|

Re: One Story Assembly Plant What If?

|

||||

|---|---|---|---|---|

|

Home away from home

|

I think we are all in agreement here. The AQ book on Packard's history is often called the Kimes book, and this is understandable. Just trying to shine the spot light on the often forgotten writers.

(o{}o)

Posted on: 2014/6/9 17:16

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

|

Re: One Story Assembly Plant What If?

|

||||

|---|---|---|---|---|

|

Home away from home

|

There is such a thing as brand stagnation. A few products like Coke and Marlboro can hang in there because they are cheap junk. However the way of buyers can be very fickle. The situation today is that nobody is building a car intended to get you where you want to go. Supposedly people don't buy cars based on reliability. If that is the case do they deserve anything but junk?

The disappearance of Pontiac, Plymouth, Mercury, Oldsmobile, and AMC sort of blows up a lot of the Packard situation. If that doesn't then the GM bankruptcy certainly does. Cadillac had dealers operating out of gas stations in the 30's so Packard's little soda fountain operations were not unique. What was different for Cadillac was that GM decided to invest in Cadillac and make it work. Today, Cadillac doesn't serve a purpose either. Nor does Lincoln. When you look at how much capital Packard had access to it still boils down to the amortization of the Packard plant and ultimate liquidation. If the 110 wasn't able to pay for new investment where was the company to go anyway?

Posted on: 2014/6/9 20:30

|

|||

|

||||

|

Re: One Story Assembly Plant What If?

|

||||

|---|---|---|---|---|

|

Home away from home

|

If the 110 wasn't able to pay for new investment where was the company to go anyway?

Lack of reinvestment is a recurring theme with failed auto companies. Studebaker's bankruptcy in 33 is partly laid on Albert Erskine's decision to keep paying stock dividends, even when the company had to borrow to cover the payout. Studebaker was also paying out dividends after the war, while the newest of the buildings in the main South Bend complex dated from the 20s, and some dated to their pre 1900 horse and buggy days. Packard also was paying dividends while it kept repurposing and adding on to obsolete buildings. I remember an article in Fortune in the late 60s, when AMC had a brush with insolvency, that blamed Romney's paying out dividends instead of investing in modern plant and equipment to reduce the company's uncompetitive cost structure. In comparison, when Ford's production process and capacity needs rendered the 6 year old Piquette plant obsolete, he didn't try to adopt it or add on to it. He packed up, moved to Highland Park, and built and entire new, state of the art plant. When Ford's production process and capacity needs rendered the then 18 year old Highland Park plant obsolete, he moved to Dearborn and built another new, state of the art plant, the Rouge.

Posted on: 2014/6/9 21:34

|

|||

|

||||

|

Re: One Story Assembly Plant What If?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Hi Steve203

"like making love to a porcupine" What a prefect descriptions of everything to do with Studebaker all the way around! You are right that as long as any manufacturing operations were kept at South Bend, the UAW Local 5 would have been an ongoing problem. Had Packard waited for the inevitable Studebaker bankruptcy before buying them out, it would have been in a much better position to clear away much of the baggage the made doing business there such a problem. Keeping the customer faith that Studebakers were still going to be produced, not become an orphan, would have been the trick. On the stampings, I recall reading that Studebaker relied on Budd to do a good deal of that work, as well as some in-house. Moving the Studebaker truck production to Hamilton would have been one escape route, though engine availability still problematic. I've considered whether with Packard completely in control after dissolving the Studebaker board and aggressively integrating operation, if IH might have been contracted to badge-engineer/restyle their trucks as Studebakers. Though Studebaker trucks were well accepted in rural areas, they still held a small portion of the total truck market. The Hawk line had the potential to tap the emerging sport- personal luxury coupe segment that Ford would soon exploit with the four passenger Thunderbird. Producing those at Hamilton might have been an option. With a degree of chassis refinement, fitted with Packard V8's and Ultramatics, they might have carved a nice niche volume and become an image builder as well. Of the plant situation analysis, the main thing that comes through is how much the way cars were built changed in the thirty years from the '20's to the '50's. The strongest players didn't hold onto old plants when newer layouts developed, didn't keep retrofitting obsolete plants. One supposes it was just intracted ways of doing business that kept the smaller independents from moving with the times, as in "its worked up to now, why change?" Plowing profits back into the business might not have been as good for the share price in the short term, but was beneficial long term. Steve

Posted on: 2014/6/10 12:32

|

|||

|

||||

|

Re: One Story Assembly Plant What If?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Had Packard waited for the inevitable Studebaker bankruptcy before buying them out...Keeping the customer faith that Studebakers were still going to be produced, not become an orphan, would have been the trick.

