|

Re: Bendix Treadle Vac Study- Serioius Business!!

|

||||

|---|---|---|---|---|

|

Home away from home

|

Over the last 12 years many statements have been made similar to the following recent two statements:

"I'll entrust that to someone with a good reputation that does several hundred of these units a year -..." "It is the owners responsibility to ensure they take the unit to a knowledgeable rebuilder." Ok. Go ahead. Specifically NAME them! Lets make a list of such rebuilders.

Posted on: 2010/12/3 16:26

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: Bendix Treadle Vac Study- Serioius Business!!

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I've used Ed Strain in Florida.

Posted on: 2010/12/3 17:04

|

|||

|

||||

|

Re: Bendix Treadle Vac Study- Serioius Business!!

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

IMHO, the level of difficulty to perform a minor overhaul of the BTV (that is, the hydraulic section) lies somewhere between that of a fuel pump and carburetor rebuild. The factory shop manual was all I needed do the job, but Ross Miller's How-To offers a fresh perspective on these units, after decades of service and/or non-use, and provides some excellent tips.

If a professional rebuild was necessary in all cases, then why were kits available through retail parts stores for so many years? Why would even reputable parts vendors be offering a reproduction minor kit to the public, today? Years ago, when you you needed a new hydraulic plunger, but NOS was NLA, the typical answer was use a professional rebuilder. I know several people who simply had one made locally, and that was my plan. Since then, Kanter began offering that in stainless. Availability of the compensator port valve spring is just more of the same. Granted, if the casting requires machine work or replacement or you've got problems with the vacuum piston assembly, then most would probably do better to turn to a rebuilder. I'm fully confident and competent to do all but the machine work myself, for the brakes on my own Packards, but I won't do the work for hire.

Posted on: 2010/12/3 18:42

|

|||

|

||||

|

Re: Bendix Treadle Vac Study- Serioius Business!!

|

||||

|---|---|---|---|---|

|

Home away from home

|

Packard8 wrote:

Quote: I hear White Post is good. When I sent the BTV for the '54 convert to Dallas (and it had to be redone) White Post was $350 for a BTV rebuild at that time, and as I recall that included a brass sleeved master. White Post rebuilt one of mine and it failed after about 1 year. It included the sleeved master too. Craig

Posted on: 2010/12/3 18:42

|

|||

|

Nuke them from orbit, it's the only way to be sure! Ellen Ripley "Aliens"

Time flies like an arrow. Frui |

||||

|

||||

|

Re: Bendix Treadle Vac Study- Serioius Business!!

|

||||

|---|---|---|---|---|

|

Home away from home

|

What was sleeved on the master? The seal works on the piston rod.

Posted on: 2010/12/3 19:20

|

|||

|

||||

|

Re: Bendix Treadle Vac Study- Serioius Business!!

|

||||

|---|---|---|---|---|

|

Home away from home

|

The sleeve was a major controversy in a recent BTV thread of about a month ago.

To date, the best we can determine is that the RECESS for the SEAL is sleeved. edit: Of course that assumes that ANY kind of sleeve was ACTUALY installed at all.

Posted on: 2010/12/3 20:05

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: Bendix Treadle Vac Study- Serioius Business!!

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Certainly, when the bore in a conventional cast-iron master cylinder (or wheel cylinder) has become badly pitted and replacements are NLA, sleeving is necessary to achieve a good seal and prevent damage to the rubber cup seals which slide through the bore.

In the Treadle Vac, however, the rubber hydraulic seal never really moves. Instead, the plunger/piston slides through that fixed seal, pushing brake fluid out from the otherwise closed chamber to the wheel cylinders by simple displacement. It's when that plunger surface becomes pitted that the hydraulic seal could be damaged. As such, the BTV master cylinder body doesn't require sleeving in the conventional sense; replacing the plunger is the solution in that case. However, I now realize why some BTVs might require sleeving. The underlying reason can be found in the 55-56 shop manual section on brakes, where you'll find a paragraph on inspection of the disassembled unit, advising the rebuilder to: Quote: Examine the hydraulic cylinder bore 1" from the open end. The surface must be free from scores, deep scratches, or corrosion, and be satisfactory for sealing with rubber hydraulic seal. I can see where such issues with the die-cast master cylinder body in that area could cause leakage into the vacuum shell, and how they would likely be stopped by sleeving just that portion of the bore. Now, none of the units that I've personally rebuilt or repaired with my own two hands exhibited such problems, but that was 20 years ago. With more of these cars being resurrected from barns and fields, perhaps that work is more necessary these days, but I doubt if it has anything to do with a failure shortly after a professional rebuild.

