re-installation could only be warranted on a 200K/unit production, perhaps retaining stamping operations at Connor for the time being but phasing in complete body jigging, welding through final trim to EGB on a second floor body line above the chassis line would have been the solution. It's something of a work-around but still utilizes the main plant more fully, rather than creates more unused space. If instituting such a plan produced better quality 1955 models for immediate delivery at introduction time, I wish Powers would have championed it as an alternative to total assembly Connor move. It seems as if internal costs savings were the focus of their decisions, not how potentially disastrous such a disruptive move could be on the cars the customer received. On the Studebaker buyout: Studebaker had been losing market segment ground every year since 1950 but still had some assets worth savaging. It's dealer network was broader but populated with many small, weak dealers, though could have given Packard better coverage when dualed. The inefficiencies and labor problems at South Bend were nearly insurmountable without a bankruptcy. That course presented many dangers as the mid-'50's buyer was very wary of purchasing any make that might become an orphan. If Packard had decided to get tangled-up with South Bend, they'd have had to do something of a quick acquisition then speedily integrated production at Detroit. Retaining the Chippewa plant to build trucks and Hawks for '56 on would have keep the dealers happy while giving them new larger Commanders and Presidents, more acceptable cars than the "flaccid anatomy sedans" they had been pushing. Though its hard to imagine how they might have come to the idea without market distress, the '53 sedan tooling eventually was the basis for the Lark series. If management had decided to pursue the compact car course earlier as an adjunct to the full-sized offerings , perhaps a Lark style crash program for '56-'57 might have been mounted. At any rate, Studebaker and its South Bend operations presented a situation that would have had to be approached with extreme caution......like handling a poisonous snake! Steve

Posted on: 2014/6/9 10:06

|

|||

|

||||

|

Re: One Story Assembly Plant What If?

|

||||

|---|---|---|---|---|

|

Home away from home

|

From what I gather, my 1956 sat unsold on a Virginia dealer's lot for almost six months, even after a massive price reduction from $6204 to $4200.

Not surprised. Various sources state that, at the time EGB was closed, half of the 56s that had been produced were still unsold. But having a former GM President as Secretary of Defense only ended up making General Motors a stronger company Yup. Ward goes into that in some detail. Apparently, Wilson's funneling business to GM, at the expense of the other automakers, was so blatant that the media, including Drew Pearson, was attacking Wilson. One of the unknowns is that, had Packard sold the J-47 contract to Curtiss-Wright, or Continental CAE, would it have been cut the way it was when Packard was profiting from it? Neither C-W or CAE appear to have had any problem landing defense contracts. In 55, just as the Packard J-47 contract was being closed out, CAE landed a contract to produce jet engines used in an Air Force trainer. CAE leased the government owned plant in Toledo that Packard had used for the Merlin program and it's late 40s jet development. CAE produced those engines for 20 years, and in the 80s was producing cruise missle engines there. Interest rates and mandated high down payments kept more sales stillborn. True, the Fed raising interest rates impacted all consumer spending. Packard, not having an in house finance company, like GMAC, could not subsidize it's customer's and dealer's financing as GM could. S-P's fractured Board of Directors wasn't helping it's case though. Following the AMC merger, the Hudson plant was quickly closed and production consolidated in Kenosha. Not only did S-P keep both plants operating, in spite of both plants producing below their break even levels, Ward points out that they couldn't even agree to consolidate testing at one proving ground and sell the other.

Posted on: 2014/6/9 10:29

|

|||

|

||||

|

Re: One Story Assembly Plant What If?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Some modifications to EGB would have been required for material handling; ramps and conveyors, even running to the outside if necessary.

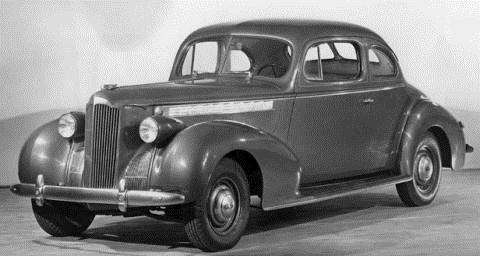

I'm not sure that would be feasible. Besides the narrow footprint of some of those buildings, I would not want to go driving down a ramp in a fork lift with a load of engine blocks. As best I can tell, the Packard plant did not even have the material handling solution that other old multi-story plants had. The photo shows the interior of one of the Studebaker buildings. Each department on the upper floors has a balcony overlooking this central core. Railroad cars bring material in and an overhead crane lifts material to the balcony of the appropriate department. I have seen interior photos that show Ford Highland Park used this same system. EGB doesn't appear to have enough room for the railroad tracks to make the turn to go between building wings to use this system. Attach file:  (36.09 KB) (36.09 KB)

Posted on: 2014/6/9 10:54

|

|||

|

||||

|

Re: One Story Assembly Plant What If?

