|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

OK, I found it. If the switch in post 358 is the one you are using it is original style and NOT polarity sensitive. Having said that, there is always the possibility one of the heater elements has burned out and it only works in one direction. That would have caused the car to raise or lower at some time and never return to level. The heaters failing and not being repairable was the reason the solid state reworks were conceived.

Posted on: 2016/1/29 11:14

|

|||

|

Howard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Home away from home

|

The two new solenoids I ordered should be here tomorrow of Tuesday. Hopefully will wrap up the T/L soon.

I took the engine heads into a local shop recently. They hot tanked them for me and did some "light duty" rework. They said there probably were not that many miles on them since the last rebuild. They replaced or added one valve guide, all the oil seals on the valve stems and 8 hardened value seats. All the rest of the valves and springs are still in use. It's not at all what I was expecting but I can't beat the price for now. Been examining the rocker arm assembly but have not done anything with them yet. Two of the push rod seats have sign of excessive wear. Oddly 14 of the push rods are identical. The last two have a different shape. How much you want to bet those two were on the worn rocker arms. All the other rocker arms look great but I am no expert on such things. I am at the very least playing to replace the two worn rocker arms. I have gone back and read a couple of my last post and I guess I need to slow down. I've been making all kinds of simple grammatical errors. Its most embarrassing.

Posted on: 2016/1/31 21:13

|

|||

|

Stewart Ballard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Home away from home

|

The fun continues.

The new solenoids arrived tonight. First thing I did was test them per the earlier test that Howard recommended. They behaved just like the original solenoids Packard solenoids. I hooked everything back as it is supposed to be but, no joy. The control box made a couple clicking sounds after about 10 seconds but the motor never responded and the solenoids never energized. Oddly (to me) I tested both sides of the limit switch and had 12 volts on both sides. I was not expecting to get anything as I was not holding the lever for the control box. Last week I was only getting 1.5 at the limit switch and that was only when I moved the level on the control box. Either I have done something differently or something has changed inside the control box. I tried both positive and negative ground.

Posted on: 2016/2/1 19:18

|

|||

|

Stewart Ballard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Hook the battery up as normal to have ground on the frame and connect the red fuse lead wire to provide the hot side power to the buss bar on the BAT side of solenoids. Don't bother with the control switch yet.

Use a small clip lead or jumper wire to touch between the frame and the buss bar or small terminal on a solenoid. The motor should drive. Test the other solenoid the same way and again the motor should drive the other direction. If solenoids don't come in or motor doesn't drive the problem is ground to motor or a high resistance connection somewhere. If those tests are good use the clip lead or jumper on the terminals on the other side of limit switch or at the control switch on the terminals either side of center. The motor should drive again. If it works on all of those the control switch needs to be examined to see what is happening. If the motor fails to drive at a point then the problem can be narrowed to what is between the go and fail.

Posted on: 2016/2/1 19:31

|

|||

|

Howard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Home away from home

|

Stewart- you are correct, the two push rods are the incorrect type. I have two rods and rockers if you need em you can hit me up. Looks like a lot of wear on the rocker flats.

Posted on: 2016/2/1 19:33

|

|||

|

[url=https://packardinfo.com/xoops/html/modules/

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Home away from home

|

I hooked up the power lead as normal and touched the ground to the small terminal of one solenoid and the motor turned. I then tried the other

and it turned the opposite direction. Then I disconnected the pink and yellow leads from the control box and touched the ground to each one separately and got the same results (motor movement in both directions). I stopped there for tonight as we have storms in the area and wanted to get back to the house before it got bad. When I get out there tomorrow night and reconnect the control box do I run a ground to the center terminal of the control box? Lastly I believe the limit switch may be having some issues. Since the solenoids are larger then the originals that causes the limit switch to set a little higher and closer to the bottom of the compensator. In fact I think it touches the compensator so its creating some friction and may not be returning to its neutral position.

