|

Re: pushbutton transmission

|

||||

|---|---|---|---|---|

|

Home away from home

|

John, just out of curiosity, how much do you charge for this service?

Posted on: 2007/5/6 19:38

|

|||

|

||||

|

Re: pushbutton transmission

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

$25/hr + parts and materials, $40 for the eight fingers, The average job is between $300 and $400

here are the videos on youtube: youtube.com/watch?v=S6nsZzGsiTs youtube.com/watch?v=6y1fiQnHBsU youtube.com/watch?v=7G9WC7AiFTM

Posted on: 2007/5/6 19:44

|

|||

|

||||

|

Re: pushbutton transmission

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

MrPushbutton -

The videos are cool, but your text and captioned still photos tell the real story. This has been the most informative stuff I've seen published on the system in decades!

Posted on: 2007/5/7 17:54

|

|||

|

||||

|

Re: pushbutton transmission

|

||||

|---|---|---|---|---|

|

Home away from home

|

Great pics. Beautiful job. What is "potting" the wires???? Why not just use new wire???

Posted on: 2007/5/7 22:14

|

|||

|

||||

|

Re: pushbutton transmission

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

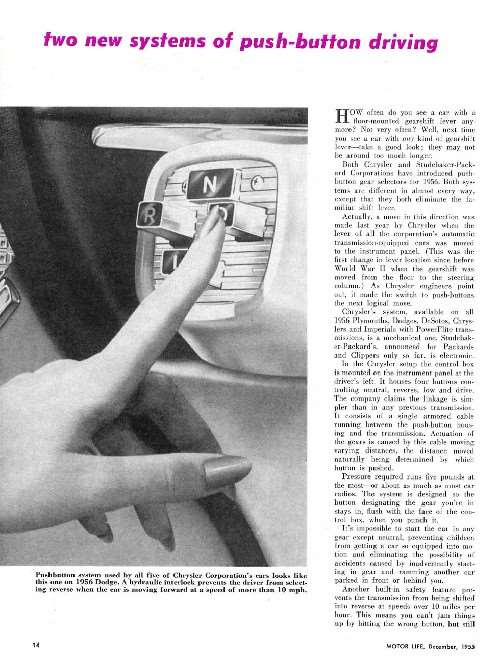

P-V8--"potting" is a term left over from my days in electronic manufacturing, it describes the process of molding a compound around an object. The reason I don't use new wire (yet) is that the pushbutton contact segment wires are cast into a rubber block (see pic. 16) as a seal to keep road dirt and water out.

A percentage (I'm guessing about a quarter) of the pushbutton units I'm seeing have this condition where there is a break in the insulation jacket right where the wire exits the rubber block, leaving about 1/16" of exposed wire. There will be 4-6 such exposed sections in the same harness, making me afraid that a loose piece of anything conductive could get up there and short out the leads, and cause trouble. I form a mold around the back side of the rubber block and encase those exposed sections of wire to avoid such problems. It's also good since it changes the bending point of the wire.

Posted on: 2007/5/8 6:38

|

|||

|

||||

|

Re: pushbutton transmission

|

||||

|---|---|---|---|---|

|

Home away from home

|

After a decade follows new input to dust off and revitalize this old but substantial thread.

Posted on: 2017/9/1 14:39

|

|||

|

The story of ZIS-110, ZIS-115, ZIL-111 & Chaika GAZ-13 on www.guscha.de

|

||||

|

||||

(36.22 KB)

(36.22 KB)