|

Re: Overdrive wiring issue

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Checked my solenoid and the plunger will push in approx 1/2 inch but it pushes against a fairly healthy spring so needs quite a bit of pressure to move it. I don't have a push pull scale so no easy way to measure how much pressure it takes but it does take several pounds of force. Is your plunger relatively easy or hard to push to extend past the contacts?

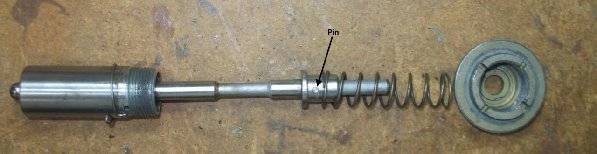

The plunger appears to be made in four pieces -- a magnetic attraction piece for the core, a machined shaft, a spring seat held by a pin thru the plunger shaft and a plastic insulator at the tip to touch and move the contacts. As long as the pin is intact thru the shaft and spring seat the plunger shaft will not pull out of the solenoid magnetic core piece or move more than it takes to compress the spring so the coils touch -- about 1/2 inch. If something is wrong with the spring the spring might not be putting enough pressure against the shaft to keep inertia from moving it backwards too far. Looking at the primary reason for the spring, I guess some movement would be expected. During engagement the pawl will stop at the balk ring before the OD is in a position where the pawl can engage the sun gear so some flexibility there is needed to allow the magnetic core piece proper movement. The plunger retracting pulling the weight of the core piece and pawl then having a sudden stop as the plunger hits the contact plate at end of travel would be quite a jar at release unless the shaft was able to extend a tiny bit farther against the spring to lessen the shock. In any case I would think excess travel should be minimal with a proper spring and plunger ball locked into the pawl which in turn is captured in the OD case so it will be interesting to know what you find is causing yours to extend further.

Posted on: 2019/4/17 19:16

|

|||

|

Howard

|

||||

|

||||

Happy 4th of July and welcome to Packard Motor Car Information! If you're new here, please register for a free account.

(126.29 KB)

(126.29 KB)

Who is John Galt?

Who is John Galt?