|

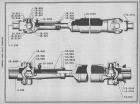

Re: 34 DRAG LINK Adj.

|

||||

|---|---|---|---|---|

|

Home away from home

|

Dear Barry:

The drag link has threaded screws which are turned against the ball socket. The tie rod ends use shims. The junior series manual has some instructions along the lines of "tighten until bottomed and back off 1/4 to 1/2 turn". However, the senior cars used stiffer springs and don't bottom very easily. As the cars age the drag link may need to run a little tighter to prevent shimmy. Before you do anything see if you can have the wheels road force balanced. When the cars were new they steered with ease because everything was solid and in balance. Make sure your spring u-bolts are tight as well. Worn shackle pins and what not will cause loose feel, but those wheels throw a lot of weight around.

Posted on: 2013/9/2 19:03

|

|||

|

||||

|

Re: 34 DRAG LINK Adj.

|

||||

|---|---|---|---|---|

|

Home away from home

|

Rev. A - 9/4/13

Tim - Ever do a RATE test on these springs? Have tested 4 so far: 150 @ 7/8 168 179 214 The 150 is what came out without shim. Thinking this is why shims r called out - so u can take a 150 and take it to the 214+ spec. Just hit me what the SHIMs r 4. Adjusting the Drag Link back/forward to align the straight Str Whl with straight Wheels/Tires. Guessing the Shims have nothing to do with sping tension. Im still diging thru my stuff trying to find what the factory said. Found the Factory setting for a '34 in the SERVICE LETTERS. States bottom the spring out and back of 1,1/2 turn. NO listing for spring rate.

Posted on: 2013/9/3 8:15

|

|||

|

||||