|

Re: 1937 120 Conv. Sedan - Blanche

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Quote:

With the sealed beams, I guess the Park lights up front are hidden until I add as fog lights or something? If this is the car where the original parking light bulb and location inside the enclosure was converted to accommodate turn signals I am curious how those bulbs are able to be seen or how mounting was done and still let you have a sealed beam conversion. Are your sealed beams the original type 7" diameter bulb used in that era which fills the entire surface of the housing?

Posted on: 4/12 19:32

|

|||

|

Howard

|

||||

|

||||

|

Re: LED brake light/turn signal bar

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

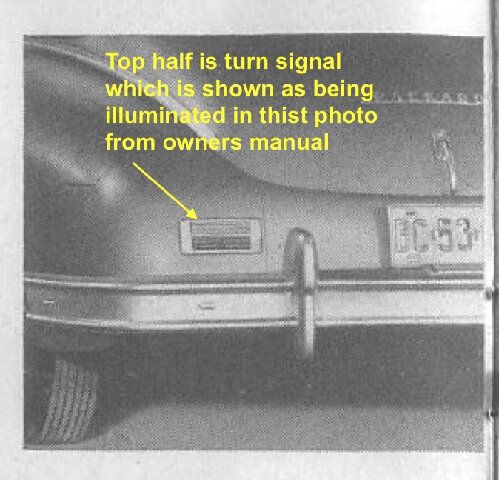

Has anyone with the two bulb tail light housings which use the separate turn signal bulb switched to LEDs? If so was it a noticeable improvement? 41-2 conventional and the Clipper based cars thru 22nd series used this two bulb arrangement. While the single LED bulb in the 23rd series housing doing both functions is quite nice, am curious on earlier cars with the dual bulbs if the turn signal flashing above the brake light could still be seen very well if the much brighter brake light was on. With incandescent bulbs the turn signal is visible in daylight but IMO, a bit weak.

The photo is of a Clipper thru 22nd series car with the horizontal split housing and shared lens.

Posted on: 4/12 10:46

|

|||

|

Howard

|

||||

|

||||

|

Re: Packard takes a swim

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Quote:

I can back up both my cars under power with the parking brake on, but I can't get either to move forward under power with it on. Very much too bad. Assuming he did set the emergency brake, maybe he needs to follow the procedure Ross suggests when adjusting his brakes. I think the one on Amelia island was an earlier model. Either it rolled off a trailer or was parked on an incline but it did find a lake. As to being able to move with emergency brake on in reverse, that describes perfectly the joys of the self energizing Bendix brake system. One of the selling points Packard mentioned is forward rotation causes the primary shoe to rotate slightly pushing the secondary hard against the anchor and causing it to wedge against the drum more tightly thus increasing braking force. You would think it would work in the opposite direction with the primary shoe against the anchor and wedging the drum but I can assure you it does not. Let me just say you have not had excitement in your life until you are riding in a car with a BTV and engine stalls while you are out for a leisurely drive going up a mountain road. A friend was driving and when the engine quit and car started rolling back he was pushing with all his might -- literally standing on the pedal and he was not a small man. The car barely slowed down as it rolled backwards. If there had not been a mountain on one side he could steer into I have no doubts we would have quickly seen the bottom of a canyon up close.

Posted on: 4/11 15:49

|

|||

|

Howard

|

||||

|

||||

|

Re: Light Bulb Designation, Vendors that Sell

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Quote:

