|

Re: Oil Filter Plumbing

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Before the 51 engines apparently there was no return port on the 288/327 blocks so if you have solid lifters the filter is just inline with the lifter gallery port such as shown in this engine drawing.

If you have hydraulic lifters then it becomes more of a question. There were early 356 engines where the filter inline with the lifter gallery caused problems. After some filter version changes Packard finally went to the bypass filter plumbing at that time and had mechanics drill a hole into the crankcase for adding a return port which was included on the later 356 blocks. To the best of my knowledge that was never an official thing for the 288/327 blocks. Since the problem was not on all 356 engines and the later 288/327 lifters are of a different design perhaps the issue never surfaced on the later blocks. It was not until the 51 engines that it was bypass on all whether solid or hydraulic but if the inline filter causes problems there is no reason the 356 solution could not be applied to the other blocks since the internal oil flow is the same. One question on a missing plug would be if you installed the plug with the small hole at the front of the lifter gallery which lets a metered amount of oil enter the timing chain area. I believe there is another plug at the rear of the gallery that is behind the bellhousing. If missing that one there would probably be a leak somewhere. I don't remember how deep it is as to whether you could see the leak or if a leak would blocked by the bellhousing or be draining into the crankcase.

Posted on: 2019/6/17 11:53

|

|||

|

Howard

|

||||

|

||||

|

Re: Oil Filter Plumbing

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

You don't give much info to analyze. How about some actual pressure numbers? Cold idle, hot idle, hot at road speed? At what pressure is the oil pump relief valve opening (max cold pressure)?

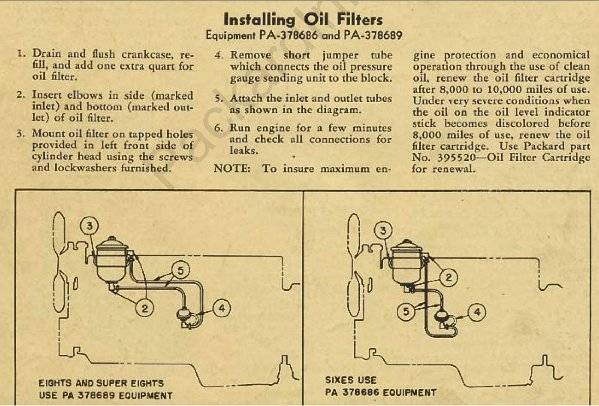

What service if any did you do on the oil pump as part of the rebuild? Did you check the relief valve spring length or try adding a shim? Very thin gasket used on pump cover? Cover smooth and free of wear pattern? Have you checked the engine bearing clearances? An oil filter install schematic is on site here, someone will surely locate it for you.

Posted on: 2019/6/17 11:55

|

|||

|

||||

|

Re: Oil Filter Plumbing

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Cold idle = 40psi

Hot idle = 5psi Hot at 40mph = 15psi Oil pump, replaced the relief spring with new. New thin gasket, measured clearances in pump within spec. No shim. Engine bearing measured clearances .001-.003 with new .001 oversize bearings. Thanks for the questions...hope this helps.

Posted on: 2019/6/17 13:53

|

|||

|

||||

|

Re: Oil Filter Plumbing

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

It doesn't seem like the hot idle number is too bad although 40 seems a bit high for cold. 40 is what Packard said the driving speed number would be so maybe cold oil is just that much thicker and the relief valve is doing it's job. Recommended aftermarket replacement sender specs are 6psi for the models with idiot lights. I have not found an actual for certain spec for the Packard switch but with Packard saying the light may flicker or come on at idle speed, 5 would seem in the ballpark but maybe a tad low. Wouldn't want to be too much lower though. 15 is definitely low and with thinned oil due to heat maybe the pump is the issue.

What are you calling a thin gasket? The thickness of tracing or onion skin paper is about as thick as the pump can stand without having problems and some have reported issues when making gaskets out of regular gasket material. No idea how thin the gasket material you have might be in relation to the paper but if any thicker maybe the issue.

Posted on: 2019/6/17 14:04

|

|||

|

Howard

|

||||

|

||||

|

Re: Oil Filter Plumbing

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I agree, you've got low oil pressure, the hot pressure at road speed is of particular concern. The cold idle pressure suggests the oil pump and relief valve are performing satisfactorily. Have you obtained these pressure readings with a known, good and accurate gauge? And connected where? And I should have asked, what viscosity oil?

Care to summarize the major details of the engine rebuild?

Posted on: 2019/6/17 15:38

|

|||

|

||||

|

Re: Oil Filter Plumbing

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

I bought a manual gauge and hooked it up in place of the sender.

Rebuild details... Machine shop: Boiled the block peen and bore the valve guides. ground the new valves and honed the seats. cleaned and measured the crank installed new cam bearings and checked the cam OK. recommended .001 oversize bearings for the crank which I sourced from Kanter. installed rings on pistons. My work follows.. installed crank using .001 oversize bearings using assembly lube on all rotating parts. Rotated crank by hand slightly tight but ok. measured clearances to spec with Plastigauge. installed pistons in cylinders. installed rod bearings assembled front of the engine for install. All parts removed were bagged and tagged for assembly. replaced clutch with newly rebuilt hung the transmission ran engine on stand for break in (at this point I had 40psi cold and 15psi at hot idle) installed engine.

Posted on: 2019/6/17 18:35

|

|||

|

||||

|

Re: Oil Filter Plumbing

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

What oil pressures were you experiencing prior to your rebuild? The existing main and rod bearings at that time were STD?

Posted on: 2019/6/17 19:50

|

|||

|

||||

|

Re: Oil Filter Plumbing

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Prior to the rebuild the engine did not run, so no oil pressure history. STD bearings.

Mark

Posted on: 2019/6/17 23:37

|

|||

|

||||

(244.05 KB)

(244.05 KB)