|

Re: Solved: Vibration Damper Removal - 1928 5-26

|

||||

|---|---|---|---|---|

|

Quite a regular

|

28Pack526

Sorry I didn't mention that I'm talking to the guy that has the parts tomorrow (Sunday). Hope you can wait until then. easyed

Posted on: 2014/3/30 0:11

|

|||

|

||||

|

Re: Solved: Vibration Damper Removal - 1928 5-26

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Absolutely. Thanks again.

Posted on: 2014/3/30 1:03

|

|||

|

||||

|

Re: Solved: Vibration Damper Removal - 1928 5-26

|

||||

|---|---|---|---|---|

|

Quite a regular

|

28Pack526

Good news. My friend (has 1928 coupe) thinks he has the parts you need. Will see him 11:00 am Monday. Finally figured out how to post the balance of the pictures of my vibration damper. 2693 grease gooves 2694 pulley for side mounted water pump 2695 brass sheet seal between flywheel halves easyed

Posted on: 2014/3/30 16:46

|

|||

|

||||

|

Re: Solved: Vibration Damper Removal - 1928 5-26

|

||||

|---|---|---|---|---|

|

Quite a regular

|

28Pack525

My friend has the two facing parts but unfortunately he had to take his wife to the doctors. Will see him Wednesday at lunch time. He has some other 443 parts that he wants me to make. (I have a machine shop) Actually measured the facing ring thickness. (.125 inches) will edit previous post. easyed

Posted on: 2014/3/31 16:12

|

|||

|

||||

|

Re: Solved: Vibration Damper Removal - 1928 5-26

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

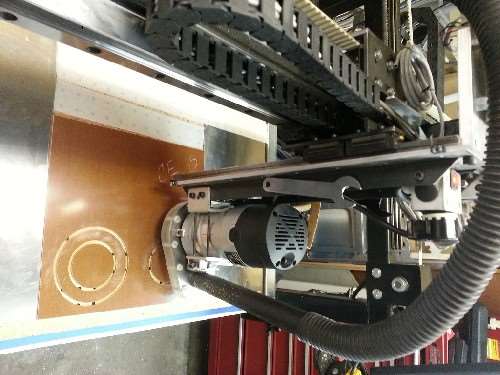

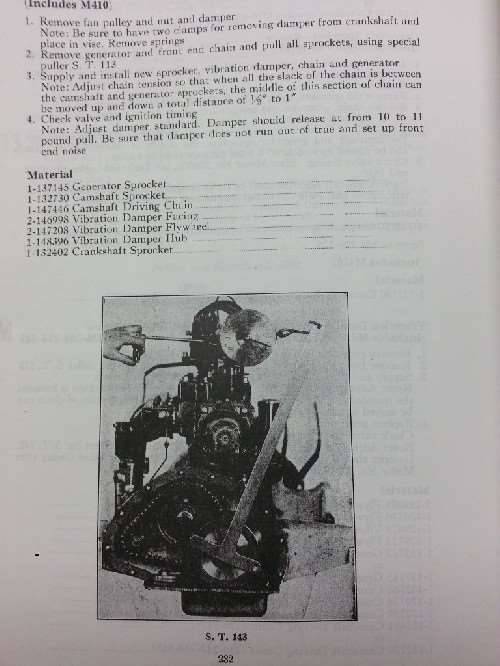

One final post here to wrap up the thread: After contacting every possible parts source I could think of, I determined that the friction discs are unavailable and I'd need to make some for the damper if I wanted it to be functional. I ordered a sheet of Phenolic resin based on easyed's suggestion from Ridout plastics, knocked up some cad drawings of the discs, and borrowed some time on my good friend's CNC machine...

