|

Re: stop light switch 56 pat

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Your logic is correct. This is a common failure with the switch--particularly if it's been around silicone fluid. NOS available but pricy. There's a VW replacement some have had luck with (113945515G) that has different terminals--blade vs the round bullet type--so if you have blades, perhaps someone has already switched.

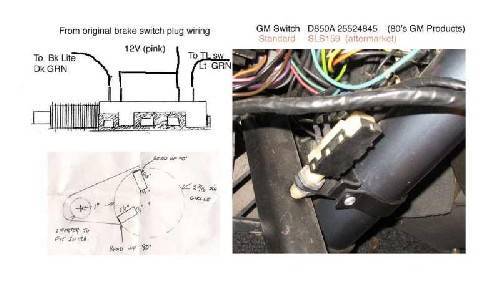

Another option is to convert to full mechanical operated by brake pedal. The picture shows one method of mounting and the parts I used. Mr. Berger sourced the Standard aftermarket switch at his local parts store.

Posted on: 2007/10/23 21:19

|

|||

|

||||

|

Re: stop light switch 56 pat

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks for the quick reply. ?, does the mech sw you used have 2 sets of contacts, 1 n/o and the other n/c. It looks like you have the 12v pink supplying power to both sets of contacts. I found Someone had wrapped the dk. green (stop light)around the 12v purple and the brake lights stayed on all of the time indicating the switch is defective or wrong type with no contact between those 2 terms on the switch. however the contacts on the switch do make and break for the LT grn. and the 12v pwr to the T/L. The switch is a replacement, Wells RB402. Apparently the OEM packard had 2 sets of contacts and the wells has only 1 (for the T/L). Ihe Packard shop manual or elect dwgs show the contacts and the parts manual doesn't mention it at all so I"m just guessing as to how the oem sw. worked. I'll try the local parts for the VW SW. you referenced.

Posted on: 2007/10/24 8:58

|

|||

|

||||

|

Re: stop light switch 56 pat

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

The original switch had one circuit with the common lead and normally closed going to TL and normally open to the brakes. When pressure applied the contacts reversed. The mechanical has 2 separate switches thus the need for pink wire to both ends. Since it is mounted with button pressed it is now "actuated" in normal operation so the logic is reversed with the normally closed to brakes and normally open to TL.

Posted on: 2007/10/24 9:16

|

|||

|

||||

|

Re: stop light switch 56 pat

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

It sounds as though you already have the VW switch. Double check the contacts with all but the hot lead removed. If the contacts work properly then just hook up the wires acccordingly.

Posted on: 2007/10/24 10:19

|

|||

|

||||

|

Re: stop light switch 56 pat

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks again HH56 and Randy B.

UPdate: It sounds like the switch circuit should work pretty much as I figured. I tried about everything I can think of, but no matter what I tried the results were the same, the common and N/C contacts (T/L)open with about 40psi but the other terminal (dk green wire)remains the same and has no power to the brake Lt. I even increased the pressure to about 70 psi but still no change. I tried all of the three wires on different terminals but that one terminal does nothing. If I wired the brake (dk.grn) to the N/C terminal, Pink to Common, Lt green to the third term, then the brake Lt's work but the T/L won't. I went to my local napa and will have another sw tomorrow or Fri. I"ll try again and let you know results.

Posted on: 2007/10/24 12:19

|

|||

|

||||

|

Re: stop light switch 56 pat

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Just curious about how you are trying to activate switch. You mention 40 & 70 lbs. One of the power brake sites mentions drums need 750 lbs minimum to stop, discs 1500 and list specs on their various units all the way to 2500 lbs so 70 might not be quite enough to do anything.

Posted on: 2007/10/24 19:38

|

|||

|

||||

|

Re: stop light switch 56 pat

|

||||

|---|---|---|---|---|

|

Home away from home

|

I use my air compressor. I did the test with the switch not installed in the brake line. I just screw the 1/8" threaded male sw conn into the air gun I use for blowing away dirt, etc. connect a ohmmeter or conductivity light to the common and N/C contacts and then adjust the pressure until the switch activates.

I found the wells RB402 brake switch will activate the N/C T/L contacts at about 38 to 40 psig, causing them to become open. I then connected the wires to the switch, 12v (pink) to common (center term), LT Grn to right term, Dk Grn to left term. I then presured to 40 psig, thereby killing power to the T/L switch. I figured the other terminal contacts for the brake lights should activate at the same pressure, but there was no change "no power to DK. Green wire to the brake lights", so I increased the pressure incremetally "about 5lbs at a time, didn't want to blow the diaphragm" until I reached 70 or 75 lbs, still no power to the dk grn wire. I moved all 3 wires to different terminals but, I never could get term 3 (left)to change status with the common or the N/C term which makes me believe the switch is faulty. I don't know how they calculate the pressure it takes to stop the vehicle but, I'm sure the equation includes mechanical aspects such as shoe or rotor size,etc. Anyway, I'll check it when I get the new switch and let you know the results.

Posted on: 2007/10/25 11:47

|

|||

|

||||

|

Re: stop light switch 56 pat

|

||||

|---|---|---|---|---|

|

Home away from home

|

Update: The brake lights and T/L are now working correctly. The correct wiring to the switch terminals is (looking at the termianl end, left to right) term 1, dk grn wire "brake light", term 2 (center term), Lt grn wire "T/L", term 3 purple or pink "12volt feed" The brake switch contacts (1) will activate (close)at about 80 to 85 psig, closing the circiut to term 3.

The shop manual is very unclear about how to correctly wire the switch. Thanks for your help and input. Next project, Fuel gauge problem.

Posted on: 2007/10/27 23:01

|

|||

|

||||

|

Re: stop light switch 56 pat

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

With all due respect, aren't you describing the VW switch with the spade terminals? The wiring diagram in the shop manual is correct. P stands for Purple. Pink wire is spelled out "PINK". The wiring as shown is correct for the Packard stoplight switch. The VW switch is apparently set up differently and it is good to know that. Just wanted to clarify that fine point.

Posted on: 2007/10/27 23:51

|

|||

|

||||

(33.92 KB)

(33.92 KB)