|

Re: Bolt torque specification 1934 Super Eight

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

There were few or no torque specifications in that era, they really came into play primarily as a result of WWII manufacturing experience. Just tighten consistent with the bolt grade and thread size. There was no sequence published nor is one necessary. If you're concerned about your plate being warped, starting in the center and working towards the ends would be logical.

Posted on: 2019/7/14 6:36

|

|||

|

||||

|

Re: Bolt torque specification 1934 Super Eight

|

||||

|---|---|---|---|---|

|

Home away from home

|

You can reference ASTM tables for torque standards. They have lots of different types.

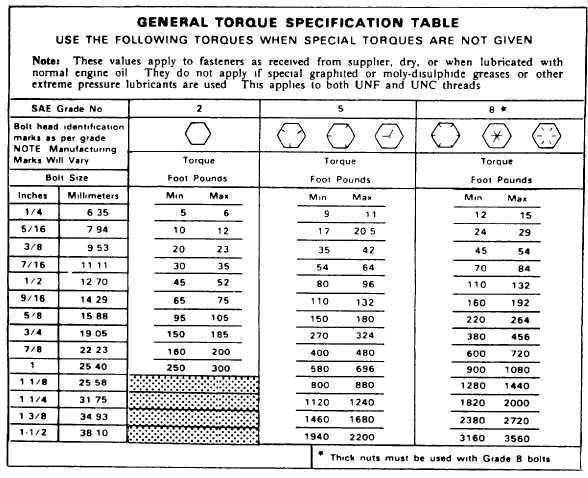

The table below is one example. I would use the grade 2 figure for paper gaskets and gradual hand tight for imitation cork gaskets. If you wanted to be super scientific you would put a bore gauge into the cylinders to check for any distortion from uneven torque. The system is not pressurized so lots of torque is not necessary. Attach file:  (84.38 KB) (84.38 KB)

Posted on: 2019/7/14 7:25

|

|||

|

||||

|

Re: Bolt torque specification 1934 Super Eight

|

||||

|---|---|---|---|---|

|

Quite a regular

|

Thank you for the response. While I suspected that torque spec were probably not published i was surprised recently when I have found them for a Ford Model A (including sequence for head bolts). I thought that maybe enough folks would have gone through the procedure to advise on value.

I will use the ASTM data. Regards Super8

Posted on: 2019/7/14 16:06

|

|||

|

||||

|

Re: Bolt torque specification 1934 Super Eight

|

||||

|---|---|---|---|---|

|

Home away from home

|

On cylinder heads I used the postwar chart as a guide.

It is a modified cross pattern. I think those thick gaskets tend to compress as they age and thus the issue of multiple torque. However, in the old days we didn't have that problem.

Posted on: 2019/7/15 11:38

|

|||

|

||||