|

Re: Valve grinding tools

|

||||

|---|---|---|---|---|

|

Home away from home

|

Have only the one damaged seat replaced. Not all of them.

If the other seats look good then just touch them up with some fine lapping compound by hand. What ever route u take, be sure to inspect the finished lapping or grinding with a good lite source. Shine a lite into the intake and exhaust ports , look aaround the seat of the closed valvee for any lite. Do that before leaving the machine shop. When u get the block home then assemble valves and springs. Turn block on side and pour coal oil into ports and inspect for any significant leakage around the seated valves. Some minor seepage over nite is not a problem. The biggest problem i've ran into over the years, even from well established and well experienced machine shops is often sloppy work that is not obvious without close inspection either using lite or the fuel oil test.

Posted on: 2014/10/29 8:46

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: Valve grinding tools

|

||||

|---|---|---|---|---|

|

Home away from home

|

My major fear would be installing hardened seats on the exhaust. Cutting the block maybe too close to a water jacket. I don't know. Has any research been done on the I8 blocks to determine how much meat is there that can be cut away without fear of the exhaust heat cracking the block due to a small margin of material left after cutting for the insert???

Besides, had the hammer damage never occured then the engine would have went back together with no intention of hardened seats???? One seat probably alot cheaper than having 16.

Posted on: 2014/10/29 10:27

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: Valve grinding tools

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

O_D, I think we are in agreement on this. My comments would have been better stated if I had said that a way to check the contact of the valve with its seat would be to use a light coating of fine lapping compound and briefly lap the valve to its seat and then check to make sure there is contact on both faces and the contacts are in the right locations. Your suggestion to use a series of lines drawn by a lead pencil will do the same thing. Machinist bluing will do the same thing too. It is important to do a final check of the valve to its seat after regrinding. (o{}o)

Posted on: 2014/10/29 10:37

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

|

Re: Valve grinding tools

|

||||

|---|---|---|---|---|

|

Home away from home

|

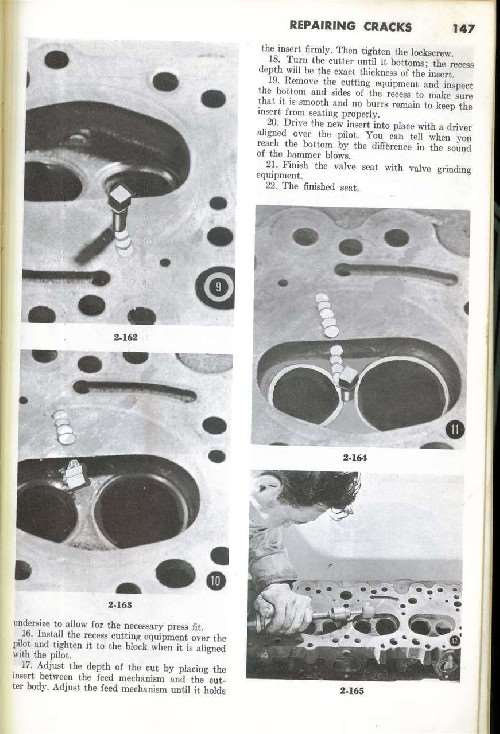

Gents, thanks for all the info. Keith, I was not planning on putting in hardened seats because I have a crack in the block, so I wanted to avoid expensive machine work. It would be about $80 to put in one seat, and $200 to put in all six.

The major downside that I see is that he wants all of the head studs pulled and the crankshaft pulled, which are both jobs that I was planning on not doing. My crank journals did measure out in spec, so I will have the crank polished but not ground. I found a local machine shop with an experienced machinist- he has worked on Packards before and is familiar with the layout. Now I have to decide how much money I want to spend- he can fix the block with cast iron, but it is priced per inch, and I just measured the crack at 4.5"! The repair technique is something I had never heard of- lock and stitch cast iron repair. Of course if I get the cracked fixed, maybe I should just rebuild the whole engine... and this is how a simple ring and valve job gets out of hand. I am thinking I will have him install hardened exhaust valve seats, 3 angle valve job, and evaluate the crack. From there, we'll see. As far as honing- I was planning on doing it myself, but he would only charge $80, and I paid $50 for the tool. How much better would a professional job be over a rookie one. You can't have fast, cheap, and good all at the same time, so it's a good thing I'm not in a hurry!