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Many 54 Packards also sat on dealer's lots for months awaiting sale at distressed prices; 54 was a bad year for the industry and for Packard another factor may have been anticipation of the "new" V8 models. A friend bought a 54 Cavalier that sat on the lot of McBride in Ridgewood NJ for over half a year and was finally sold well into 1955.

Another insight into the Studebaker-Packard acquisition fiasco (if you can locate them) and the details contained in the legal proceedings of the stockholder lawsuits by Packard stockholders that went on for a decade or more.

Posted on: 2014/6/9 10:56

|

|||

|

||||

|

Re: One Story Assembly Plant What If?

|

||||

|---|---|---|---|---|

|

Home away from home

|

<i>...perhaps retaining stamping operations at Connor for the time being but phasing in complete body jigging, welding through final trim to EGB on a second floor body line above the chassis line would have been the solution. It's something of a work-around but still utilizes the main plant more fully, rather than creates more unused space.</i>

That phased transition to bringing bodybuilding into EGB is, according to Ward, what Nance wanted to do. Briggs being sold forced Nance to make other plans on short notice. As for the unused space at EGB from moving final assembly to Conner, reportedly the Board decided to sell all the facilities south of East Grand in the spring of 56, just retaining the offices and shops north of the street. It's dealer network was broader but populated with many small, weak dealers, though could have given Packard better coverage when dualed. Ward noted that some Packard dealers were so poor they didn't even have a Packard demonstrator. In 58, we relocated from Dearborn to Kalamazoo. According to the dealer directory on this site, the address of the Kalamazoo Packard dealer was in a somewhat sketchy neighborhood. I remember the Studebaker dealer however, a reasonably nice building in a prime location on Michigan Ave, right across the street from the Rambler dealer. A more agressive dualing of dealerships would probably have been an upgrade for Packard in that town. Retaining the Chippewa plant to build trucks and Hawks for '56 on would have keep the dealers happy while giving them new larger Commanders and Presidents, The problem with retaining Chippewa Ave is Packard would still have to deal with local 5. I suspect that Chippewa was also dependant on the main South Bend complex for stampings and power train, so you would have to buy more facilities to support Chippewa, or create more logistics problems supplying the plant from Detroit. If Packard really wanted any Studebaker facility, I would have gone for Hamilton, Ontario. A reasonably modern plant, with a breakeven, iirc, of 30,000/yr. Hamilton appears to have created it's own local supply chain for everything but powertrain, which was shipped from South Bend. The only thing I would have done with that plant, with that small capacity, would be move the truck line in. The truck line introduces another problem, what to do about powertrain? A short stroke V8 with a torque peak of some 2500rpm isn't really the thing to have. After the AMC merger, Hudson producton was consolidated in Kenosha, but the Hudson engine plant in Detroit was kept operating so the Kenosha built Hudson Hornet could still be offered with the 308. A Studebaker truck with a Hudson "big six"? Stump pulling torque at 1800rpm? Then make up a different name, like the Transtar name that Studie started using in 56, and have AMC distribute them as well as Studebaker, as neither Nash or Hudson built trucks at that time? Then there is the local 5 issue. At that time, it was legal for a solvent company to shut a division and stiff the pensioners. Studebaker's pension fund was severely underfunded because it had only been established around 1950, and it immediately vested benefits for the large portion of the workforce that had been with Studebaker for 30-40 years. When Studie closed South Bend in 63, they distributed the pension fund assets as far as they went, and the other ex-employees were out of luck, even though Studebaker Corporation was a solvent, contnuing company. This led to the establishment of the PBGC some 10 years later. Less well known was that Packard's pension fund was also underfunded. The Packard and Studebaker pension funds had never been merged, so when EGB was closed, those employees were stiffed the same way South Bend workers were a few years later. When Kaiser bailed out of W-R, it stiffed it's employees as well, though, being a much newer company, did not have the large numbers of people with decades of service who thought they had vested pension benefits. <i>......like handling a poisonous snake!</i> or, as someone said "like making love to a porcupine"

Posted on: 2014/6/9 11:55

|

|||

|

||||

|

Re: One Story Assembly Plant What If?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Once again, it was not Kimes. It was George Hamlin and Dwight Heinmuller who wrote that section of the Automobile Quarterly book edited by Beverly Kimes. This is not to take away from the monumental job she did putting all those individually authored chapters together. (o{}o)

Posted on: 2014/6/9 12:01

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||