|

Re: DIY Torsion level control switch conversion

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Quote:

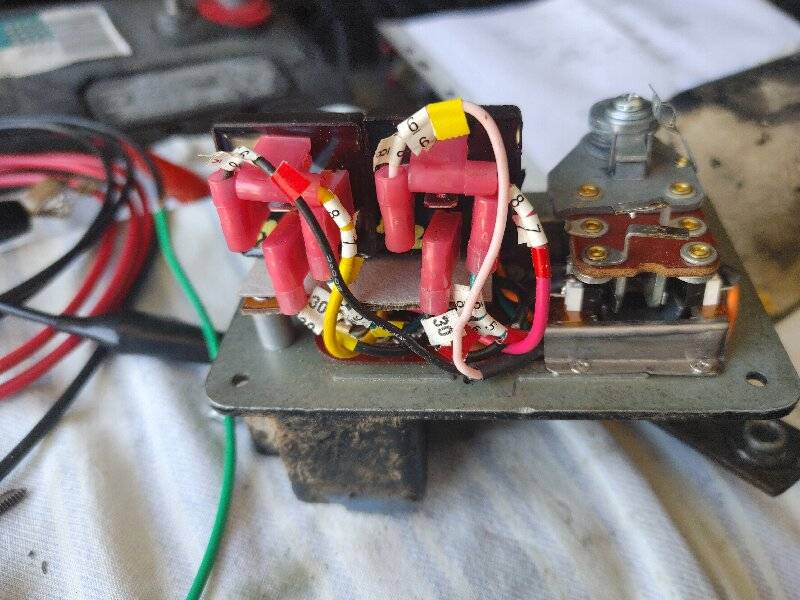

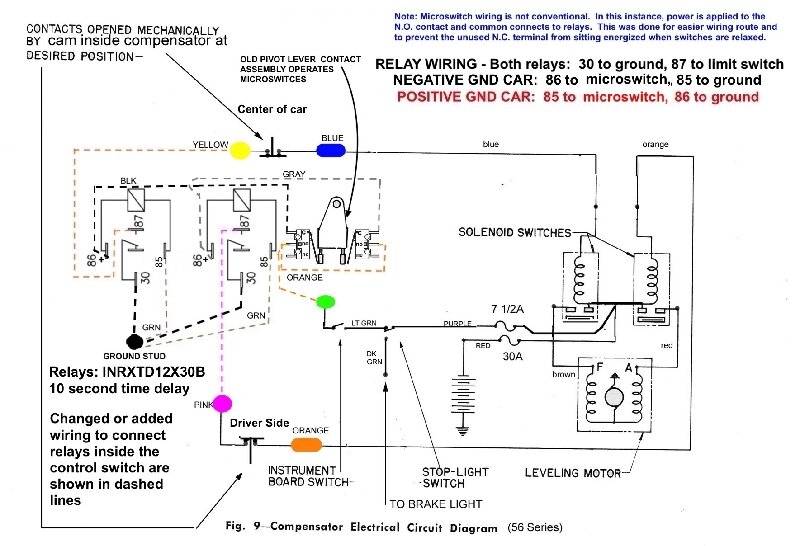

The perils of publishing a diagram before being able to fully test but fortunately an easy fix. In order for the proper relay to be energized it is actually move each wire connecting to 86+ to the opposite relay. Those are the GRAY and BLACK wires powering the relays and coming from the microswitches. Just needed to switch to the correct relay. The pink wire out to the solenoid stays as is.

Posted on: 2023/6/4 16:43

|

|||

|

Howard

|

||||

|

||||

|

Re: DIY Torsion level control switch conversion

|

||||

|---|---|---|---|---|

|

Home away from home

|

Still trying to get level.