Posted on: 2014/10/29 20:41

|

|||

|

1937 120 1092 - Original survivor for driving and continued preservation. Project blog / Registry

1937 115 1082 - Total basket case, partial restoration, sold Hershey 2015 Project blog / Registry |

||||

|

||||

|

Re: Valve grinding tools

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

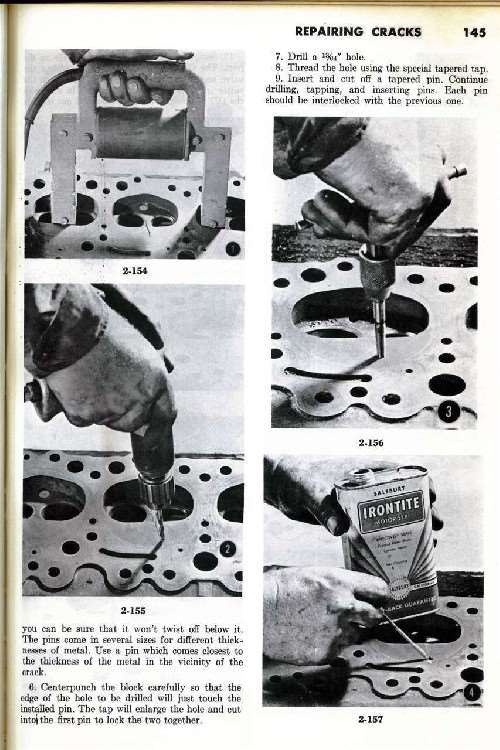

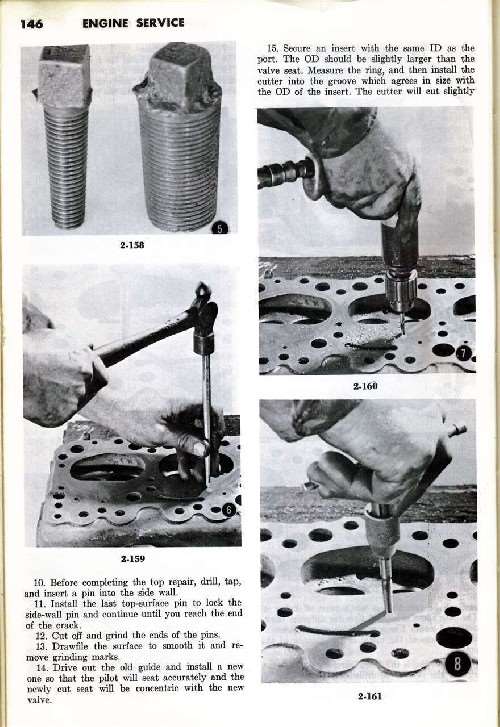

Lock and stitch, or "stitching" method of crack repair, from Glenn's text on engine work. It's a highly successful method though it takes skill and patience.

Posted on: 2014/10/29 22:48

|

|||

|

||||

|

Re: Valve grinding tools

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

I've used the lock-n-Stitch for an 8" (to finally 15") crack in my cooling jacket. Highly recommend it. Since I had no experience with this type repair I got in touch with a tech with the company who was very helpful and informative. A training DVD also came with the order and makes the process look simple - and it was - just took a lot of time and patience. I tried to save some $ and first ordered the incorrect pins for my application and ended up making the crack longer. Finally had to complete it with the correct c-type pins.

Posted on: 2014/11/5 12:34

|

|||

|

1950 Eight Deluxe -2362-

Registry |

||||

|

||||

|

Re: Valve grinding tools

|

||||

|---|---|---|---|---|

|

Home away from home

|

Hey Ken, check with Harbor Freight if there is one close to you. A two ton engine hoist is about $230.harborfreight.com/2-ton-capacity-foldable-shop-crane-69514.html

It is also good to have one of these to tilt the engine. harborfreight.com/3-4-quarter-ton-capacity-heavy-duty-load-leveler-67441.html I bought one several years ago and have used it several times to pull Packard engines, sometimes with the automatic transmission, which pushes the weight to over 1200 pounds. This isn't the one to get if you plan on doing this daily, but it works well for the occasional use. You can take it apart easily and stack it up against a wall. Plus you can print out 20% off coupons - if the unit isn't on sale, you can get some good savings using the coupon. Plus get a free flashlight or multimeter.....

Posted on: 2014/11/6 11:04

|

|||

|

||||

|

Re: Valve grinding tools

|

||||

|---|---|---|---|---|

|

Home away from home

|

David, thanks for the info. There is a harbor freight close to me, but I found one better- a friend with the rusted out remains of a 1966 Mustang unibody on jack stands in his garage. Since he has to weld about 3/4 of the metal back on his car before it's ready to receive an engine again, I have one to borrow for the winter! My garage is already packed to capacity, so I am trying to hold off on the big tools for now.

... Plus I just bought a blasting cabinet from Harbor Freight. :) Sam, thanks for the info and pictures. Looks great! Because of the thickness of the metal, I got the C1a pins. I am a little worried about breaking the tap, but I only bought one, for now. We'll see. It should be a good way to learn patience. Also, Semper Fi!

Posted on: 2014/12/17 22:33

|

|||

|

1937 120 1092 - Original survivor for driving and continued preservation. Project blog / Registry

1937 115 1082 - Total basket case, partial restoration, sold Hershey 2015 Project blog / Registry |

||||

|

||||

(136.31 KB)

(136.31 KB)