Posted on: 2016/2/2 19:18

|

|||

|

Stewart Ballard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

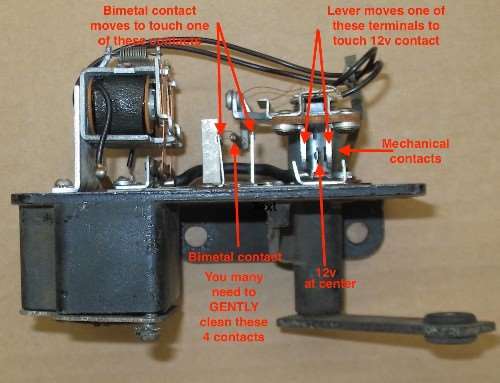

You need power to the center terminal of control switch. Ground is provided thru the case being bolted to the frame.

When you move the switch lever one direction it closes a mechanical contact and energizes one of the heaters to start bending its bimetallic strip. After about 7 seconds or so the bimetal will bend enough to touch another contact and bring in one of the relays. When the relay closes it connects a solenoid terminal to ground and motor starts going. Other things happen in the switch between the relay, heater, and bimetal contacts but that is not important for this description. The important part of what else happens is the relay will stay energized until the switch lever moves back to the center position and disconnects the first or mechanical contact. Moving the lever the opposite direction repeats the cycle with a different mechanical contact, heater, bimetal strip contact and relay to move the motor the other direction. The time delay is kind of arbitrary. Packard said 7 seconds but in reality it has been reported as low as maybe 5 and some have said theirs typically runs over 10 seconds. I suspect it has to do with the actual voltage the heaters are receiving. The limit switch does need to move freely. It may be possible to bend the actuator bar slightly to clear whatever it is touching but be careful. I don't remember if the actuator mounts to actual metal in the switch and can take some pressure or mounts to the fiber board holding the contacts.

Posted on: 2016/2/2 19:50

|

|||

|

Howard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Home away from home

|

I think I'm digging myself into a deeper hole.

Hooked everything up as normal. Ground to frame, power to solenoids and the center terminal of the control box. All I got was a couple clicks from the control box after about 6 seconds when I moved the lever toward the center of the frame. When I pulled it toward the outside it did nothing at all. No movement in the motor. As a test, I left the battery hooked up as it was and got out my multi-meter. I tested both sides of the limit switch and both small terminals were the limit switch connects and I had 12 volts in all 4 locations. Is that right? I thought the control box sent current there when the switch moved but what do I know.

Posted on: 2016/2/3 19:31

|

|||

|

Stewart Ballard

|

||||

|

||||

|

Re: Stewart's 1955 Packard 400

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Reading 12v to ground at the small solenoid terminal and limit switch would be OK. The reason it is reading is because you have 12v at the BAT side of solenoid which is connected to the coil inside the solenoid. You are reading the 12v thru the coil at all those places because they are connected together. That also confirms the limit switch is closed (as it should be). The problem now is there is something going on in the control switch and the relay is not energizing to connect a solenoid coil to ground.

I would take the cover off the switch and see what is happening or take the switch off the frame and check it out. You can work the switch on the bench with only the ground to the case and 12v connected to the center terminal. Moving the lever closes 12v to one of the mechanical side terminals. That provides voltage to one side of relay and starts a heater doing its thing. You should see the bimetal contact start moving slowly toward a side contact. If it does not move, a mechanical contact is not making or heater is most likely open -- AFAIK there is no DIY repair possible on heaters. If it moves then as the bimetal finally touches its side terminal the relay should close. Reversing the lever does the same thing with the heater and contacts on the other side. One likely problem is the contacts have oxidized -- particularly the bimetal sets which do the actual work of closing the circuit to the other side of relay coils. If you have some contact cleaner I would put some on a Q tip and clean all 4 of those contacts. If you have a contact burnisher you can GENTLY use that too. You may need both but with either method be very careful not to snag one of the thin wires to heaters or bend anything. The mechanical contacts have more pressure applied so are not as sensitive to oxidation but it wouldn't hurt to do those too.

Posted on: 2016/2/3 20:54

|

|||

|

Howard

|

||||

|

||||

(76.73 KB)

(76.73 KB)