|

Re: CLUNK !

|

||||

|---|---|---|---|---|

|

Home away from home

|

One could have only hoped but.....It is extremely hot here in central Texas. With that being said, I crawled under, disconnected the linkage at the trans. Shifter and disconnected linkage work fine. The lever on the side of the trans won't budge. So, next step....remove the trans pan and investigate there.....

It's ironic....The days of the shade tree mechanic are a thing of the past but, that is exactly my situation. A Packard on jack stands, sitting on a concrete pad, under a big live oak....LOL Any leads on a trans pan gasket ? Found a gasket....Fatsco Transmission Parts....$12.78

Posted on: 2017/6/22 19:04

|

|||

|

It is what it is....

|

||||

|

||||

|

Re: CLUNK !

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Interesting the shaft is totally locked. A dumb question but since the detents are fairly healthy, did you apply enough pressure to move it?

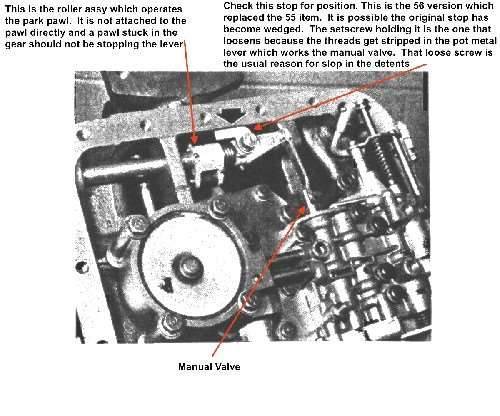

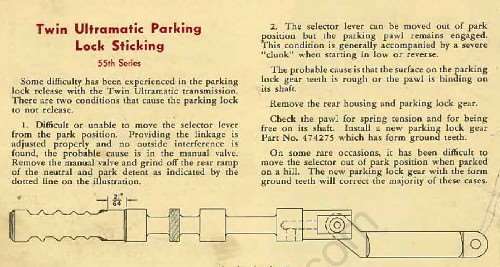

The park pawl does not directly attach to the shaft the lever operates so the usual parking pawl stuck in the gear reasons for staying in park may not apply. The lever and shaft rotates a roller assy which slides under the park pawl and pushes it against a spring and into mesh with the park gear. The disconnected outside lever should at least move to take it out even if the pawl stays engaged. When the lever moves it out of park the roller assy rotates away and the spring is what retracts the pawl. When you start looking, since the lever won't move at all, if you do not see anything obvious with something broken or bent the manual valve itself might be worth checking. With the later production of the car, I'd be surprised if it had the early problem item or at least if it hadn't been corrected or replaced when the car was new but anything is possible. If it does turn out to be the valve be advised that if you pull it out of the valve body it is a royal PIA to get it back in without some extra work. The detents are made by two round end spring loaded plungers opposite one another pushing into the series of rounded depressions toward the end of the valve. With the blunt end of the valve forced against them, the plungers cannot separate to allow the valve to slide between without some assistance from some kind of pointed object to force the plungers apart and let the valve follow the object while the plungers are still open. Hopefully Ross will have a better or easier idea to replace the valve if it has to come out to be worked on.

Posted on: 2017/6/22 19:59

|

|||

|

Howard

|

||||

|

||||

|

Re: CLUNK !

|

||||

|---|---|---|---|---|

|

Home away from home

|

I think you will find that the roller assy has rotated too far to the rear of the trans and now has to push the park pawl up into the parking gear in order to come back to its normal position. There is supposed to be a stop pin that keeps the roller assy from rotating too far, but in moderately abused transmissions that pin can be broken off and allow the roller to go too far and roll off the end of the parking pawl.