Keeping the customer base, and keeping the dealers on board. Buying the Studebaker assets in liquidation would have taken months, maybe a year. How could a dealer survive that long without new cars to sell, and could he even obtain replacement parts for his existing customers? Additionally, buying assets in liquidation requires cash, which Packard was short of. And Grant was telling Nance Packard was "on a path to bankruptcy" so the pressure to do "something" fast was extreme. On the other hand, doing a stock swap for Studebaker as a going concern, as Packard did, does not require cash, but has another problem. As Ward spelled it out, because Studebaker was a larger company, the stock swap worked out so the Studebaker stockholders had a controlling interest. Any attempt by Packard to rationalize the operation by shutting South Bend would have been blocked by the Studebaker interests. The competing Studie and Packard interests on the Board of Directors were so deadlocked they couldn't even agree to consolidate testing at one proving ground and sell the other one. My plan to produce the senior Studebaker models as decontented Clippers would never have gotten past that Board. A prickly situation indeed. On the stampings, I recall reading that Studebaker relied on Budd to do a good deal of that work, as well as some in-house. I know that Budd made the dies for the 53s, the ones with the front fenders that didn't fit. I have seen plans of the South Bend complex and there is a building labeled "stamping" in the middle, close to the head of the assembly line buildings. Moving the Studebaker truck production to Hamilton would have been one escape route, While keeping the truck line has crossed my mind, I'm not sure it would be worthwhile. When the R series was introduced in 48 it was very popular and Studie had a larger share of the truck market than they had of the car market. But they didn't make any additional investment in the line. They changed the grill a couple times, went to a one piece windshield and enlarged the window in the back of the cab, but that was it. By the mid 50s, it's design with the projecting fenders and a narrow cab was looking obsolete. Dodge had widened their cab in 48. Chevy did a dramatic restyle in 55 that made everything else look ancient. The Hawk line had the potential to tap the emerging sport- personal luxury coupe segment True, but the Hawk depended on the volume Studies for everything under the skin. I would have doubts of the economics of continuing production of those parts for such a low volume model, let alone developing the platform. Plowing profits back into the business might not have been as good for the share price in the short term, but was beneficial long term. Yup. Chrysler was also guilty of hanging on to obsolete plants. They hung on to Dodge Main until the early 80s. Probably Henry Ford was able to keep walking away from plants and building from scratch because he didn't have stockholders. I can just see a CEO at a stockholder's meeting saying "I'm going to walk away from the millions we invested in this plant 20 years ago, and drop tens of millions on a new plant." Ford could get away with it because it was all coming out of his own pocket. Speaking of Packard buildings. The only modern buildings at EGB were built for the Merlin program 22 and 84. 84 was cut back to the tune of about 100,000 sq feet when the freeway was cut through. I was wondering when the freeway route was set, to see if there was some chance that the freeway could have been rerouted to keep 84 intact. What I found was that a freeway running along Harper had been proposed in the 20s. The route was laid out in February 1941. At that time, there was probably nothing at the north end of EGB but the remains of the old test track that was at the north end of the complex in the 20s. So, it appears that 22 and 84 were built knowing they were encroching on the freeway right of way. The freeway was nudged a few feet to the north and the ditch narrowed to clear 22, but probably all concerned knew 84 was going to get chopped when it was built. That's probably why nothing important was put in 84 after the war. It was just used as a warehouse.

Posted on: 2014/6/10 17:09

|

|||

|

||||

|

Re: One Story Assembly Plant What If?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Since looking over the Packard side of the proposition, I have been looking at the Kaiser side, and got a surprise.

We have been working on the assumption that Willow Run had a significant stamping capacity. It did not. I was reading "Kaiser-Frazer, The Last Onslaught on Detroit" and noticed a diagram of the plant layout after it was reorganized to accommodate C-119 production. I noticed how small ths area designated as the stamping plant was, and how large the area designated "stamping storage" was. I figured there were only two reasons for having a lot of stampings in inventory: either they would set up the presses for a couple of parts and run off a couple week's supply, then change the dies and run off a couple week's supply of different parts, or they were still outsourcing many stampings. They were outsourcing. In 50, Kaiser wanted to bring more stamping in house, but they didn't bring it into W-R. Kaiser built a stamping plant in Shadyside Ohio, equipping it with a mix of presses from government wartime stockpiles, and presses moved from W-R. In 52-53, the big presses that were producing the Kaiser floorpans and firewalls, among other parts, were in Shadyside. Shadyside stayed open until 57, supplying Kaiser construction after it moved to Toledo, then shipping to IKA until that company could find local stamping plants to support it. W-R had a body assembly area, paint booths and ovens, but an insignificant stamping capacity by June 53. The plant had 1,000,000 sqft of free and clear space, where the C-119 line had been, in the high bay area of the plant, which could take as large a press as you could find. Problem is, Walter Grant's numbers said buying presses would not be cost effective unless production exceeded 200,000/yr. How much are we talking about? In "Last Onslaught" there were comments about presses costing $600,000 each. Then there is the cost to excavate below the floor of the plant and install footings to support the presses. How many presses to make everything in house? In a 1939 film about the Nash Milwaukee body plant, they mention that plant having 185 presses. So even after coughing up $26M+ for W-R, Packard would still be outsourcing stampings. As Hudson production on Jefferson ended with the 54 model year, their body plant on Conner should have been available, but apparently when Packard approched AMC about supplying bodies, AMC was quoting producting and shipping from Milwaukee, which was prohibitively expensive. The Hudson body plant was sold to Cadillac in 56, and Caddy used it until Poletown opened. So stamping supply would be a choice of Budd, if they had capacity available in the heat of the Chevy/Ford overproduction price war, or renting Conner from Chrysler. Even if Nance and Co had thought about jumping on W-R in July 53, they would have rejected it as it still would not, in spite of the cost, solve their impending body supply problem.

