|

Re: WOOD REPAIR QUESTION

|

||||

|---|---|---|---|---|

|

Quite a regular

|

Hi Craig - like most of the wood, the joints are covered by sheet metal. There is a good and simple reason for this. The wood skeleton was assembled complete before any sheet metal went on.

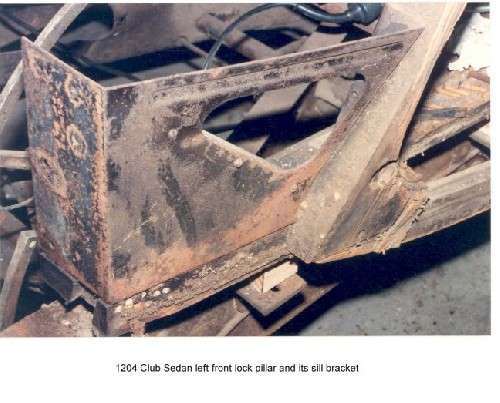

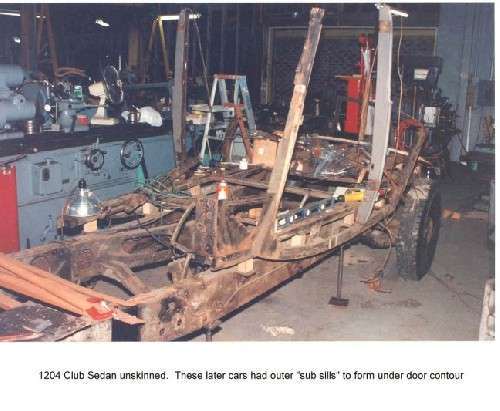

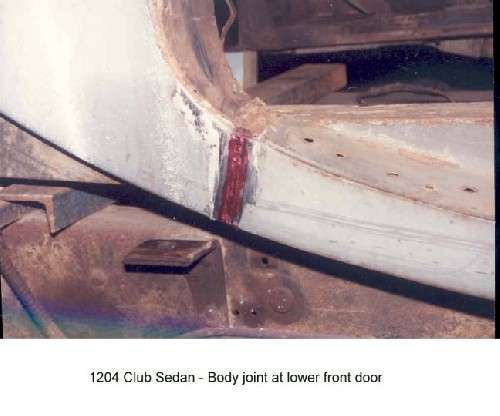

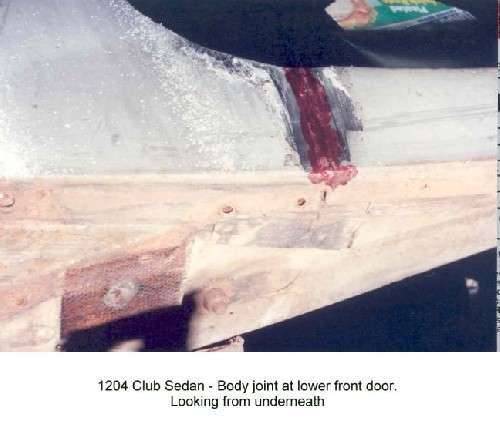

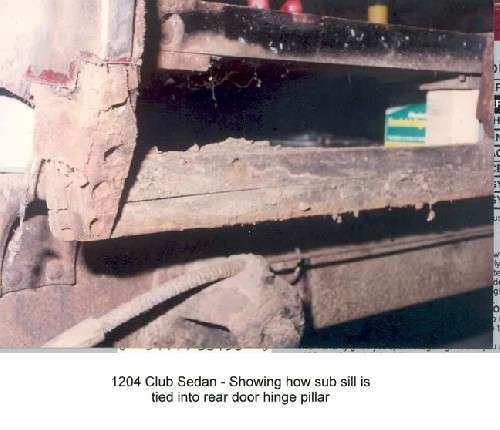

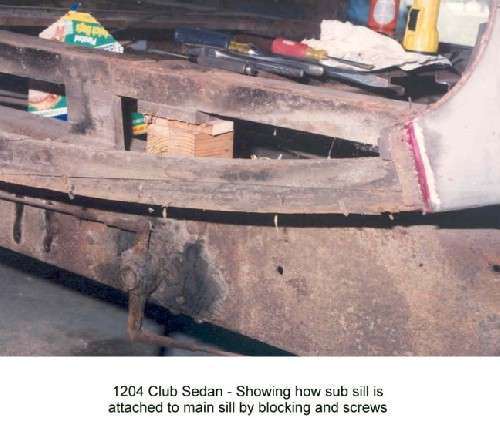

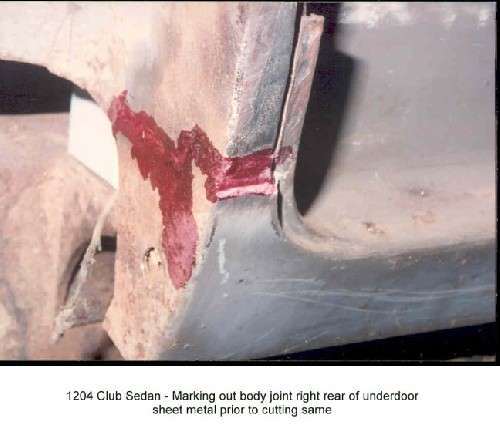

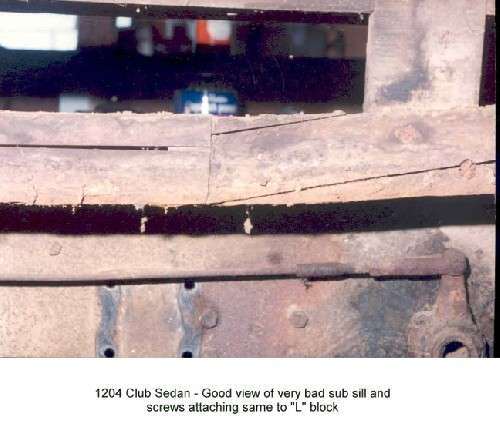

