|

Re: Bits of brass in a 32 900 differential

|

||||

|---|---|---|---|---|

|

Home away from home

|

Tom,

I've used the sleeve option on other ball bearing before when a source was not available. I try to use a slightly smaller bearing so I don't have to modify the original casting. If the correct bearing is found, or made in the future it can be put back in. As long as the dynamic axial and radial load rating is equal or better than the original bearing you have, you should not have a problem. Did you mark the location of the spider X that is captured between the two housings? This is the part the four spider gears fit on. Also the two differential halves that capture the spider should have been marked so they would be re-assembled in the same location. If you didn't you may want to try different orientations to correct the bind in the spider gears. I don't think excess torque is you problem. Try removing all the spider gears and reassembling them one at a time. You don't need to full torque all the nuts. Check for free play as you assemble each gear and tighten, then loosen and add another in. The side gears the spiders mesh with, the ones the axle shafts fit into, should have been marked and re-installed in the same place they were originally. Any dirt, chips, etc. between these side gears will cause a bind in the spider gears because it will force the side gears against the spiders. I wouldn't worry about the mark on the I.D. bore of one of the spiders, as long as it is not a crack. These gears only turn at slow speeds to compensate for the difference in revolutions between the rt. and lft. wheels. Regards, Dave

Posted on: 2011/4/24 11:55

|

|||

|

||||

|

Re: Bits of brass in a 32 900 differential

|

||||

|---|---|---|---|---|

|

Home away from home

|

Dave,

I did mark the housings, but I did not mark the spider or the spider gears. I will try to re-orient the spider itself from the photo. As for the gears, hmm, there are only 24 possible combinations. Aaarg. Thanks for the help. Tom

Posted on: 2011/4/24 15:08

|

|||

|

||||

|

Re: Bits of brass in a 32 900 differential

|

||||

|---|---|---|---|---|

|

Home away from home

|

Tom,

When I took mine apart I just marked the orientation of the two housings and the X the spider gears ride on. I do remember the gears were snug after re-assemble, not free enough to turn by pushing on them by hand, but free enough to be rotated by holding one axle shaft and turning the other, by hand. Regards, Dave

Posted on: 2011/4/24 15:15

|

|||

|

||||

|

Re: Bits of brass in a 32 900 differential

|

||||

|---|---|---|---|---|

|

Home away from home

|

Tom,

It may help to go CSI on the carrier. I don't know if it's the same carrier you're working on now, but on the pictures you have at the Packard Paddock, I can see some marks on each side of the carrier that could be used to establish a pre-teardown orientation. If it's a different carrier maybe you have some pictures of the current carrier you can analyze. Regards, Dave

Posted on: 2011/4/24 15:32

|

|||

|

||||

|

Re: Bits of brass in a 32 900 differential

|

||||

|---|---|---|---|---|

|

Home away from home

|

Dave,

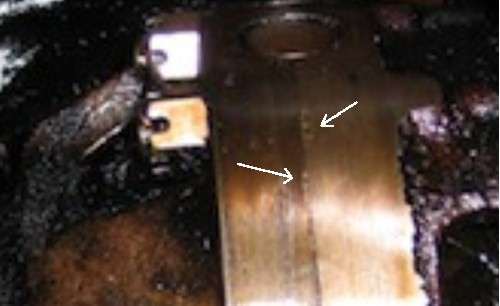

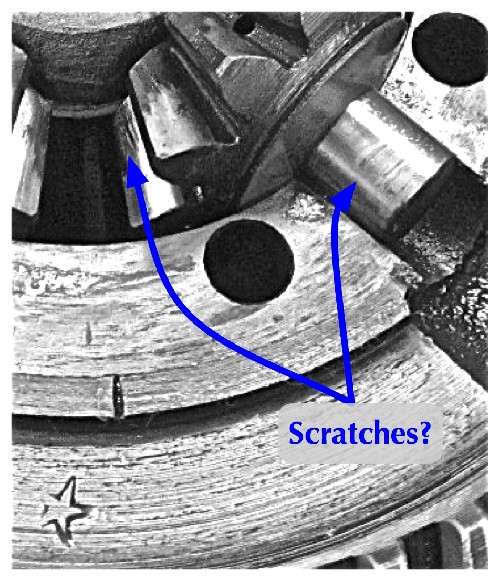

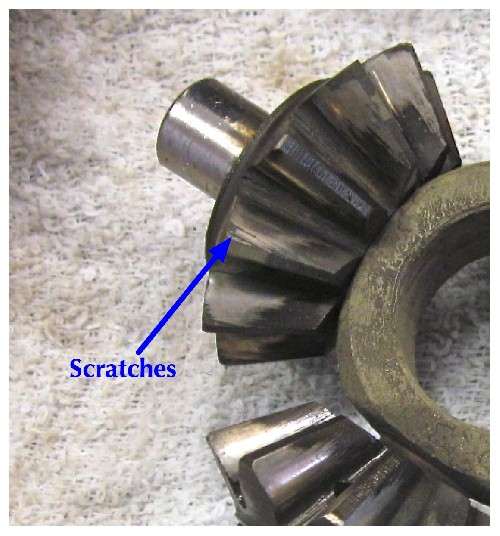

The orientation of the carrier is easy. It was already marked, see below. But, I did not mark the orientation of the spider in the carrier. There are some distinct scratches that I can see on the gears and maybe the spider, so that may help. All the pictures on the paddock website are from the 1930. I haven't updated the site in a long time, so there are no photos of the 32. One more thing I really need to get done. Again, thank you Dave and Dave for your help and patience. I will let y'all know if I figure it out. Tom

Posted on: 2011/4/24 15:51

|

|||

|

||||

|

Re: Bits of brass in a 32 900 differential

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Those Angleset differentials are so robust and overdesigned, I'd guess they'd outlast 5 engine rebuilds. I'd bet this one either ran low on lubricant or didn't have the lubricant changed regularly. Was neglect present in other aspects of the same car?

Posted on: 2011/4/24 17:32

|

|||

|

||||

|

Re: Bits of brass in a 32 900 differential

|

||||

|---|---|---|---|---|

|

Not too shy to talk

|

I've seen new spider gears that had similar "scratches" on them. It's really just sloppy (non-critical) machining. The ring & pinion are high precision gears, but as stated the side & spider gears turn much slower & so they weren't made "to look as pretty". Don't worry about it.

Posted on: 2011/4/25 21:45

|

|||

|

||||

|

Re: Bits of brass in a 32 900 differential

|

||||

|---|---|---|---|---|

|

Home away from home

|

Dear All,

Success! Using photos of the spider and spider gears taken during disassembly, I was able to figure out the original arrangement of gears and spider in the carrier. Putting everything back together in this arrangement solved the problem! The planetary gear system now spins quite easily in the carrier! Dave and ineffabill, I highlighted the scratches in the gears to show the sorts of marks that might let me deduce how the gears were originally placed in the carrier, not because I am worried about them. Thank you for your wonderful assistance. Tom p.s. I have not safety wired the fasteners yet. I will next time in the garage.

Posted on: 2011/4/26 9:29

|

|||

|

||||

|

Re: Bits of brass in a 32 900 differential

|

||||

|---|---|---|---|---|

|

Just popping in

|

Has anyone been able to locate the SKF I-70268 to replace the differential pinion bear (rear) on the 1932 900 or a satisfactory work around?

Posted on: 2023/10/24 13:53

|

|||

|

||||

(32.44 KB)

(32.44 KB)