Posted on: 2010/12/4 10:44

|

|||

|

||||

|

Re: Bendix Treadle Vac Study- Serioius Business!!

|

||||

|---|---|---|---|---|

|

Home away from home

|

BH wrote Quote:

(snip)I doubt if it has anything to do with a failure shortly after a professional rebuild. Ah, therein lies a big problem as far as my experience is concerned. NONE of my 4 BTV failures occurred shortly after a professional rebuild. A failure shortly after would be easy to find. All of mine occurred about 1 year after the rebuild (see the Kanter disc brake conversion thread for details). My 55 Pat was more or less continuously driven, i.e., it was not and is still not a trailer or garage queen. To me, this indicates an entirely different type of problem than wrong rebuild component or rebuilder incompetence. Craig

Posted on: 2010/12/4 12:43

|

|||

|

Nuke them from orbit, it's the only way to be sure! Ellen Ripley "Aliens"

Time flies like an arrow. Frui |

||||

|

||||

|

Re: Bendix Treadle Vac Study- Serioius Business!!

|

||||

|---|---|---|---|---|

|

Home away from home

|

All,

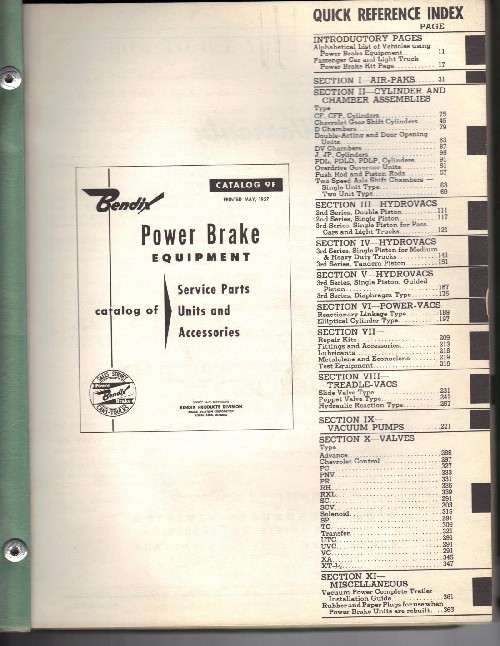

How does one properly identify models of these Treadle Vacs by Bendix? With all the 'conversation' going on within the forum, I decided to try and look further into the general situation myself too. I found some original Bendix literature from May 1957 through February 1958 and it covers all American marques as far as I can tell. It collectively is a tidy sum of pages and the more I go through it the more questions I seem to have. How does one tell if they have a poppet valve, hydraulic reaction or a slide valve type of BTV? The 'back-up' treadle vac I have out in the garage (removed from my '55 Patrician parts car)looks a bit differently on the outside them the unit I had rebuilt and is now in my 400. Further, given that partial failure I had with my BTV several months ago, I wonder how a technician would readily ID particular BTV units? The unit on my work bench has NO visible serial numbers that I can find. Of particular interest to me right now is the compensator valve issue. As I look at the literature, the BTV units I've listed above indicate that there are (2) different part numbers for compensator valves. The slide valve & hydraulic types carry a part number of 376177 for the valve, the poppet valve has a part number of 374915. I also find interesting that Bendix indicates that (2) separate BTV unit part numbers for 1955 Packards. They break out "early" & "late". The early BTV is part number 377141 & the late BTV is 377529. What makes one early & the other late. Is there a way to make such a determination by way of VIN's ? I just don't know!

Posted on: 2010/12/4 17:08

|

|||

|

||||

(174.61 KB)

(174.61 KB)