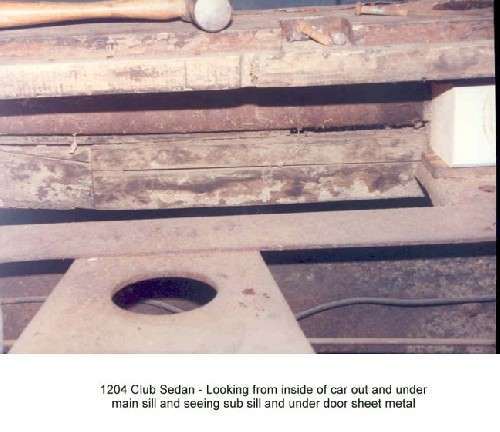

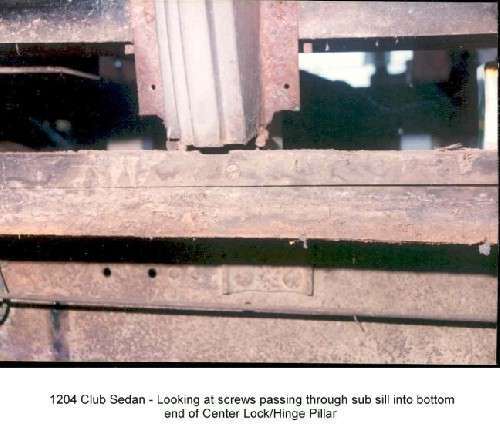

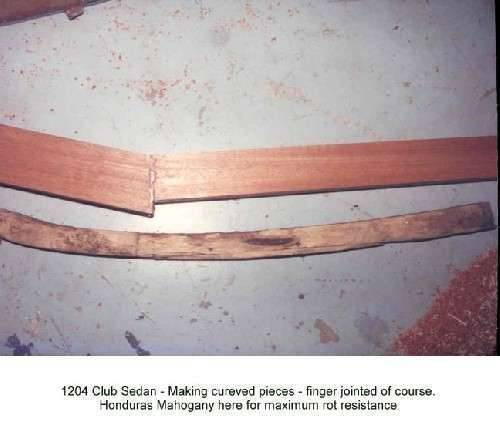

I think you are referring to the sub sills. These are tied into not only front and rear posts, but are also attached to main sills by blocking and screws. These are the wood pieces that form the curved contour below the door openings These 1204 Club Sedan photos may be helpful, maybe not. John Oder On edit: Here a few more. You can see how you can't even see screws until sheet metal down there came off. There is about 30 nails along bottom into sub sill. JO