So the drill is: take a skinny screwdriver and push the parking pawl up into the parking gear. Rotate the driveshaft a bit to make sure the pawl engages all the way. While still holding the pawl up in place, rotate your shifter forward to any convenient gear other than park. Then till that stop pin is replaced, never ever use park again. Mr DeLorean was a brilliant engineer, but he was also a young one at the time and had not learned that one never puts a notch in the middle of a shaft subject to any bending loads. The modification to the manual valve described in the service counselor was an early grasp at straws to solve the various park problems. In my experience it is as futile as teats on a boar hog. While you have your pan off, check the tightness of the setscrew holding the manual valve lever to the shaft. Make it snug but beware they strip easily. Obtain a nice fresh 1/8" drill bit and a 1/8" x 1" rollpin. Drill clean through the manual valve lever and the shaft at some convenient location and then drive in the rollpin.

Posted on: 2017/6/22 20:29

|

|||

|

||||

|

Re: CLUNK !

|

||||

|---|---|---|---|---|

|

Home away from home

|

HH56 and Ross, Gentlemen, I thank you for the in depth tutorial. I wouldn't have had a clue what I would be looking for, other than the obvious, once I had removed the pan. This gives me a path forward. I have high hopes that, when the pan comes off, it will be a fix, as both of you have described....

I have to suspect that, it is an over travel issue as described, due to the lever being locked in place. We shall see.....Thank you again gentlemen...

Posted on: 2017/6/22 22:14

|

|||

|

It is what it is....

|

||||

|

||||

|

Re: CLUNK !

|

||||

|---|---|---|---|---|

|

Home away from home

|

This is just a thought

But..if the parking gear was magnetised..and parking pawl..or lever. Magnetnetised .by an electro magnet. To give .either N.N. or S.S. to repel ..away from each other. The electro magnet would be turned on when you shifted out of P.

Posted on: 2017/7/20 6:27

|

|||

|

Riki

|

||||

|

||||

|

Re: CLUNK !

|

||||

|---|---|---|---|---|

|

Home away from home

|

youtu.be/iOOEmbrhECo

Any wonder why shift motor would not get valve out of park... youtu.be/lMxbnL8HL6U

Posted on: 2017/8/1 21:26

|

|||

|

Riki

|

||||

|

||||

|

Re: CLUNK !

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Was that the original condition of the trans that failed?

I didn't see the shaft turning as the lever moved so I would say either the hole in the lever or the hole in the shaft is larger than the bolt or else is oval instead of round. I do hope that whomever did that isn't still working on Ultras. That stop is also butchered. With it bent out at the end like that it seems as if it may stop the lever a bit prematurely when going into reverse. The electric shift needs everything to line up per spec. Being off at reverse effects all the other positions because unlike the lever which can tolerate some slop in dropping into one of the other detents, the motor drive doesn't have much play between fingers and the dead spot on the sector. It will stop whether the valve is in the detent or not and could result in the valve not allowing full fluid flow to apply the clutches or pistons.

Posted on: 2017/8/1 21:48

|

|||

|

Howard

|

||||

|

||||

|

Re: CLUNK !

|

||||

|---|---|---|---|---|

|

Home away from home

|

Hi. H.

Yes the bolt hole has slop. But i tighten it and that held it. This is that 56 carrib. Convert. I have your shaft. Going to see any mods need to be made. It has the hole thru shaft. What p.d. me off for the manual lever the guy used 11/32nd nuts. I will change that to 3/8s. The reverse stop. The guy bent it. Guess that' was his upgrade. To get shaft out i had to hammer it to sorta straighten it out. Yes..this is what i got when i started to remove parts to get shaft out. That wire crimp tool i ground to hold 11/32hd nut..the guy doubled nuted Dollar store. I could not find an 11/3nd wrench..or a. Cheap ie to grind...not even h.f.

Posted on: 2017/8/1 22:49

|

|||

|

Riki

|

||||

|

||||

|

Re: CLUNK !

|

||||

|---|---|---|---|---|

|

Home away from home

|

H.h.He tried to drill i guess for pin..

The lever works perfect on the shaft you sent.. Not sure if i want to drill it all the way thru. The lever part. Going to drill for roll pin. And use an allen head type of bolt. A lttle longer too. I will also..drill the head of allen head and lever and use wire to keep head from moving out.

Posted on: 2017/8/2 1:26

|

|||

|

Riki

|

||||

|

||||

(145.67 KB)

(145.67 KB)