|

Re: maximum wear for 356 valve stems?

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Thanks for all the info. Not sure when I will be able to remove the guides but I like that option better than the bushings. Now I have to do this without offending the guy that was going to install the bushings. He is a really good guy and has helped me a lot.

I was thinking that reaming out worn guides and having the hole line up with the valve seat would be a problem too. Got the impression that the seats would be ground using the new hole center. Maybe alright if the hole isn't too far off to one side. Next question: Where is the best place to buy replacement guides? I really want to stay away from the Chinese stuff if at all possible.

Posted on: 2011/12/4 12:13

|

|||

|

||||

|

Re: maximum wear for 356 valve stems?

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Kanter, Max, etc. all would have them. Whether they all come from the same source I don't know. I've usually bought mine from Egge, ditto for the valves, but the last set I believe was bought from Kanter for a 1938 Eight (120) and the fit just fine. Still, if I'm also buying valves I'd be more comfortable buying both guides and valves from the same source. Try Egge first. And sure, use the newly installed guide to face off the seats.

Does your friend have a power valve seat grinder? Not that it will necessarily be needed - depends on the condition of the seats. A simple old-time method for final checking before installing the springs etc. was to use a soft pencil and make a series of radial lines across the valve face and then rotate the valve by hand, checking to see that all lines were equally broken and that the contact face width was reasonable (within specs). If the contact face is too narrow it should be widened (few more seconds with the seat facing stone). If it's too wide, the seat needs to be narrowed using stones of different angles. Probably could do just as well with Prussian Blue as with a soft pencil, but doing this gives great peace of mine before staring to reassemble.

Posted on: 2011/12/4 12:18

|

|||

|

||||

|

Re: maximum wear for 356 valve stems?

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Thanks Owen,

Just read your last post. Thanks for the dimensions. I have a machinist friend who can make that for me. I'm not where I can look at the guides in the engine right now but I think I remember that the guides are tapered at the top to a fairly sharp top edge. In other words they don't have a very wide flat surface, if any, at the top for the tool to drive against. Probably won't matter. Do you have the dimensions for the valve stem height adjustment tool? I could probably have that made as well as a driver that has a shoulder on it for setting the depth of the guide in the block. Looks like it may take two of those. One for intake and one for exhaust.

Posted on: 2011/12/4 12:33

|

|||

|

||||

|

Re: maximum wear for 356 valve stems?

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Quote:

A simple old-time method for final checking before installing the springs etc. was to use a soft pencil and make a series of radial lines across the valve face and then rotate the valve by hand, checking to see that all lines were equally broken Good idea. I was aware of using prussian blue too. One time I watched a machinist slap the newly ground valve and seat together and put a little liquid on top and blow air from the bottom watching for air bubbles. Don't remember what the liquid was.

Posted on: 2011/12/4 12:41

|

|||

|

||||

|

Re: maximum wear for 356 valve stems?

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

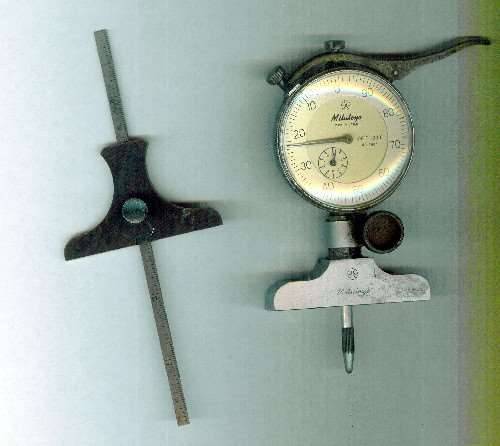

I don't use anything specific to Packard for measuring the depth that the guide is driven in, just an ordinary and basic machinist's depth gauge (ruler with adjustable "tee" top, do you need a picture?). As long as you'll also be using new valves, exact precision isn't needed but I'd try to be within 1/32 or thereabouts. Should you change any intake guides, remember that in some Packard engines they are driven in to a different depth.

The top face of the guide should be sufficiently flat to nicely engage the flat step on the driver. Sounds like you've been around a couple of valve jobs if not doing it yourself - that'll be good experience. EDIT: Here's some typical tools you could use to measure the depth of the guide from the cylinder block surface. The precision that the dial indicator offers certainly isn't needed, the little Tee-square gauge is has more than enough accuracy.

Posted on: 2011/12/4 12:53

|

|||

|

||||

|

Re: maximum wear for 356 valve stems?

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Owen, Made a tool and was able to drive out one of the guides. One problem: The guide drove down and into the bore for the lifter and is now loose how ever can not get it out of the block. Note: I did remove the cam and all the lifters. I was unaware that once the guide was driven out you still couldn't get it out the side.

What now? Now that the guide is loose and not partially still in its boar I am afraid to try and break it with a chisel. Don't want to damage the bore where the lifter rides. I suspect that with the 51 motor the lifter diameter where it passes through the block is smaller than on older engines. Think I remember seeing two different lifter diameters. If it were the larger of the two there probably wouldn't be a problem.

Posted on: 2011/12/10 14:40

|

|||

|

||||

|

Re: maximum wear for 356 valve stems?

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

If you removed the cam and lifters you should be able to drive the guide in one piece down and out thru the lifter bore; that's what the shop manual shows and that's how I did my 356 and have helped others similarly with theirs. You do not get the guide out thru the side. Have you browsed the shop manual for illustrations?

How about a picture? Saw your PM, I'll give you a call.

Posted on: 2011/12/10 16:08

|

|||

|

||||

|

Re: maximum wear for 356 valve stems?

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Quote:

If you removed the cam and lifters you should be able to drive the guide in one piece down and out thru the lifter bore; that's what the shop manual shows and that's how I did my 356 and have helped others similarly with theirs. You do not get the guide out thru the side. Have you browsed the shop manual for illustrations? Owen, It won't drive through the lifter bore hole. A lifter measures .623" the guide measures .633" The bottom .6" of the guide is smaller and measures .568". The bottom .6 inches does go right into the lifter bore but the main part of the guide that measures .633 will not. With the small end of the guide down in the lifter bore you can not pull the guide up far enough to then tip it to the side and then out. Too much of the small end of the guide is still down in the lifter bore. Does that make since? I did read the shop manual and it does say " with the cam and lifters removed the guides should just come out. They do not. I just did raise the guide up as far as I could and inserted the tapered top end back into the guide bore and wacked the thing with a hammer. The top tapered end snapped off. About 1/8 inch of it. Then it would come out. Maybe at one time the guides were replaced with ones that were a bit longer than they should have been. Maybe on the 356 the guides and or lifter bores are different than the 51-327.

Posted on: 2011/12/10 16:26

|

|||

|

||||

|

Re: maximum wear for 356 valve stems?

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Quote:

You do not get the guide out thru the side. The book doesn't really say wether they come out the bottom or out the side. Just know that the guide will not go through the lifter bore.

Posted on: 2011/12/10 16:30

|

|||

|

||||

(90.28 KB)

(90.28 KB)