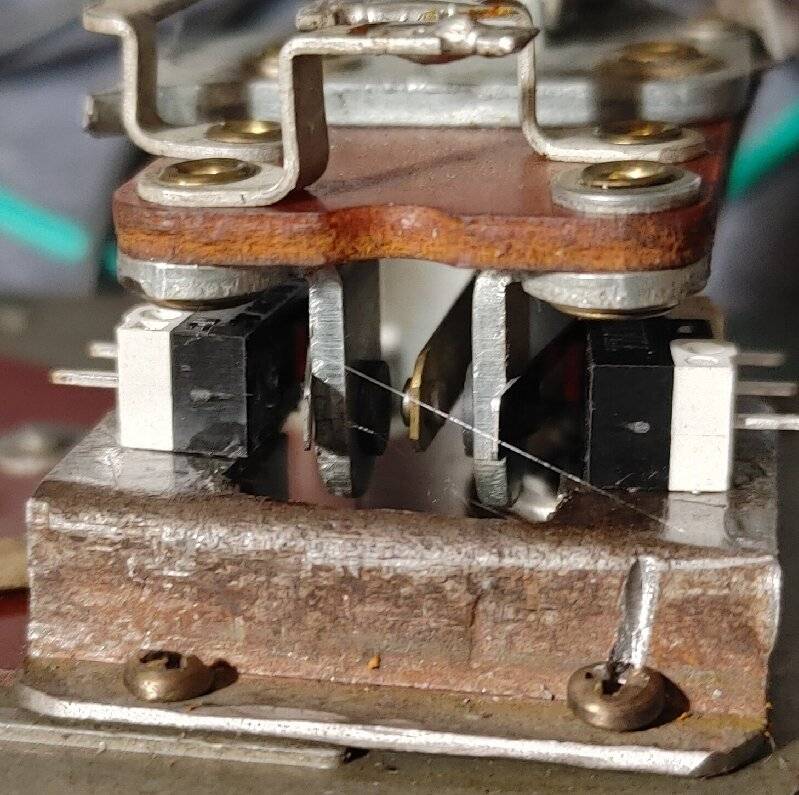

But one thing .. I think is that the micro switches need to be closer. Before I could push down on car and t l would kick in. With this. Need to keep weight on . So I'm sure its that the micro switches are to far apart. For this the levers could be bent. . I think just the gap needs to be closer.. R and D. But its works fine otherwise..

Posted on: 2023/6/4 20:56

|

|||

|

Riki

|

||||

|

||||

|

Re: DIY Torsion level control switch conversion

|

||||

|---|---|---|---|---|

|

Home away from home

|

1 inch aluminum channel 1/16

Easy to bend. So bracket is doable..

Posted on: 2023/6/6 20:58

|

|||

|

Riki

|

||||

|

||||

|

Re: DIY Torsion level control switch conversion

|

||||

|---|---|---|---|---|

|

Home away from home

|

Aluminum is not the way to go. Split . while cutting gap.

Going to try 16 gauge angle. Aluminum is to thick to fit behind casting line.

