|

Re: Torsion Level Operational, or not?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks for the info, with which I can proceed. I don't think there is any load on the transverse bars, as I can easily rock them by hand. I should be able to remove the compensator and transverse bars for inspection.

I had replaced the compensator assy., limit switches and transverse bars with parts that I got from Mike Dillinski (sp) during my last TL fiasco. I might be able to use parts from my old compensator, if they are good.

Posted on: 2015/3/12 11:06

|

|||

|

Bob

IF EVERYTHING IS COMING YOUR WAY ... - - - - - - - - - - - - - - - - - - - - - - - - YOU'RE IN THE WRONG LANE! '56 Executive Touring Sedan |

||||

|

||||

|

Re: Torsion Level Operational, or not?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Since I must remove the compensator, I am feeling like I'm about to take a final exam in the TL class at Packard U. (PU?)

The last time I did this, I had help of a strong friend, who bullied his way to install the compensator and drag-link connections. He is not available to help and I need to finesse my way to graduation. The last time I did this, I had help of a strong friend, who bullied his way to install the compensator and drag-link connections. He is not available to help and I need to finesse my way to graduation.Is there a step-by-step procedure that takes into account things like: - Transverse bar ends too close to the frame to get the drag-link socket and ratchet on. - No clearance to remove the inner Transverse bar ends once the end caps are removed with the drag-link socket. - etc.

Posted on: 2015/3/12 21:31

|

|||

|

Bob

IF EVERYTHING IS COMING YOUR WAY ... - - - - - - - - - - - - - - - - - - - - - - - - YOU'RE IN THE WRONG LANE! '56 Executive Touring Sedan |

||||

|

||||

|

Re: Torsion Level Operational, or not?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Bob,

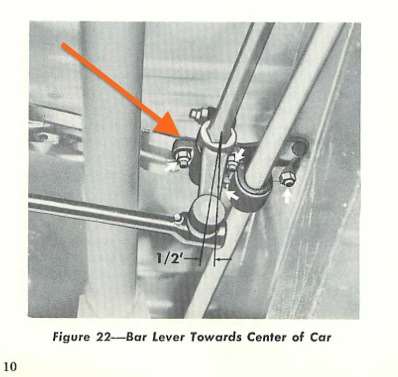

So your car is not like the service manual, (post #5 of this thread), page 10 figure 22, hopefully your bars are in similar geometry? If your gearbox is bad as you suggest, if you jack up the right or left side of the car, does that help get you the access you need?

Posted on: 2015/3/12 22:07

|

|||

|

||||

|

Re: Torsion Level Operational, or not?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

The components are as pictured, in their correct orientation. Lifting the car makes no difference in any of the TL components, but must be done to get access to work on any TL components. Things must be methodically undone in order to gain access to remove the next thing, kinda like one of those puzzle boxes. The same goes for re-installing the TL components. EDIT: All of this caution is necessary to avoid unleashing 'the TL beast'!

Posted on: 2015/3/12 22:28

|

|||

|

Bob

IF EVERYTHING IS COMING YOUR WAY ... - - - - - - - - - - - - - - - - - - - - - - - - YOU'RE IN THE WRONG LANE! '56 Executive Touring Sedan |

||||

|

||||

|

Re: Torsion Level Operational, or not?

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

It is going to take some work without the compensator. If the transverse bars are loose then the short bars should not be under any tension and the front bearing holding the ball arm and transverse bar end can be removed. I don't remember if the clamp holding the rubber vibration collar around the main bar will also come with the bearing plate bracket. If it does that won't affect anything.

Once the front bearing is loose that should allow the short bar to drop down a tiny bit so the plug is below the frame. Bar will still be clamped at the rear in the load arm so if it doesn't want to move down enough don't force it. With the bearing off another possibility is you may be able to loosen the clamp and slide or drive the ball arm off the short bar taking the transverse bar with it. If you do remove the arm off the bar make sure to use a dab of paint, tape or a marker on the arm and bar to make sure arm goes back on the hex at the same orientation. Downside to removing the bearing is once the bar is loose there is nothing to push against if the plug is well staked and doesn't want to budge. You might have to get creative. If that doesn't look like a viable option then the other thing that might work is to kind of follow the instructions in SM where they raise or lower the rear to centralize the bar in the bracket. You would have to do that by changing weight in the trunk or do what is needed in the trunk or at the rear axle to rotate and change the angle of the load arm so the short bar will rotate the ball arm toward the center. Attach file:  (21.65 KB) (21.65 KB)

Posted on: 2015/3/12 22:28

|

|||

|

Howard

|

||||

|

||||

|

Re: Torsion Level Operational, or not?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Howard, I had the same thoughts, but wanted a second opinion as to the removal of the short bar's bracket.

I have my old compensator taken apart and have a question. Does the ring-gear 15.947 actually turn during operation? (If it does turn, the one on my old unit is hard fixed to the bottom half of the case). I still need to remove and inspect the compensator that's on the car. I hope to do that soon. I'll follow the SM closely for removal and re-installation. I gotta get a passing grade on this final at PU

Posted on: 2015/3/14 13:17

|

|||

|

Bob

IF EVERYTHING IS COMING YOUR WAY ... - - - - - - - - - - - - - - - - - - - - - - - - YOU'RE IN THE WRONG LANE! '56 Executive Touring Sedan |

||||

|

||||

|

Re: Torsion Level Operational, or not?

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

No, the ring gear should not turn. That is part of the power transfer between the two sets of planetary gears so needs to be stationary. Some have had issues with the clamp bolts between the halves being loose allowing the ring to turn. That ring gear turning results in the same symptom you have -- motor runs but nothing happens.

Just make sure when you remove the end bearing that there is no load on the short bars. The transverse bars being loose should be a good indication there is not but when removing the bolts on the bearing bracket if something wants to put a lot of pressure and twist the bar or bracket as bolts are loosened then go slowly and reevaluate.

Posted on: 2015/3/14 13:28

|

|||

|

Howard

|

||||

|

||||

|

Re: Torsion Level Operational, or not?

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

OK, will do. I did notice something else, in the TL motor. When the armature was removed, I inspected the brushes and found that one side's spring was very weak if any at all. Is there a TL motor brush rebuild kit available?

Posted on: 2015/3/14 18:51

|

|||

|

Bob

IF EVERYTHING IS COMING YOUR WAY ... - - - - - - - - - - - - - - - - - - - - - - - - YOU'RE IN THE WRONG LANE! '56 Executive Touring Sedan |

||||

|

||||

|

Re: Torsion Level Operational, or not?

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I don't believe there is a brush kit exactly but the motor is a modified Delco generator so there should be plenty of parts available.

Posted on: 2015/3/14 20:42

|

|||

|

Howard

|

||||

|

||||