|

Re: "Acceptable" bearing clearance

|

||||

|---|---|---|---|---|

|

Home away from home

|

I am actively looking- I think I have the rod bearings located, looking for mains. Calling a few sources looking for mains tomorrow.

Off-topic for my original thread, but I am contemplating boring the block to fit '38 and later 3.5" stock pistons, if I can find some NOS pistons. That would essentially turn my little ring and valve job into a full rebuild, but then it would be done, and I wouldn't have to worry about it. Any experience on this versus honing and new rings? (I did already hone the cylinders and got a good finish, but they have some taper)

Posted on: 2015/4/28 21:25

|

|||

|

1937 120 1092 - Original survivor for driving and continued preservation. Project blog / Registry

1937 115 1082 - Total basket case, partial restoration, sold Hershey 2015 Project blog / Registry |

||||

|

||||

|

Re: "Acceptable" bearing clearance

|

||||

|---|---|---|---|---|

|

Home away from home

|

Ken, if your are going to turn your 237 into a 245, then why not get a 245 engine? It has improved oiling and would be a much better way to go. I know this has been a learning journey for you and wanting to keep the one year only engine to go with your 115C, but sometimes a change in direction is a better path. Sailor to Sailor.

(o{}o)

Posted on: 2015/4/28 21:34

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

|

Re: "Acceptable" bearing clearance

|

||||

|---|---|---|---|---|

|

Home away from home

|

JW- that's a great thought, and I have learned a lot- my main reason is the sunk costs invested into my current block. Still a good thought though- anyone have a great running, non-smoking 245 long block?

Posted on: 2015/4/28 21:42

|

|||

|

1937 120 1092 - Original survivor for driving and continued preservation. Project blog / Registry

1937 115 1082 - Total basket case, partial restoration, sold Hershey 2015 Project blog / Registry |

||||

|

||||

|

Re: "Acceptable" bearing clearance

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote :

"..... boring the block to fit '38 and later 3.5" stock pistons...". According to JW above u'll pick up 12 cubes???? Don't waste your time. And: "... but they have some taper)" Ok. How much taper????

Posted on: 2015/4/28 22:23

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: "Acceptable" bearing clearance

|

||||

|---|---|---|---|---|

|

Home away from home

|

Does the engine currently have std or an oversize piston in it???

Posted on: 2015/4/28 22:58

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: "Acceptable" bearing clearance

|

||||

|---|---|---|---|---|

|

Home away from home

|

Standard, original pistons. I don't remember the taper, I last measured it (roughly) last fall, but it has taper!

Posted on: 2015/4/29 18:54

|

|||

|

1937 120 1092 - Original survivor for driving and continued preservation. Project blog / Registry

1937 115 1082 - Total basket case, partial restoration, sold Hershey 2015 Project blog / Registry |

