|

Re: Repairing '55 Clipper seat panels

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

As thin as it is you are probably correct in the vacuum forming. Problem with trying to do that today is the cost of the steel mold. I doubt there would be enough demand to even consider it being done by one of the professional companies.

In my previous lifetime one of the local hospitals wanted to have a formed flexible sterilizable cover for a set of tableside controls used in a new xray room. We had a local company that did stuff like that at the time but after we took the control module over to let them evaluate what would be needed on the mold to get a proper fitting cover the mold turned out to be so expensive the hospital decided an ordinary flat plastic sterile drape would work after all. That was in the days before casting materials were so readily available. Like making a fiberglass mold, possibly something could be made from an original side piece by using a high temp casting epoxy around it and then drilling the vacuum holes and otherwise modifying that casting for the vacuum process. I don't remember enough about how those covers are shaped to say for sure but being able to get the original cover out of a hard casting without damage might be the limiting factor.

Posted on: 2017/7/7 12:21

|

|||

|

Howard

|

||||

|

||||

|

Re: Repairing '55 Clipper seat panels

|

||||

|---|---|---|---|---|

|

Home away from home

|

I don't know for sure how the seat panel was made, but I do know that after 62 years, the plastic is going to need some reinforcing if I am to use this panel in the future.

If I recall correctly, the 1955 senior Packards like the 400 and Patrician did not have these plastic panels. Also, the power seat control in the 1956 Clipper is different from the one in the 1955. I am going to post some photos of the panels after I get home from work.

Posted on: 2017/7/7 13:12

|

|||

|

You can make a lot of really neat things from the parts left over after you rebuild your engine ...

|

||||

|

||||

|

Re: Repairing '55 Clipper seat panels

|

||||

|---|---|---|---|---|

|

Home away from home

|

You don't have to have an expensive steel mold to make one part, or a few parts. A mold made of wood or plaster will do. You could even take the old part if you can patch it up and cover it with bondo (don't forget mold release agent).

Posted on: 2017/7/7 14:18

|

|||

|

||||

|

Re: Repairing '55 Clipper seat panels

|

||||

|---|---|---|---|---|

|

Home away from home

|

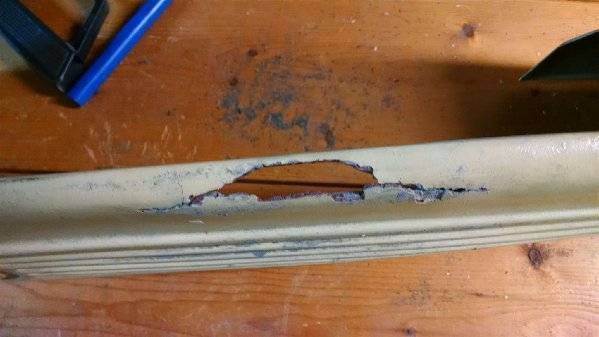

As I mentioned before, here is the driver's side panel showing the crack on the top and one of my ideas to repair it.

The blue pipe shown in the photos is flexible 1/2-inch PVC tubing. Although pliable is easy to cut, this tubing is very strong and I believe it would withstand the pressure applied by the steel seat anchoring tab.

Posted on: 2017/7/8 9:25

|

|||

|

You can make a lot of really neat things from the parts left over after you rebuild your engine ...

|

||||

|

||||

|

Re: Repairing '55 Clipper seat panels

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

You mentioned a tab on the seat. I presume that is what the slot in the tubing is for?? What does that tab look like? If it is square and sharp on top perhaps adding a piece of slotted metal pipe over that tab to spread the load would help. Make it small enough to fit inside the tubing. Even though the plastic tubing is tough I doubt it would take long for a square sharp tab to damage it too.

Posted on: 2017/7/8 9:46

|

|||

|

Howard

|

||||

|

||||

|

Re: Repairing '55 Clipper seat panels

|

||||

|---|---|---|---|---|

|

Home away from home

|

How about a picture of the seat and this metal that has inflated this damage?

Could the metal be shaved down any? Could the seat springs be stiffed to control the compression?

Posted on: 2017/7/8 10:46

|

|||

|

||||

|

Re: Repairing '55 Clipper seat panels

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

HH56 wrote: Quote:

...vacuum forming. Problem with trying to do that today is the cost of the steel mold. As best I recall, Studebaker used some sort of composite material for vacu-formed Avanti pieces. A one-sided affair, the mold was actually made to correspond to the inside shape of the part. In the case of the dash pad, the plastic sheet was already-grained - alleviating the need for costly etching of an outside mold.

Posted on: 2017/7/10 7:31

|

|||

|

||||

|

Re: Repairing '55 Clipper seat panels

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Quote:

...several other types of parts were drawn from Royalite for (then) current production. Meanwhile, in a separate thread on 55-56 changes, member 56executive kindly provided scans of an interesting factory document (in post #8), which includes a reference to this very material (see newfeatures 002.jpg image, item number 25).

Posted on: 2017/7/10 10:34

|

|||

|

||||

|

Re: Repairing '55 Clipper seat panels

|

||||

|---|---|---|---|---|

|

Home away from home

|

Well, I contacted a 3-D printing company in Tysons Corner, VA regarding my seat panel. I was told that due to the size of the panel, he would charge about $400 for the 3-D scanning alone. To get the panels actually 3-D printed in plastic, I would pay about $4,000!

I could do a hell of a lot on that car for four grand! I wonder how much he would charge to 3-D print a hubcap!

Posted on: 2017/7/10 12:31

|

|||

|

You can make a lot of really neat things from the parts left over after you rebuild your engine ...

|

||||

|

||||

(234.95 KB)

(234.95 KB)