|

1955 1956 ignition bezel reproduction update

|

||||

|---|---|---|---|---|

|

Home away from home

|

Hi all,

Just a quick update on this project. I received 7 orders. I need 3 more orders to proceed and a sample. If we can't get a pristine sample, I can take any sample and duplicate it in CAD and proceed that way. If I draw it in CAD I can potentially beef up the problem areas where the springs connect and prevent future failures. Here's the link to the pre-order page: whiteglovecollection.com/shop/1955-1956-packard-ignition-bezel-preorder/ Thanks, Crin

Posted on: 2022/8/27 9:42

|

|||

|

||||

|

Re: 1955 1956 ignition bezel reproduction update

|

||||

|---|---|---|---|---|

|

Home away from home

|

Would the blueprints help with this project?

Posted on: 2022/8/27 10:03

|

|||

|

||||

|

Re: 1955 1956 ignition bezel reproduction update

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

R.H already mentioned the close fit so my thoughts on strengthening the problem area are unless you might be able to cast them from a stronger metal any beefing up may not fly. Originals appear to be whatever the common pot metal formula of the time might have been. While it is fairly strong, metal is also very brittle.

There is not a lot of room to make changes to the bezel. It needs to fit thru a fairly close tolerance hole in the dash so because of that the outer circumference cannot get any larger. The ignition switch is also a fairly tight fit within the inside circumference so it cannot grow in that direction either. Failure mode appears to be once the spring pressure starts bending the tab outward it slowly progresses. If you are lucky enough to find one bent but not completely broken off attempts to straighten the weakened tab usually result in them breaking off anyway. Here are a few photos showing the assembly. I made a duplicate of the dash hole when developing a repair kit that did work but is fairly hard to install so is not really a viable option. NOTE: I just realized the plate showing the dash hole was flipped when taking the photos. Obviously the bezel fits either way. The bottom notch keeps the bezel from rotating but in reality I have shown the upper notch for the light path on the wrong side. It should be on the right and under the bracket on the switch that holds the light socket. Attach file:  IMG_0253.jpeg (160.10 KB) IMG_0253.jpeg (160.10 KB)  IMG_0311.jpeg (75.67 KB) IMG_0311.jpeg (75.67 KB)  IMG_2573.jpeg (85.39 KB) IMG_2573.jpeg (85.39 KB)  IMG_2574.jpeg (59.92 KB) IMG_2574.jpeg (59.92 KB)

Posted on: 2022/8/27 10:26

|

|||

|

Howard

|

||||

|

||||

|

Re: 1955 1956 ignition bezel reproduction update

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Yes. Absolutely. If you have one I can look at that would be awesome.

Posted on: 2022/8/27 10:44

|

|||

|

||||

|

Re: 1955 1956 ignition bezel reproduction update

|

||||

|---|---|---|---|---|

|

Home away from home

|

Regarding beefing it up, I was thinking of adding more material in the direction of the red arrow. That would increase the resistance to the bending moment applied by the spring at the failure point (yellow arrow).

Looks like that would be viable since the spring fits over that end of the bezel and adding material in that direction would not be in the way of anything.

Posted on: 2022/8/27 11:08

|

|||

|

||||

|

Re: 1955 1956 ignition bezel reproduction update

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

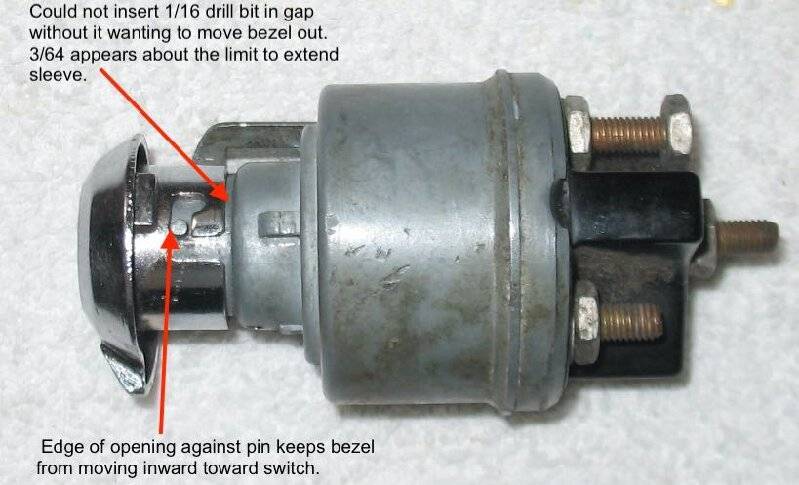

Every little bit of strength would help but it would appear there is not much room to extend the sleeve and that is assuming the switches are consistent.

In this photo the flat part of the bezel opening against the ign switch pins keeps bezel from moving in farther. Trying to insert a 1/16 drill bit in the remaining gap just barely wants to move the bezel outward. I would think 3/64 would be about the limit you could lengthen it and again that is presuming there is not much variation in switches.

Posted on: 2022/8/27 11:40

|

|||

|

Howard

|

||||

|

||||

|

Re: 1955 1956 ignition bezel reproduction update

|

||||

|---|---|---|---|---|

|

Home away from home

|

OK I see now. Scratch that idea...

Posted on: 2022/8/27 12:01

|

|||

|

||||

|

Re: 1955 1956 ignition bezel reproduction update

|

||||

|---|---|---|---|---|

|

Home away from home

|

I don't think this is going to make it to production. I have refunded the 7 orders. We'll try again on something else in the future. Thank you all.

Posted on: 2022/8/27 14:34

|

|||

|

||||

|

Re: 1955 1956 ignition bezel reproduction update

|

||||

|---|---|---|---|---|

|

Home away from home

|

I'm sorry to hear that you are giving up on this as I believe it is a very viable project that is much in need. The originals have lasted for over 60 years for the most part so a reproduction cast properly would extend the life at least that much! However, maybe CNC machining it from solid stainless would be better.

Posted on: 2022/8/27 14:46

|

|||

|

All generalities are false.

Once I thought I was wrong but I was mistaken. Don Pierson Packard / IMPERIAL page CA DMV Licensed Vehicle VIN Verification 1951 Henney-Packard 3-Door Long Wheelbase Air Force Ambulance The 1951 Henney-Packard is For Sale! 1954 Packard Patrician 1954 Packard Patrician Parts Car 1956 Clipper Custom Sedan |

||||

|

||||

Screenshot_20220827-120437_Gallery.jpg (83.81 KB)

Screenshot_20220827-120437_Gallery.jpg (83.81 KB)