|

Re: Engine rebuild, help!

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Ahh, yes I’ll be sure not to forget those when I put the flywheel back on.

Posted on: 2023/3/10 19:39

|

|||

|

||||

|

Re: Engine rebuild, help!

|

||||

|---|---|---|---|---|

|

Home away from home

|

Because the holes aren't evenly spaced, it's easier to put in the screws by hand without the locks to be sure it is aligned, then take them back out in pairs to put on the locks. It's easier of you have a short cut-off bolt to help hold in the flywheel while finding the whole pattern match.

Posted on: 2023/3/10 20:39

|

|||

|

||||

|

Re: Engine rebuild, help!

|

||||

|---|---|---|---|---|

|

Home away from home

|

Something I found out awhile back, and quite by accident. The aircraft grease monkeys send their torque wrenches out regularly to have them calibrated.

Posted on: 2023/3/11 6:42

|

|||

|

If you're not having fun, maybe it's your own damned fault.

|

||||

|

||||

|

Re: Engine rebuild, help!

|

||||

|---|---|---|---|---|

|

Home away from home

|

Who do they send them to? Who would do that for "regular folk with a Craftsman". I've wondered.

Posted on: 2023/3/11 10:14

|

|||

|

||||

|

Re: Engine rebuild, help!

|

||||

|---|---|---|---|---|

|

Home away from home

|

Like as not, these guys are putting the Snap-On salesman's kid through astrophysics school.

I wager that Google knows all the wrench calibrators. To me, the problematic part becomes the shipping, but then, what do I know???

Posted on: 2023/3/12 6:43

|

|||

|

If you're not having fun, maybe it's your own damned fault.

|

||||

|

||||

|

Re: Engine rebuild, help!

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

This is SOP at any place with actual manufacturing standards. Many places will buy calibration equipment for their tools, others will mail them out, and others will have a company that has all this stuff in a van drive out and calibrate all their tools. A quick Google Maps search for something like "calibration services" can often yield some results. Generally the schedule is once per year, though that assumes frequent use (a few thousand clicks per year). If you don't abuse torque wrenches by dropping them, and always store them at their lowest torque setting, and only use them a few times per month, then I would only check them like once or twice a decade, as the spring fatigue will be much slower. Though be aware that excessive dirt in the mechanism can also mess up the torque reading, so it's best to not get them very dirty. A quick test is to get some sockets to connect a newer and older torque wrench together, twist them against each other and see if they click at the same time.

Posted on: 2023/3/12 7:12

|

|||

|

1955 400 | Registry | Project Blog

1955 Clipper Deluxe | Registry | Project Blog 1955 Clipper Super Panama | Registry |

||||

|

||||

|

Re: Engine rebuild, help!

|

||||

|---|---|---|---|---|

|

Home away from home

|

I would also wager that if shop temperatures vary widely, then condensation would become an issue also. That would also be true for tools stored in truck tool bins/boxes.

Posted on: 2023/3/12 15:57

|

|||

|

If you're not having fun, maybe it's your own damned fault.

|

||||

|

||||

|

Re: Engine rebuild, help!

|

||||

|---|---|---|---|---|

|

Home away from home

|

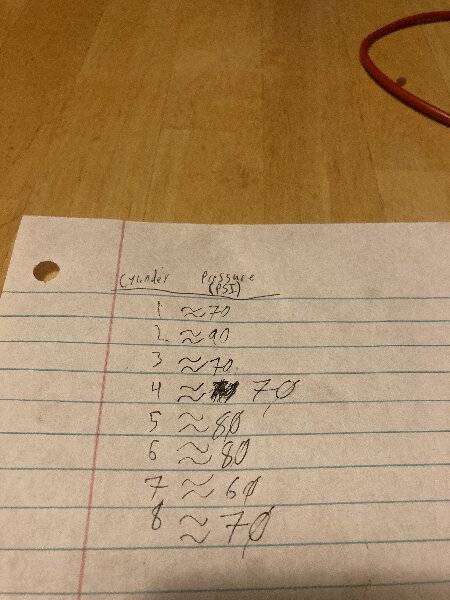

Hello all, I am once again having a little trouble, but first a little update.

Since my last post I have gotten my engine in the car, but unfortunately I made a silly Mistake and didn’t put the lifters back in the correct order and had zero compression on most cylinders, so unfortunately I needed to take it apart again. However, the first time around I somehow got away with rebuilding it in the living room but my parents weren’t too happy with that so that wasn’t an option so I decided to send it out to a machine shop and just pay to have them do all the work over again. I gave them my shop manual for all the clearances, torque specifications, etc. I got it back again and now have it in the car once again. Now I am having trouble starting. My first concern is that I have low compression on a few cylinders. I will attach a picture of my results (picture 1) the night before this test I put oil in the cylinders so this would be a wet test. I can tell the low compression is from blow by. My question is will this blow by go away once the rings seat? My second question- and main concern is timing. I am simply stumped as to what is going on with this. I set my engine so cylinder 1 is at 6 degrees before TDC of its compression stroke. (Picture 2) Then I ensure the distributor rotor is pointing to approximately the 7:30 position (picture 3) I then turn the engine over until the spark occurs and it is at approximately 90 degrees AFTER TDC. (Picture 4) Attach file:  IMG_2114.jpeg (170.75 KB) IMG_2114.jpeg (170.75 KB)  IMG_2106.jpeg (343.46 KB) IMG_2106.jpeg (343.46 KB)  IMG_2107.jpeg (302.97 KB) IMG_2107.jpeg (302.97 KB)  IMG_2111.jpeg (291.26 KB) IMG_2111.jpeg (291.26 KB)

Posted on: 2023/9/28 10:41

|

|||

|

||||

|

Re: Engine rebuild, help!

|

||||

|---|---|---|---|---|

|

Home away from home

|

Do I just need a new distributor? I have not replaced it yet, just the cap, coil, and plugs.

I will attach pictures of my points as well. Could it be that the machine shop installed the oil pump wrong?

Posted on: 2023/9/28 10:48

|

|||

|

||||