|

Re: Adjusting 32's horns

|

||||

|---|---|---|---|---|

|

Home away from home

|

Tbirdman,

My experience has been with external mounted Sparton horns. You can adjust them for a sweet tone. The Sparton horns have a set of points that can be adjusted to control the movement of the spring steel diaphragm in the horn. There is a small clearance between the iron core connected to the spring steel diaphragm and the iron armature surrounding the core. The iron armature surrounding the core has the copper field windings that drive the iron core up and down as the horn is energized. Adjusting the points will increase or decrease the movement of the iron core and the horn diaphragm, which will change the horn tone and loudness. A few things can happen to turn the horn cormorant song into a duck quack; 1. The points have corrosion on them, preventing full movement of the diaphragm. 2. Corrosion can build up between the solenoid and armature, also preventing full movement, but also dampening movement of the diaphragm. Instead of a pure tone that resonates, you get a short tone that doesn't sound quit right. 3. The brackets holding the horns to the radiator shell have multiple thin strips of spring steel in them. Over time these strips either corrode away, or corrode together. The purpose of these is to isolate the horns from the rest of the car, so the horn vibration doesn't transfer and the horn assembly is allowed movement. Classic and Exotic in Michigan has a similar one listed on their site. They also have some other good Packard stuff..... 4. The thin spring steel diaphragm is rusty, cracked or has rust holes in it. classicandexotic.com/store/p-46-klaxon-k-22-k-19-horn-spring-mount.aspx Regards, Dave

Posted on: 2010/12/29 8:43

|

|||

|

||||

|

Re: Adjusting 32's horns

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

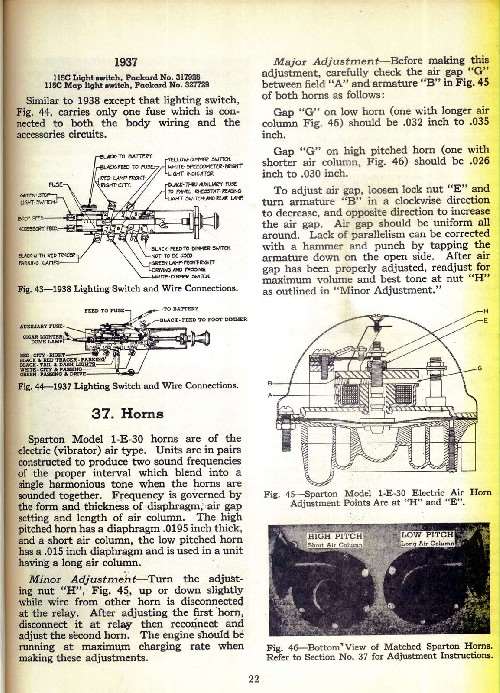

You might try reading up on horn adjustment in a later Packard shop manual. For example, the 1937/38 shop manual gives a procedure for Sparton horn adjustment with a nice, clear diagram. The horn they show is similar to that used in 33/34 and the general principles of adjustment should apply to yours.

Posted on: 2010/12/29 9:02

|

|||

|

||||

|

Re: Adjusting 32's horns

|

||||

|---|---|---|---|---|

|

Home away from home

|

New external horn brackets for '32's.

cgi.ebay.com/ebaymotors/1932-Packard-Hor ... rts_Accessories&hash=item2c59ad30dd Attach file:  (7.72 KB) (7.72 KB)

Posted on: 2010/12/29 9:25

|

|||

|

||||

|

Re: Adjusting 32's horns

|

||||

|---|---|---|---|---|

|

Home away from home

|

Here's some of what I was trying to say previously, showing where to look.

Thanks to Owen for the drawing.

Posted on: 2010/12/29 13:11

|

|||

|

||||

|

Re: Adjusting 32's horns

|

||||

|---|---|---|---|---|

|

Home away from home

|

Already bought these. When I first got my 32 five years ago, on of the brackets had already cracked. Then I found these which I am forever grateful that someone had repo'd them.

Posted on: 2010/12/29 13:11

|

|||

|

||||

|

Re: Adjusting 32's horns

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks guys. That's my next project after I replace the kitchen faucet.

Posted on: 2010/12/29 13:18

|

|||

|

||||

|

Re: Adjusting 32's horns

|

||||

|---|---|---|---|---|

|

Home away from home

|

Ok one horn barely works at all so my atention is on that one.

I'm trying to do the major adjustment first, but I'm confused. I unloosen the lock nut, but can't get anything turn. It says to turn the armature which I assume is the center piece with threads on it, but it won't turn. There is a large rectangular piece on top of the iron core. However you can't turn it unless you take the horn apart. Any advice?

Posted on: 2010/12/30 17:54

|

|||

|

||||

|

Re: Adjusting 32's horns

|

||||

|---|---|---|---|---|

|

Home away from home

|

I did some more work on the one horn and took it apart and cleaned up some corrosion. At one point it seemed to work until I tightened the lock nut for the points.

I'm using an adjustable 3A power supply. The good horn draws 1.5A. The bad horn is maxing out the 3A current from the supply.

Posted on: 2010/12/31 0:40

|

|||

|

||||

|

Re: Adjusting 32's horns

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Any indication the coil is burned or partially shorted. That would cause an increased current draw and poor operation. If there is corrosion in the armature/diaphragm area and it can't vibrate properly that could also pull more current. When tightening the locknut is anything drawn into any kind of insulation material.

Posted on: 2010/12/31 0:51

|

|||

|

Howard

|

||||

|

||||