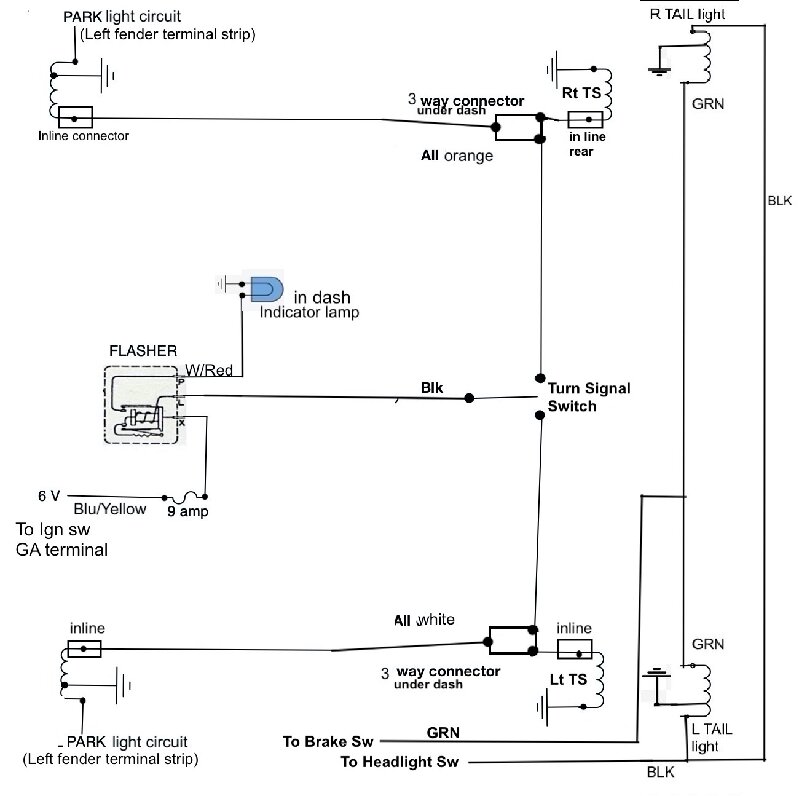

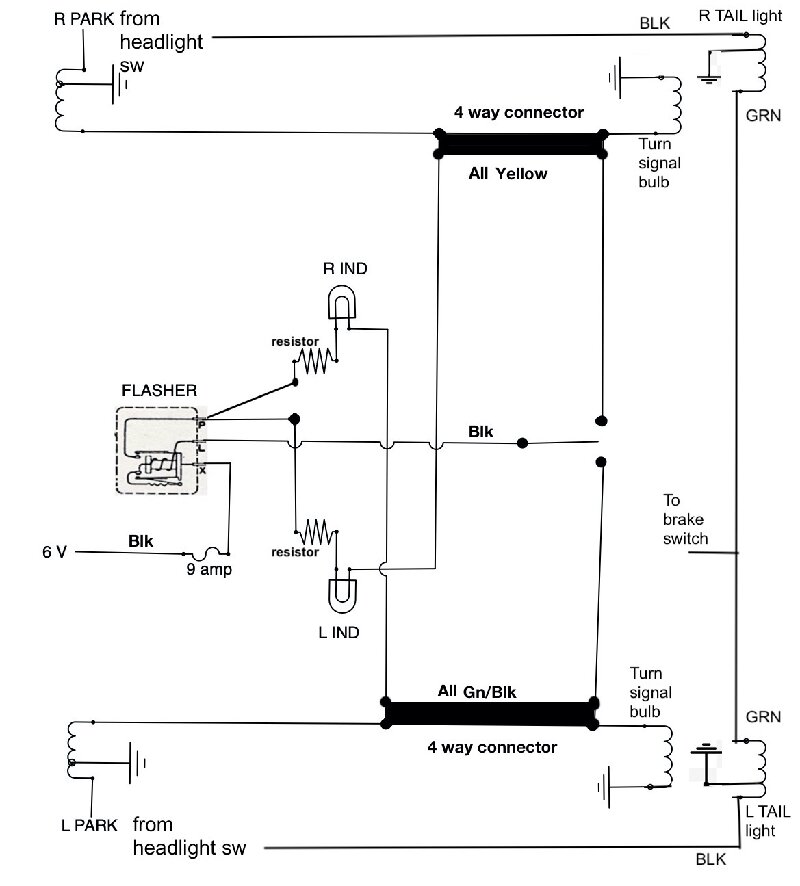

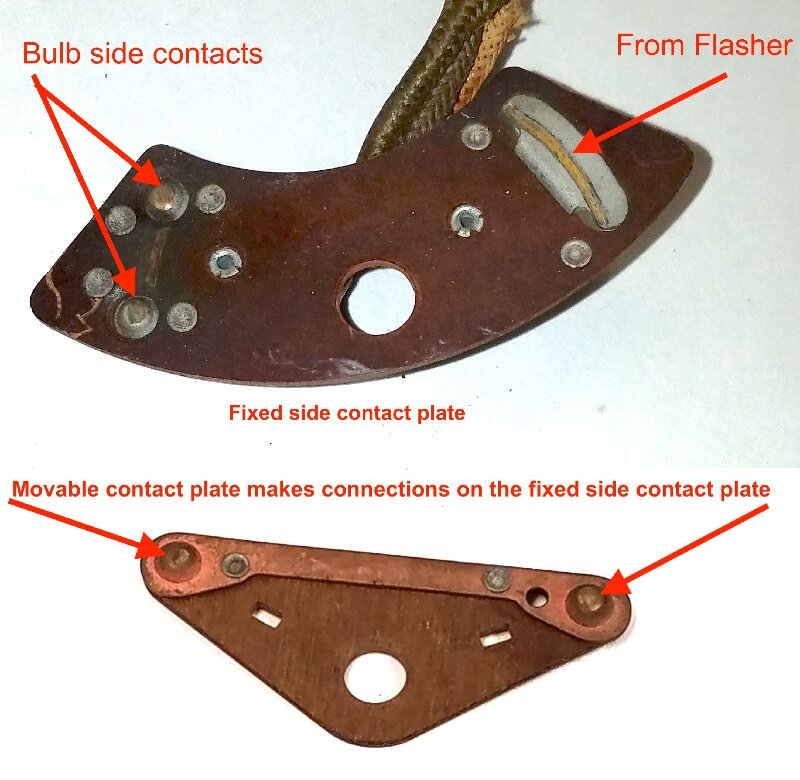

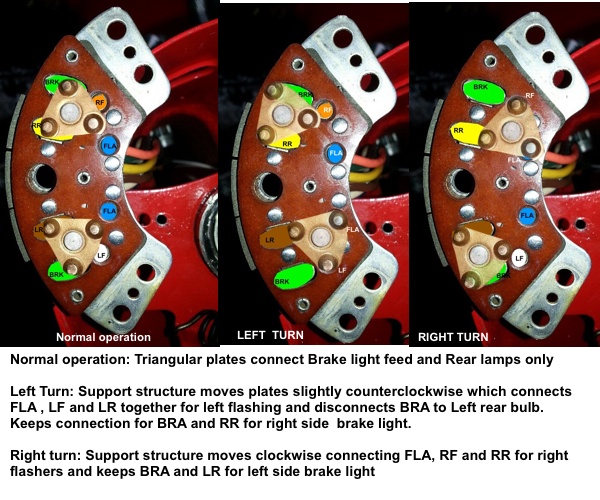

Front park and turn signal did share the same bulb but used separate filaments. Power from either the turn signal sw or parking light could go to the same bulb. The 40 and 41 wiring diagrams show the wires to the large filament taped off but present for further use. Prewar factory turn signal installs used the same 3 wire turn signal switch as did models thru the 22nd series. That switch is simply a single pole double throw switch so has no provision for separating voltage coming from the turn signal sw or the brake light sw. With brakes applied and both rear bulb filaments in parallel, if the turn signal was trying to flash one side, the solid on brake light power would take precedence and light both bulbs so flashing would not be seen. A separate bulb is needed in the rear for turn signals in cars thru the 22nd series and there are one and two bulb housings -- at least for the Clippers and 22nd series. Wiring shows senior 41 models might have the rear turn signal wire provision and there are different housings listed but my wire diagram is too poor a quality to follow path and see where the wires end. In the 23rd series they went to a 6 wire switch which was the same one used thru 54. When you move the lever on that switch, turn signal flasher is connected to both front and rear bulbs which start flashing while the brake light is disconnected from the side that needs to flash and is sent only to the other side thus lighting a single bulb. By disconnecting the brake light signal a single filament can be shared.

Posted on: 4/11 15:24

|

|||

|

Howard

|

||||

|

||||

|

Re: KPack's 1954 Panama

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Just my