Posted on: 2014/6/21 19:13

|

|||

|

||||

|

Re: One Story Assembly Plant What If?

|

||||

|---|---|---|---|---|

|

Home away from home

|

I have been to the BMW Munich plant four times over the past 15 years, but only in the last trip did I take an evening tour that included their vast stamping operation. Treated sheet steel coils come in one end and stamped parts go out to the robot-tended assembly areas and other German plants producing other models. From memory, there are only four huge presses, each four or five stories tall. Across from them are stacks of dies, ready for use and moved by automated overhead cranes. Parts, big and small are made in batches, probably enough to last a week or so in production. Then the dies are changed and new stampings are made. The change-over process may involve one or two humans who mainly watch things move in and out of the presses while the cranes and die movers do their jobs robotically. A die change can take 10-20 minutes, in and out, with one guy to oversee the operation. Imagine how labor intensive auto stamping must have been at the Nash factory in 1939 or Briggs producing metal for Packard, Hudson, Chrysler and who knows what other companies.

Even at the Munich plant, the noise and vibration was significant enough to cause relocation of apartments and houses at least two or three blocks away. Only on the night tours, when things are relatively quiet would the public be admitted. The night quiet hours were negotiated with local authorities so that those residents, three or four blocks distant, could have some peaceful rest. Visitors to the BMW Museum, Welt and Olympic Park apparently don't notice the vibration from the stamping being done a half mile away. I've been near Ford's Woodside stamping plant, modern as it is, but still out in Nowhere, south of Dearborn. I could hear nothing disturbing. But the noise and commotion that must have gone on in the 1940s and 50s when our cars were being made, must have been significant to the plant's nearby neighbors. But then again, a noisy plant meant people were making money by making cars. There was probably no complaining by the EPA-like authorities for matters involving noise, smells or industrial pollution. Times have changed, workers are much fewer but safer, and the cars with real character have gone away, except for the collectors who appreciate what went into the making of them and the sacrifices made by those who made them.

Posted on: 2014/6/21 22:43

|

|||

|

||||

|

Re: One Story Assembly Plant What If?

|

||||

|---|---|---|---|---|

|

Home away from home

|

I have been to the BMW Munich plant four times over the past 15 years,

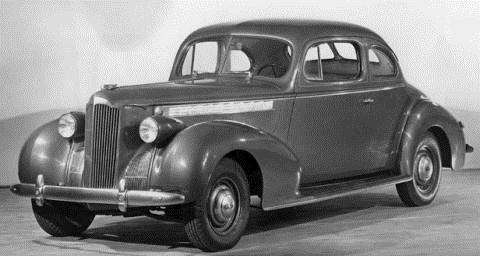

Fisher body opened a stamping plant in Kalamazoo in 65 or 66. The plant had an open house, and my 12 year old self got a good look at an old school stamping operation. iirc, each stamping line had 5 or 6 presses. The man at the first press fed cut sheets down a ramp into the press. After that, sometimes people, sometimes a prehistoric robot arm, would take the piece out of the press and drop it on a conveyor to the next press in the line. Each subsequent press would trim the piece or make the impression from the previous press deeper. The guides pointed with pride to the safety feature in those pre OSHA days: the trigger for each press had two buttons a couple feet apart, so the operator had to use both hands to trip the thing, to make sure he didn't have a hand in the press. At the end of the line, the stampings were nested in crates for shipment. The nearest assembly plant would have been Olds in Lansing. I don't recall the place being excessively noisy, but I was so absorbed in watching how they did things the noise may not have penetrated....and the plant floor was wood blocks, just like EGB had. The pic is of Budd in Detroit just before it closed down. Just about as I remember Fisher Body in Kazoo: 6 presses in a row.

Posted on: 2014/6/22 0:18

|

|||

|

||||

|

Re: One Story Assembly Plant What If?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Maybe Packard should have stayed in Ohio.

Today Michigan is nothing but corrupt government and roads that are worse than Africa. One road has a sign "minimum speed 55 mph". I get a kick out of that. As if putting up a sign means the road is safe. One four letter word company used to beat workers with baseball bats. Today the descendants of that degeneracy are still making work in Michigan a rotten experience. So why keep the business in Michigan anyway? The weather, roads, and government are better almost everywhere else. Next comes senior management. Those people don't know anything about cars, only how to devalue people. Consider how poorly they treat Mexicans. Those decisions are being made by MBA's who think they are entitled to financial welfare from the poor. If it wasn't for the UAW (a pretty sad situation in its own) they would still be hitting people with baseball bats. Hopefully one day south of the border will riot.

Posted on: 2014/6/22 7:24

|

|||

|

||||

(35.86 KB)

(35.86 KB)