||||

|

||||

|

Re: "Acceptable" bearing clearance

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

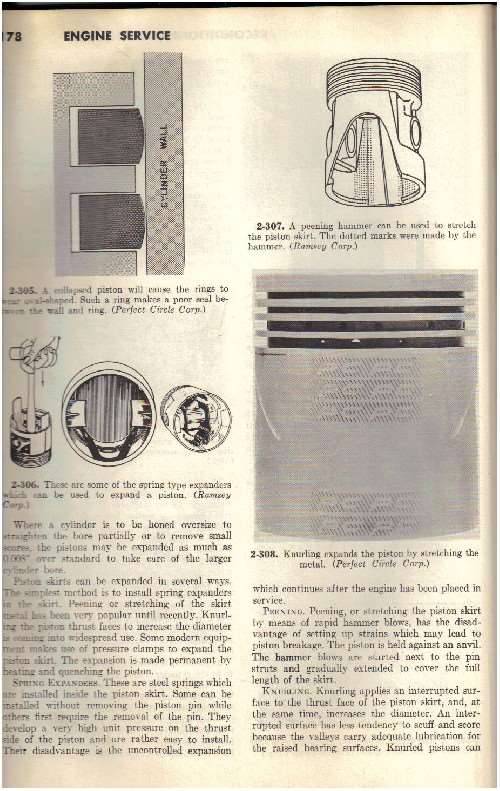

I've been down this road a few times back when a proper rebuild was financially out of the question. Short of a rebore and full engine rebuild there are some things to think about that can give serviceable results for perhaps 25,000 - 40,000 miles if the taper is moderate, say 0.007" or less. If the original pistons are in good condition they could be reused but check the ring grooves for wear, especially the top ring - worn grooves will allow the rings to "wobble" and wear the sharp edges rapidly and the solution to that is to recut the ring grooves to an oversize and fit with spacers; spacers should go above the new ring, not below! Piston ring suppliers at one time did supply special ring sets for worn but otherwise standard size bores though if no longer available even just a new set of standard rings should be quite satisfactory. If the ring grooves are recut, spacers are a commonly available item. You also might want to think about either installing piston expanders or having the skirts expanded (knurled) or peened to slightly increase the skirt diameter. Though there are those who frown on piston skirt knurling as being a short-lived solution, all the professional makers of engine rebuilding equipment offered tools for this and it is a viable option IMO. Again if reusing the existing pistons recut them for oversize wrist pins and new pin bushings for sure. And have the connecting rods straightened and aligned, and the big ends resized back to standard.

None of this will of course will match the result of a proper engine rebuild with new bores, but "in the day" engine overhauls like this were bread and butter for many a shop, I did a fair number myself. But it's all for naught unless you deal properly with the rod and main bearing clearances. Attachment from Glenn's outstanding book on engine service and rebuilding; though long out of print perhaps the very best book on auto service in general and engine rebuilding in particular.

Posted on: 2015/4/30 8:41

|

|||

|

||||

|

Re: "Acceptable" bearing clearance

|

||||

|---|---|---|---|---|

|

Home away from home

|

Owen, thanks for the detailed information and thoughts. What you say confirms me thought to bore and add new pistons. I was planning on stepping up to 3.5" pistons because I thought it would be easier to source OEM size stuff than oversize. I wasn't really thinking about the CI increase.

For those that don't remember my posts last fall, this started out as a ring and valve job, but I screwed up a valve seat, and the rest is history. I had one freeze crack that made me not want to rebuild the whole engine. Here is what has happened since September: 3.5" crack repaired with Lock-n-Stitch All valve guides replaced Valve job completed, 3 valves replaced 2 broken and one non-stock valve spring replaced Block decked (less than 0.010") Cylinders honed Block magnafluxed (two more small, non-leaking freeze cracks discovered, nothing else) Planned: Crank grind "Normal" rebuild tasks that I didn't do: Cam bearings Line bore the main bearings Bore the cylinders I am planning on the crank grind once I source bearings, and now I am thinking about boring the cylinders and fitting new pistons, wrist pins, etc. So, I have to decide if I want to put this engine away, find a running '38 or later engine like JW suggests, or do a more or less full rebuild. Owen, what is the full title of that book? I have looked for older engine rebuilding books before, but I haven't had any luck. Thanks!

Posted on: 2015/4/30 20:57

|

|||

|

1937 120 1092 - Original survivor for driving and continued preservation. Project blog / Registry

1937 115 1082 - Total basket case, partial restoration, sold Hershey 2015 Project blog / Registry |

||||

|

||||

|

Re: "Acceptable" bearing clearance

|

||||

|---|---|---|---|---|

|

Home away from home

|

All bearings located, plus I am going to do cam bearings.

Also ordered new pistons with rings, wrist pins, and spacers, so it is essentially a full rebuild. Thanks for all the info! I found the Glen's book too on Amazon, so I should be all set now.

Posted on: 2015/5/1 18:05

|

|||

|

1937 120 1092 - Original survivor for driving and continued preservation. Project blog / Registry

1937 115 1082 - Total basket case, partial restoration, sold Hershey 2015 Project blog / Registry |

||||

|

||||

(134.81 KB)

(134.81 KB)