, I think if you wind up needing to repair it again drilling a couple of holes in the flat wide surface of the clip will let some of the JB Weld squeeze thru the holes and sort of lock the clip to the ring. Clip would be able to take more shear or pull force which is kind of what the clip needs to withstand. , I think if you wind up needing to repair it again drilling a couple of holes in the flat wide surface of the clip will let some of the JB Weld squeeze thru the holes and sort of lock the clip to the ring. Clip would be able to take more shear or pull force which is kind of what the clip needs to withstand.

Posted on: 4/11 10:23

|

|||

|

Howard

|

||||

|

||||

|

Re: Light Bulb Designation, Vendors that Sell

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

There is an older thread which has info on 23rd series bulb or tail light housing removal. It might give you some information because for things like that Chiltons and Motors manuals are not much help.

As to the brake lights not working, almost all the issues others have had seem to have been due to a failed brake light switch so you might start there. The switch is located at the end of the master cylinder and is powered at all times from a circuit breaker on the back of the instrument cluster. The 23rd series 49-50 cars were the first Packards to share the same rear bulb filament for brakes and turnsignals. If you have turn signals that work then the brake switch is most likely at fault but since the wire from the brake switch goes thru the turn signal switch it could also be a bad or dirty contact in that switch or in the round plug between the loom and short bunch of wires coming out of the steering column right under the dash edge. Bad grounds caused by rust on the body sheetmetal or corrosion in the pot metal housing where the mounting studs make electrical contact with the body and housing are well known issues on almost all postwar Packards. On the 1154 and 1158 bulbs, if you look at the details they both have the same 3-21 candlepower rating but numbers are reversed so I suspect the difference must be how the side pins are positioned to orient the bulbs in the socket.

