|

Re: Packing rear axle bearings on a 39

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I think if the bar was turned 180 so the spring will fit the narrowed area on the bar over to the wide "notch" area on the shoe and then the main retracting springs are connected to the anchor pin the shoes will be drawn in enough and the cross bar will not be too short.

Before adjusting the shoes, Ross has often suggested it is a good idea to disconnect the emergency brake cable from the center point and pull or push it toward the lever a tiny bit so you can be sure there is complete slack and the lever and shoes are fully relaxed before the brakes are adjusted to the drum. That way you can be sure the emergency brake is completely released and not affecting the adjustment of the star wheel.

Posted on: 2019/2/14 21:53

|

|||

|

Howard

|

||||

|

||||

|

Re: Packing rear axle bearings on a 39

|

||||

|---|---|---|---|---|

|

Home away from home

|

And you are 100% correct Howard. Was using the "un-molested" left side as a guide but didn't mirror it on the right! DOH !!!

Posted on: 2019/2/14 21:58

|

|||

|

||||

|

Re: Packing rear axle bearings on a 39

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thank you all for your valuable input.

This has been bugging me so was determined to find out where it went this AM. Interesting, parts are not identical left to right, and this appears to be a simple spacer / ledge for the top of the shoes to sit on over the eccentric. The left side (original & grimy) fits pretty snug on the eccentric and is comprise of two parts as you can see in the pic. The right side, cleaned parts, fit very lose on the eccentric and is comprised of the flat plate and the washer with a lip on the ID. Further, no clue as to why the right side has that small hole in the plate, but not going on the premise that this has been worked on and this was not an original part Comments are welcome !

Posted on: 2019/2/15 13:44

|

|||

|

||||

|

Re: Packing rear axle bearings on a 39

|

||||

|---|---|---|---|---|

|

Home away from home

|

Making good progress, right side is done, working on left. I don't like the way the bearing looks so would like to replace it. If it fit tighter on the axle, would just repack and leave it be. It is loose on the axle, not spinning, but very loose. Right side, in contrast, seems like it was pressed on

To get the bearing off, I need to remove the key stock, which is refusing to budge. I have tried soaking in rust remover (there is no visible rust), rapping with a hammer, drift punch from the end, heat and just now, a large pair of side cutters to try and grab the end and pry upwards. Nothing seems to work So, 2 questions: Is the bearing supposed to be a loose fit? If not, what do I do, Loctite? How do I get the key off the shaft?

Posted on: 2019/2/18 19:25

|

|||

|

||||

|

Re: Packing rear axle bearings on a 39

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

On the key, any chance of tapping the point of an awl above the threads right at the end of the key where the bottom mating surface is flush with the shaft and then getting some kind of wedge action going to get the key end raised a bit. You might need to touch up where the awl point will undoubtedly gouge a bit but shouldn't be too much damage.

Posted on: 2019/2/18 19:55

|

|||

|

Howard

|

||||

|

||||

|

Re: Packing rear axle bearings on a 39

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Bearing is pressed on using very considerable force (multi-ton hydraulic press). If the new one is also going to be loose (don't just assume so) I'd stipple the shaft where the bearing will sit, additional use of Locktite couldn't hurt.

I've had good luck removing stuck keys by inserting a very thin jeweler's screwdriver between the slot and the bottom of the key and tapping with a light hammer.

Posted on: 2019/2/18 19:58

|

|||

|

||||

|

Re: Packing rear axle bearings on a 39

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks all

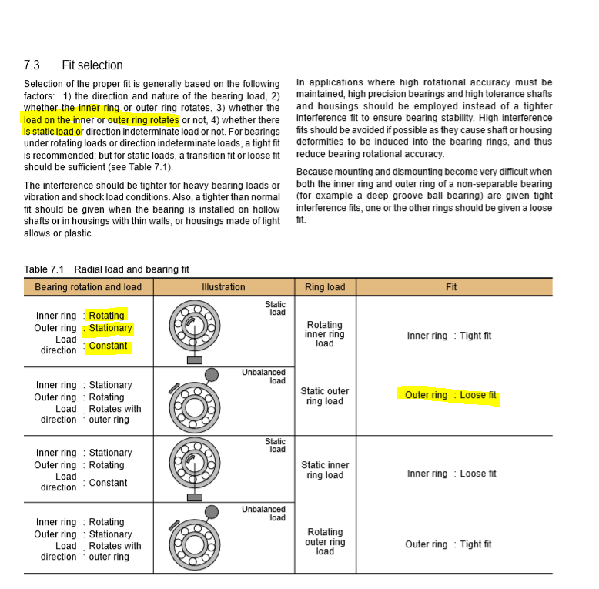

Tried with a sharpened awl, all it does is wedge itself in the corner of the key & keyway. I'll try again tomorrow I've read about stippling (some old time machinist call it a strawberry fit) but am reluctant to do so for 1 reason. Years ago, I worked for a company that used very large, 48" ID, as I recall bearings. If the mating surface of the outer race wasn't perfect, the mating surface finish affected the longevity of the bearing, which could be audibly heard (and measured using a transducer). Granted, these are only 1.5" ID bearings, but don't want to touch this again, if possible. Also did a web search, interetsing find. Not sure if I agree but this is from a bearing standard article.

Posted on: 2019/2/18 20:28

|

|||

|

||||

|

Re: Packing rear axle bearings on a 39

|

||||

|---|---|---|---|---|

|

Home away from home

|

Ended up using a Dremel to cut the key in half, lengthwise and it finally succumbed and came out. Not a bit of corrosion.

Replaced the wheel bearing with a new one and it was a press fit onto the axle, which made me feel better Word of caution, purchased the deluxe rebuild kit from Kanter as it included all hardware and new springs. It did not come with the two parking brake bar springs and the pins that hold the brake shoes in place along with the two caps and a spring are 3/8" too long in comparing to the ones that came off. Did not realize that until I troubleshot why I had a scraping noise despite backing off the 2 eccentrics and star wheel. The little spring cups were actually rubbing against the back side of the brake drum Called Kanter this AM to advise and were exceptionally cordial Finished doing brake eccentric adjustments as well as star wheel adjustments. Went back under car to connect parking brake cable equalizer pin and was surprised at the amount of slack in the parking brake cables. I now have Zero parking brake where just prior to replacing all these parts had great parking brakes. Not certain why the cables are so very slack, adjustments of the turnbuckle(?) will not suffice. Verified that the parking brake cables did not come loose from parking brake lever on rear shoes. Ideas?

Posted on: 2019/2/27 0:46

|

|||

|

||||

|

Re: Packing rear axle bearings on a 39

|

||||

|---|---|---|---|---|

|

Home away from home

|

Our brake hardware kits are based off an industry standard. Meaning the kit contains the hardware that is most likely to fail do you excessive heat and movement. The anti rattle springs that go over the parking brake bar from an industry standard not considered a wear item and is not a standard part in a brake hardware kit. Pertaining to the problem with the hold down pins/nails that you received. Can you tell me what is the number stamped into the end of pins that came in the kit? It is normally either a one or two digit number? Also what was the number on your original pins?

We would like to resolve your issue. Thanks James From Kanter Auto Products

Posted on: 2019/3/1 13:43

|

|||

|

||||

(48.88 KB)

(48.88 KB)

(185.11 KB)

(185.11 KB)