Posted on: 2009/2/10 20:55

|

|||

|

||||

|

Re: WOOD REPAIR QUESTION

|

||||

|---|---|---|---|---|

|

Quite a regular

|

thanks john for the great photos,

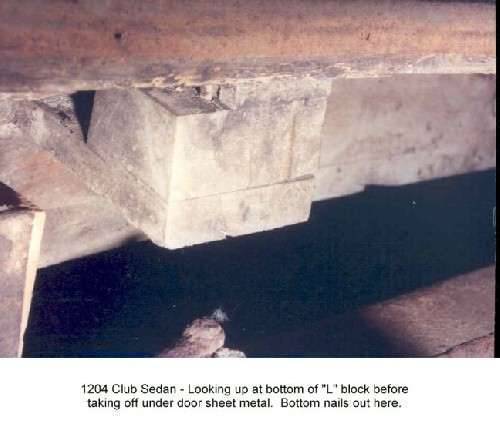

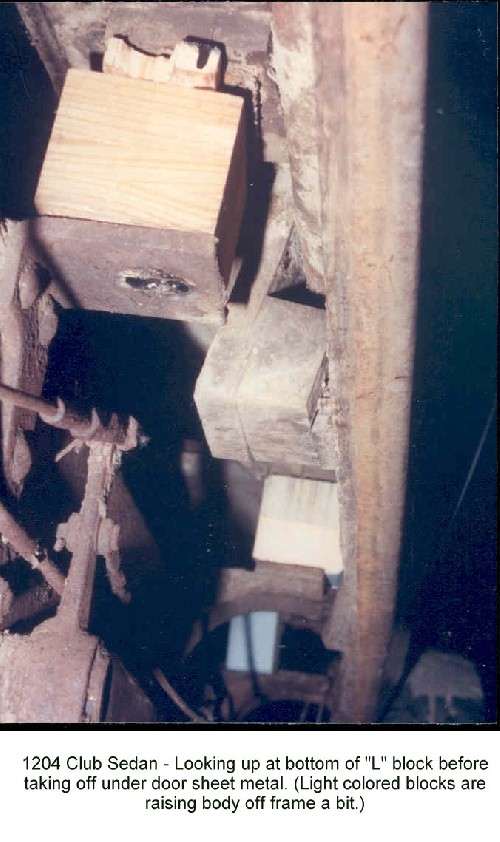

i see in the last photo, the block or "L" block that hangs down to keep the lower sill wood in. can they be removed without removing the sheetmetal? or do i have to remove sheet metal inorder to do a good repair here. on this car, the left side sill was replaced by splitting that "L" block and a new piece was inserted to just to the door jamb between front and rear doors. and the left front door post wood was also replaced, but done poorly and i need to make some modifications to it. i need to replace the rest to the rear fender and the entire piece on the right side. from the front door post all the way back. this appears to be the only bad wood i have found so far.

Posted on: 2009/2/11 2:08

|

|||

|

||||

|

Re: WOOD REPAIR QUESTION

|

||||

|---|---|---|---|---|

|

Quite a regular

|

Hi Craig - glad to help.

The "L" blocks are held on to the sub sill by two screws passing through from the outside of the sub sill and screwing into the "L" block. You can look hard at photo and see their rusty little heads. The upper end of the "L" block has screws passing through it and screwing into outer edge of main sill. Neither of these two pair of screws can been seen, much less worked on, until the sheet metal under the door opening comes off. John Oder On edit - some more photos that may help. JO Attach file:  (29.90 KB) (29.90 KB)  (36.91 KB) (36.91 KB)  (35.81 KB) (35.81 KB)  (38.37 KB) (38.37 KB)  (30.76 KB) (30.76 KB)  (62.13 KB) (62.13 KB)  (36.92 KB) (36.92 KB)  (29.75 KB) (29.75 KB)  (42.37 KB) (42.37 KB)

Posted on: 2009/2/11 8:21

|

|||

|

||||

|

Re: WOOD REPAIR QUESTION

|

||||

|---|---|---|---|---|

|

Quite a regular

|

THANKS FOR THE LATEST PHOTOS, THEY ARE REAL BIG HELP. I WILL GET WITH THE OWNER ON THIS AND SEE WHAT THEY WANT US TO DO HERE.

CRAIG

Posted on: 2009/2/11 12:10

|

|||

|

||||

|

Re: WOOD REPAIR QUESTION

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Don't mean to deter you, but have you considered chemical repair? These are widely used architecturally, and have the usual weakness that they have great strength in compression, but not so much in tension. They are also widely used in wooden boat repair.

Except of "git rot" for boats, most of the leading names escape me. The marine products might be preferable for a project like this. I just Googled "epoxy wood repair" and got this: http://repairnotes.blogspot.com/

Posted on: 2009/2/13 22:54

|

|||

|

||||

|

Re: WOOD REPAIR QUESTION

|

||||

|---|---|---|---|---|

|

Quite a regular

|

thanks for the link. I have considered this, but was advised against it, due to distortaion of the outside metal.

see the restoration details on a project attempted using wood repair products. ccrutah.com/resclp01.html although this stuff looks pretty good. but unfortunalty, on the left side of this project, most of the wood is beyond repair. the right side maybe. but since i have to replace the complete left side. might just do the same on the right. more research is needed. craig

Posted on: 2009/2/13 23:39

|

|||

|

||||