Posted on: 4/10 20:31

|

|||

|

Howard

|

||||

|

||||

|

Re: hph's 400

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Except for the front fender pieces and I think the little piece next to the side light the stainless "Reynolds wrap" is mostly held by being sort of clamped between the body and the upper and lower side strips. The strips use a combination of spring and stud/nut clips to hold them on. In addition to the side strips, The Four Hundred script helps hold one front fender piece in position and parking light the other. Been lots of years since I had one apart but seem to recall some small notches on each edge of the door piece where the clips which hold the side strips are located. The notches help keep it from sliding. The parts items you mention may be what is holding the small piece next to the light.

Posted on: 4/10 20:12

|

|||

|

Howard

|

||||

|

||||

|

Re: RIk's 56 ultramatic

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

That is a 54 only motor and relay box which had a two relays in the enclosure used for reversing instead of the separate but oppositely wound field coils most of the postwar Packard reversible motors thru 56 had. I think it might have been sourced from Autolite. Don't remember ever seeing one up close and have not been able to find a Packard wire diagram for that optional all electric seat. It would be 6v so I would consider that setup to be relatively rare. Some Ford products used the same motor/relay setup for both seats and windows.

Posted on: 4/10 19:38

|

|||

|

Howard

|

||||

|

||||

|

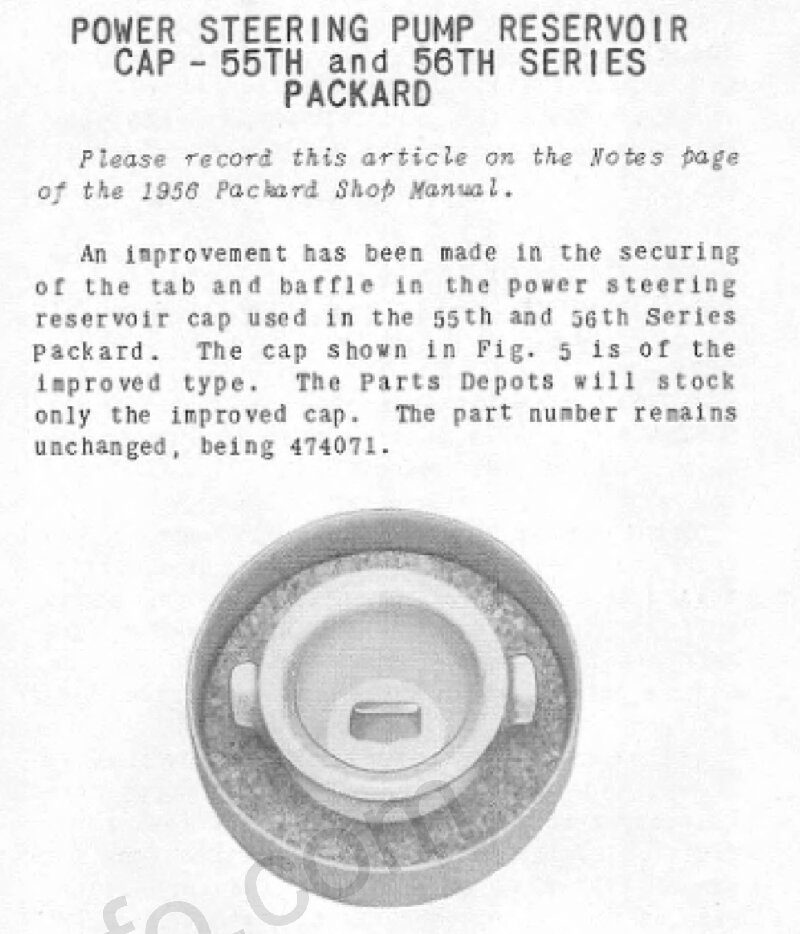

Re: PS Cap Gasket

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I've never tried it but if you have the new style cap wonder if you could sort of make a gentle bend and twist in the gasket to elongate the hole to a more oval shape and starting on one side work it over the center piece and around. Doesn't look like the hole is very big and cork doesn't stretch but it must have been doable if a replacement gasket was available. If you have the old style cap with the dipstick then you would probably need to remove the dipstick. I couldn't tell if the center piece was pressed over the tab or spot welded in but maybe you could. If pressed and could be removed and reattached, maybe that is how it could be done.

If spot welded I doubt if the gasket was in position when the center piece was installed during mfg but guess it was possible. If making the hole more oval won't work and the gasket was installed later and is cemented in, I wonder if there was a slit in the old one and that is how it was done.

Posted on: 4/10 17:08

|

|||

|

Howard

|

||||

|

||||

48 22nd series turn signal, brake and tail light.jpg (176.90 KB)

48 22nd series turn signal, brake and tail light.jpg (176.90 KB)