Posted on: 2023/6/9 2:57

|

|||

|

Riki

|

||||

|

||||

|

Re: DIY Torsion level control switch conversion

|

||||

|---|---|---|---|---|

|

Home away from home

|

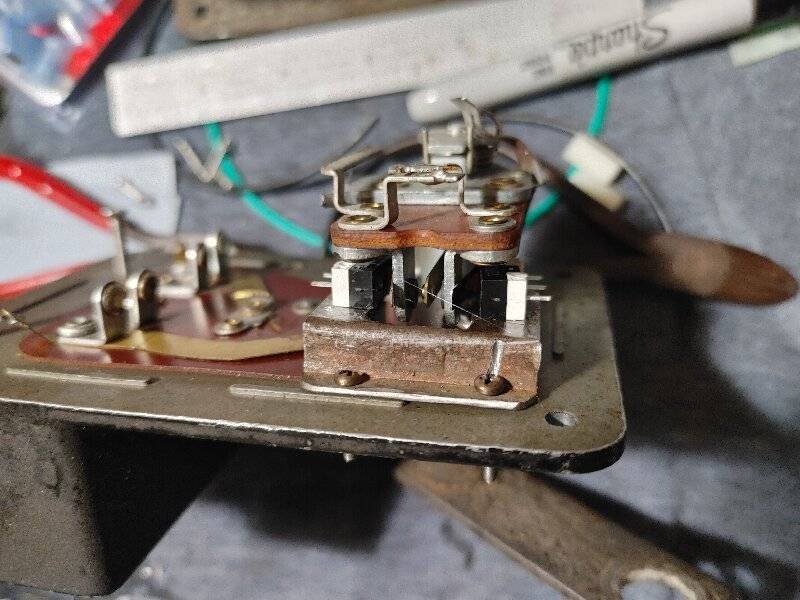

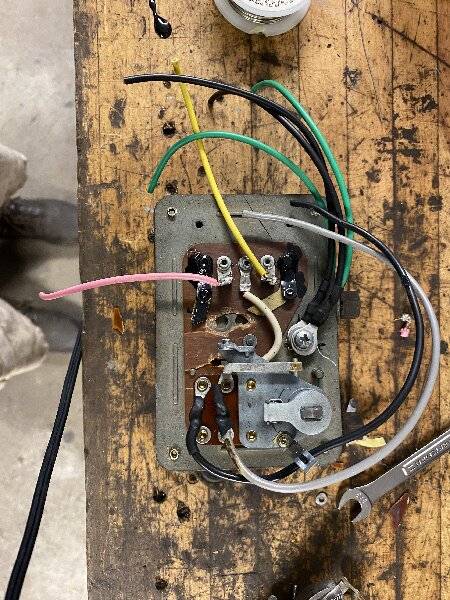

After a few tries .

16 gauge sheet metal. Step 1/4 inch. Using a machinist vise you can get a sharp bend. Right now micro switches are held with rubber cement. For picture. But with center contact makes it easy to adjust switch.

Posted on: 2023/6/10 2:33

|

|||

|

Riki

|

||||

|

||||

|

Re: DIY Torsion level control switch conversion

|

||||

|---|---|---|---|---|

|

Home away from home

|

The way to set up micro switches.

The center point. When you turn lever Makes contact with other point set set switch to click.on. This works like original.. Time delay. Tested by my modified compensator switch..

Posted on: 2023/6/13 0:29

|

|||

|

Riki

|

||||

|

||||

|

Re: DIY Torsion level control switch conversion

|

||||

|---|---|---|---|---|

|

Home away from home

|

I can not thank you guys enough for doing this! saved me a lot of hassle!

I did do something a little different. Howard is correct in that you NEED a powerful solder gun. Mine was nowhere near the 200W like he suggested, and the ones at work only went up to 140W. But I found another way: so since your modifying the switch to the point original parts would no longer work, I cut one side of the contact that the relays would interact with and hammered out the other side. Doing so created a hole on top of that "L" contact. From there I wrapped the wire into that hole and around the top of the contact and a regular soldering iron was able to solder it properly.

Posted on: 2023/6/23 8:42

|

|||

|

||||

|

Re: DIY Torsion level control switch conversion

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Sounds like progress and an easy solution for smaller irons. Just remember switch was not tested on the car before the wiring diagram was posted. Riki found the microswitch version I finally sent to him for testing worked backward. The non microswitch relay only version may be OK or it may also be backwards.

If you push down on the rear of the car and it wants to go down farther you will need to reverse the wires coming from the pivot switch or microswitches going to terminal 86 on each relay. That will change which relay comes in and determines whether the car goes up or down.

Posted on: 2023/6/23 8:49

|

|||

|

Howard

|

||||

|

||||

|

Re: DIY Torsion level control switch conversion

|

||||

|---|---|---|---|---|

|

Home away from home

|

Pink wire/relay.

Is up.. Relay

Posted on: 2023/6/23 9:18

|

|||

|

Riki

|

||||

|

||||

20230604_125358_HDR.jpg (185.01 KB)

20230604_125358_HDR.jpg (185.01 KB)