<a href="https://packardinfo.com/xoops/html/uploads/newbb/42808_535226c49905d.jpg"><img src="https://packardinfo.com/xoops/html/uploads/newbb/thumbs/42808_535226c49905d.jpg"></a> <a href="https://packardinfo.com/xoops/html/uploads/newbb/42808_535226f78a6f9.jpg"><img src="https://packardinfo.com/xoops/html/uploads/newbb/thumbs/42808_535226f78a6f9.jpg"></a> From there, it was a trivial affair to install the assembly as follows: hub -> friction disc -> inner flywheel & springs -> outer flywheel -> friction disc -> drive pulley. <a href="https://packardinfo.com/xoops/html/uploads/newbb/42808_5352272978e6f.jpg"><img src="https://packardinfo.com/xoops/html/uploads/newbb/thumbs/42808_5352272978e6f.jpg"></a> <a href="https://packardinfo.com/xoops/html/uploads/newbb/42808_53522735aefd3.jpg"><img src="https://packardinfo.com/xoops/html/uploads/newbb/thumbs/42808_53522735aefd3.jpg"></a> Once installed, however, a question arose that isn't well explained in the service manual (see step 4...). <a href="https://packardinfo.com/xoops/html/uploads/newbb/42808_535227673754a.jpg"><img src="https://packardinfo.com/xoops/html/uploads/newbb/thumbs/42808_535227673754a.jpg"></a> How exactly does one "Adjust damper standard"? From the vague description and included picture of special tool ST 143, I assumed by torquing the drive pulley retaining nut down until the damper released at the prescribed force (10 - 11 lbs). That meant I needed an ST 143... I took some rudimentary measurements of the picture and knocked up the following with a strap wrench, a 1x1, and a digital fish scale. :) <a href="https://packardinfo.com/xoops/html/uploads/newbb/42808_5352278fa2c56.jpg"><img src="https://packardinfo.com/xoops/html/uploads/newbb/thumbs/42808_5352278fa2c56.jpg"></a> It turns out, all of that diligence was ultimately unnecessary. Torqued down completely, my damper releases at ~10.2lbs... right in the prescribed range! <a href="https://packardinfo.com/xoops/html/uploads/newbb/42808_535227b226636.jpg"><img src="https://packardinfo.com/xoops/html/uploads/newbb/thumbs/42808_535227b226636.jpg"></a> <a href="https://packardinfo.com/xoops/html/uploads/newbb/42808_535227c885220.jpg"><img src="https://packardinfo.com/xoops/html/uploads/newbb/thumbs/42808_535227c885220.jpg"></a> That's it! I still have another sheet of phenolic if anyone ever needs a couple of these machined for their damper... Attach file:  (89.22 KB) (89.22 KB)  (52.21 KB) (52.21 KB)  (69.44 KB) (69.44 KB)  (85.96 KB) (85.96 KB)  (78.33 KB) (78.33 KB)  (85.75 KB) (85.75 KB)  (44.85 KB) (44.85 KB)  (34.38 KB) (34.38 KB)

Posted on: 2014/4/19 2:38

|

|||

|

||||

|

Re: Solved: Vibration Damper Removal - 1928 5-26

|

||||

|---|---|---|---|---|

|

Quite a regular

|

28Pack526

I posted you a pm that I had a set of facing discs. Maybe the message did not get to you. Please post the smoothness, etc when you start your engine. Glad to have helped. easyed

Posted on: 2014/4/19 10:40

|

|||

|

||||

|

Re: Solved: Vibration Damper Removal - 1928 5-26

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Shoot, I completely missed that! I had my notification settings wrong and just didn't notice it. Thanks again for checking.

I drove the 5-26 this morning, and the engine feels nice and smooth. If I'm being honest, it's probably all in my head because I know the damper is working now, but it definitely isn't any worse at least ;)

Posted on: 2014/4/19 11:57

|

|||

|

||||

|

Re: Solved: Vibration Damper Removal - 1928 5-26

|

||||

|---|---|---|---|---|

|

Quite a regular

|

28pack526

As I see it the springs separate the two flywheel halves that push against the facings which push against the hubs which are torqued up solid to the crank. This causes the drag noted in service manual. This allows the damper to adjust. This STANDARD is measured by the fixture ST 143. Obviously, your damper assembly, with new facing etc meets this STANDARD. "Adjust Damper Standard" means to me: The damper is allowed to adjust and the standard is measured as follows. No ajustment except changing the facing rings, cleaning etc. To function proper it has to meet this Standard. Let me know if you think I'm off in left field.

Posted on: 2014/4/19 20:07

|

|||

|

||||

|

Re: Solved: Vibration Damper Removal - 1928 5-26

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Easyed, I think you're right on the money with your assessment. The manual's implied meaning makes sense in that context now that I've been through the process.

What I wouldn't give to go back and get some of Packard's factory technician training so that all the similar, short, vague descriptions throughout the service manual didn't leave me scratching my head sometimes :)

Posted on: 2014/4/22 18:12

|

|||

|

||||