|

Re: 21-23 series rubber sill plates.

|

||||

|---|---|---|---|---|

|

Home away from home

|

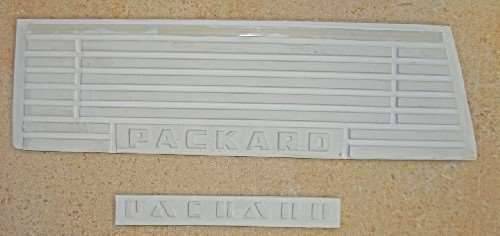

Howard, I don't get on the forum every day but when I saw your thread I took a couple of pics from my 47 Clipper Deluxe. I don't know if the pics help, (might be too large) but here they are. Richie.

Posted on: 2014/11/8 14:35

|

|||

|

||||

|

Re: 21-23 series rubber sill plates.

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

RichieFuller, thanks for the photos. Much appreciated. Those sills are in great shape and show all the detail.

Am experimenting now and trying to cast a section to get the proper print look in mine. My one old and brittle 47 original that still has printing intact is pretty worn but might give a decent impression. Also see another difference so will try to figure if there is a realistic way to get the 8 narrow ribs instead of the 7 with a wider one used in the 22nd series. Both wishes may be more than my feeble molding capabilities are up to but we shall see.

Posted on: 2014/11/8 16:07

|

|||

|

Howard

|

||||

|

||||

|

Re: 21-23 series rubber sill plates.

|

||||

|---|---|---|---|---|

|

Home away from home

|

Howard if you need any more pics, closer, different angle or otherwise, I'll be glad to take them. Richie.

Posted on: 2014/11/8 21:51

|

|||

|

||||

|

Re: 21-23 series rubber sill plates.

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Progress report on the sill moldings.

Am on the right track but have a ways to go. Made another test piece. Used the 48 sill as a starting point and cast that in silicone and then made a plaster copy. Found one of the old 47 sills with somewhat decent but not great detail left in the name portion. Maybe with a little more fine tuning it will work but would be nice to find a better one. Cast the name off that 47 piece and then cut and joined name sections. Narrowed and split the 48s wide inside rib and then added another long narrow rib using an acrylic strip to get the 47 pattern. Cast a new silicone mold using that composite plaster model as the pattern. Recast the sill and was not so pleased with the second test piece because the material I used cured full of bubbles. I don't have a proper strength pressure container for holding something large and not sure vacuum and a vacuum bag would work. The next step is find a different and decent open air casting compound in 80 to use that doesn't require vacuum or pressure to eliminate bubbles. The first test piece I made with the 40 material cast out nicely with no special technique but that formulation doesn't come in 80 -- only as high as 60.

Posted on: 2014/12/6 11:23

|

|||

|

Howard

|

||||

|

||||

|

Re: 21-23 series rubber sill plates.

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

This is a very interesting topic. I hope there will be updates.

Fish'n Jim, don't suppose you could post your findings regarding the "drawings" you discovered including the metal parts of the Packard rubber sill plates??? Sure want to know the brand of the molding supplies being used as well!!! Youtube has, as you know, many examples of casting and molding rubber parts--all very interesting, but for me this is more interesting. Looking forward to updates of your molding and casting quest for the perfect or almost perfect sill plate. Zougeride Exotic Tomball, Texas

Posted on: 2014/12/7 13:24

|

|||

|

||||

|

Re: 21-23 series rubber sill plates.

|

||||

|---|---|---|---|---|

|

Home away from home

|

Not sure what you're after, Z, but I have the drawings for the steel, SS trim, and the clips as well as the mat for the 23 series 2 dr. I got them from PAC and Studebaker Museum and had them digitized and made copies. These are different than the 4 dr. and fit a smaller # of vehicles.

I tried to contact the current parent of the clip manufacturer and got no response. I've got ideas how to modify the backer to work around. But I'm still focussing on the Cad at the moment, trying to get it completely road worthy. I'm close, like maybe today. I'm doing sheet metal repairs on the P and delayed the mat work. HH - I'm pretty sure these were compression moulded, so without a mould, press or injection moulder it'd be rather difficult to get them "purrfect". They would have put the backer in the mould, added the latex, and under heat and pressure cured the rubber. They'd be done by injection (RIM) probably today. If you don't "clean up" the impression molds after making casts and recasts, you leave stray marks/lose detail. That's why I was going the route of making a mould rather than an impression. This repro work is beyond the capability of the normal resto shops/average guy. I checked with Metro and they were interested but didn't have a large enuff press for the 2 dr. I have the name of the guy at Steele, which is up the road from me a piece, but I haven't discussed it yet. They don't per se have this capability from the parts they make but may have expertise. There are sheet metal stampers in the area here as well. But realistically, one can't afford to make hundreds of parts to get a few pairs.

Posted on: 2014/12/8 11:02

|

|||

|

||||

|

Re: 21-23 series rubber sill plates.

|

||||

|---|---|---|---|---|

|

Home away from home

|

I agree the originals were likely compression molded from rubber (although you don't normally use natural latex)compound, probably EPDM or SBR

RIM has the advantage of low cost tooling and cheap press time, but has other issues. Typical injection molding with a thermoplastic (80 SA f-PVC would work well) would certainly make good parts , but the tooling cost for so few parts is the issue. Even with a low cost/low volume tool like Kirksite or aluminum. So your cast RIM idea is not so bad, really. I think you will need to draw a vacuum on the mold to eliminate the voids.

Posted on: 2014/12/8 11:33

|

|||

|

||||

|

Re: 21-23 series rubber sill plates.

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

One of the suggestions of the mfg is to draw a vacuum on the mixed urethane to degas it as much as possible before pouring. With a bit of mods, I can have that capability with my pressure pot and AC vacuum pump. Am getting stuff together to make another lid so as to make a vacuum chamber. Will experiment with the remaining product left in the open container -- Don't think it is enough for another full sill but will at least be enough for a test to see if degassing first helps. Trick will be getting it degassed and poured within the open pot time.

Posted on: 2014/12/8 12:12

|

|||

|

Howard

|

||||

|

||||

|

Re: 21-23 series rubber sill plates.

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Thanks for the question Fish'n Jim. I am interested in the size of the metal plate and look of the clips. I guess posting the information would be of help even though my 1949 Packard is a Standard 4 door.

I remain very interested in the brand names of the molding material and look forward to seeing more on this subject illustrated with photographs. Just how tough or strong does the sill have to be??? All best wishes for success in the project. I look forward to learning a great deal from it. Zougeride "Exotic" Tomball, Texas

Posted on: 2014/12/9 10:31

|

|||

|

||||

(104.32 KB)

(104.32 KB)