|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Since using the fluid under pressure to move the seals is not feasible I wonder if compressed air would be strong enough to push them out or at least free them. If air from inside wasn't enough maybe a combination of air inside and alternate with a stream directed at the edges of the pieces from the outside would get behind and move them.

Posted on: 2015/10/28 22:02

|

|||

|

Howard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I think I just used those little tool pics to get mine out. that and a lot of luck.

also don't forget the grease/dust boots for the little balls on the T/L motor unit. Attach file:  (11.03 KB) (11.03 KB)

Posted on: 2015/10/29 13:45

|

|||

|

1937 Packard 138-CD Deluxe Touring Limousine

Maroon/Black 1090-1021 [url=https://packardinfo.com/xoops/html/modules/registry/View.php?ID=232]1955 Packard |

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Home away from home

|

An update on my transmission work (this may bore more than a few of you)

Some of you may recall that I made the decision some time ago to go with the 700R4 transmission using the conversion kit from Bendtsen's. I purchased the conversion kit back in the spring then spent the summer locating a transmission. There are photos below of the components in the kit (not the etching in the second image). Now I am not a transmission guy and surely never will be so I read everything online that I could find on the 700R4. It didn't take long to discover that not all 700R4 are created equal. To begin with there are two different sizes; one for the smaller V6 and the other for the 4.6 V6 and all V8. This was important as (for instance) the camero could have either one. The conversion kit only works with the large model. I also learned that while the 700R4 was made primarily from 82 to 92 the early models were to be avoided as they were prone to failure. Those issues were eventually worked out by GM but all the reputable rebuilders in my area told me to find an 87 to 92 model. Several didn't even want to work on the earlier model. I found a local one w/ a torque convertor on craigslist for $100. The guy said he pulled it from a 1990 camero. The plate from the conversion kit fit but I forgot to check the serial number. The next morning I discovered it was actually a 1984 model. The seller showed no interest in making it right so I was stuck with it. I couple weeks later a buddy and I went up the local Pull a Part (Louisville) and found a 1992 Caprice and pulled the tranny from that for $56. It was a police car with the MD8 type 700R4. That supposed to be a more heavy duty version of the 700R4. It will need to be rebuilt but I will worry about that in the spring. Hopefully I can unload the 84 model on craigslist and get most of my money back. While researching the 700R4 I discovered that the TV cable or knock down cable (that runs to the carburetor) were going to be an issue. I studied a couple at the pull a part while I was there got an idea how I might have to fabricate something. Then just out of curiosity I emailed Bob Bendtsen and asked him about it. After a few emails he sent me some pictures from the Packard he had done. He fabricated a plate that fit under the carburetor and welded some components to the plate that fit the TV cable and the problem was solved. I asked if he had that plate for sale and he said he did and to call the shop and speak to his assistant. I called later that day and he answered the phone. He sent me the plate for free (the pics he sent are at the bottom). I still need to get the small pieces as seen in the picture but that's not a problem. All my money this winter is for the engine and my time is on body work.

Posted on: 2015/10/31 18:40

|

|||

|

Stewart Ballard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Just popping in

|

I mostly lurk but I'll make a comment about the early 700R4. Don't believe everything bad someone tells you about the early trannies. We had one in a 1985 Astro van with the 4.8 liter V6. Bought it new. Put over 200,000 miles on it, which included some towing of a lightweight camper trailer and lots of miles in Southern California traffic. We did not have one thing go wrong with that transmission. Joe

Posted on: 2015/11/3 23:47

|

|||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Home away from home

|

Its a boring morning at work so I am researching automotive wiring.

Since my 400 is in a thousand and one pieces and all the wiring needs to be redone anyway I, of course, am going to go ahead and upgrade the whole system (12 volt & negative ground). I still have a while before I have to do the main harnesses but I am re-essembling the T/L controls now and trying to get that harness figured out. Unfortuantly, every 12 volt wiring chart I look at tells me something different. The longest wire on the T/L harness is the main lead (Red)off the starter (about 5')and the charts say to use a 14 quage. All others (Red, Yellow, Pink & Lt Green)are 16 guage. I am sure some of you have done this so any suggestions would be appreceaited. Like everything else on the web, you look at 10 different websites and you come away with 15 different answers. Thanks

Posted on: 2015/11/25 8:57

|

|||

|

Stewart Ballard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I'll throw in a wire size calculator I've used on a few occasions so you can have an even 16 opinions.gtsparkplugs.com/WireSizeCalc.html

If the motor does as Packard says then 14ga for a 5' run would be marginal but adequate in delivering full current and voltage. The 55 TL was fused at 20 amps and Packard mentioned in an early bulletin the motor would pull approx 17 amps at load. No mention of how much if any voltage drop. I believe in some cases that 17amps was found to be optimistic and reasons for reports of fuses blowing were listed. In 56 they went to a 30amp fuse (brake lights were added to that fuse which accounts for some of the extra) but I believe there were no further fuse issues after changing to 30 amps. Even though max capacity is needed in very short duration I think I would use 12ga in that particular red feed wire just to have a margin over. 16ga is fine for the others because the runs are short and current is low on two of the wires. 16ga in the 18" or so distance between the solenoids and motor can easily handle 20 amps and still deliver full voltage.

Posted on: 2015/11/25 10:45

|

|||

|

Howard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Home away from home

|

Opened up the T/L limit swith to make sure no moisture had got into it over the years. All within looks brand new so I am just cleaning up th exterior and adding fresh painting now. I found a replace cover, seal & grommet for the wiring at Max's.

I thought I took some pictures of the finished piece but I guess not. WIll take one next time I am out there. I am working on a new wiring harness for the T/L now. This is also slow going as I wanted to use all the right wire colors in case I have problems later on and need some of the PackardInfo, Info. Slowly getting all the other T/L components back together. I keep forgetting to take my laptop, with all the pictures, out with me so I can start putting it back together.

Posted on: 2015/12/20 17:45

|

|||

|

Stewart Ballard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Home away from home

|

I am currently doing some rust repair on the right rear quarter panel.

The nut inside that fender well that holds the fender skirt has to be completely rebuilt. Fabrication begins tonight or tomorrow night. Has anyone attempted this before and maybe has pictures of the completed project? I do not expect mine to look factory built, just strong enough to hold the skirt in place.

Posted on: 2015/12/29 11:03

|

|||

|

Stewart Ballard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

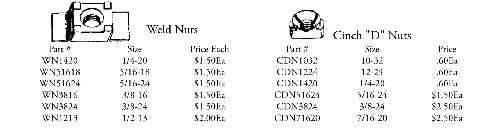

Can't offer photos or good suggestions but what about doubling up on the metal and then using a weld nut or D type cinch nut which could go in as a unit and maybe make it easier to position and weld. Can't remember if that is a sort of boxed in affair but would almost bet Packard used one or the other nuts originally. If it is boxed maybe you could overlap the bottom and weld in the nut then bend up to form the enclosure. Restoration Specialties has the 3/8-24 thread in both types.

Posted on: 2015/12/29 11:24

|

|||

|

Howard

|

||||

|

||||