|

Re: 32 rear brake drum removal

|

||||

|---|---|---|---|---|

|

Webmaster

|

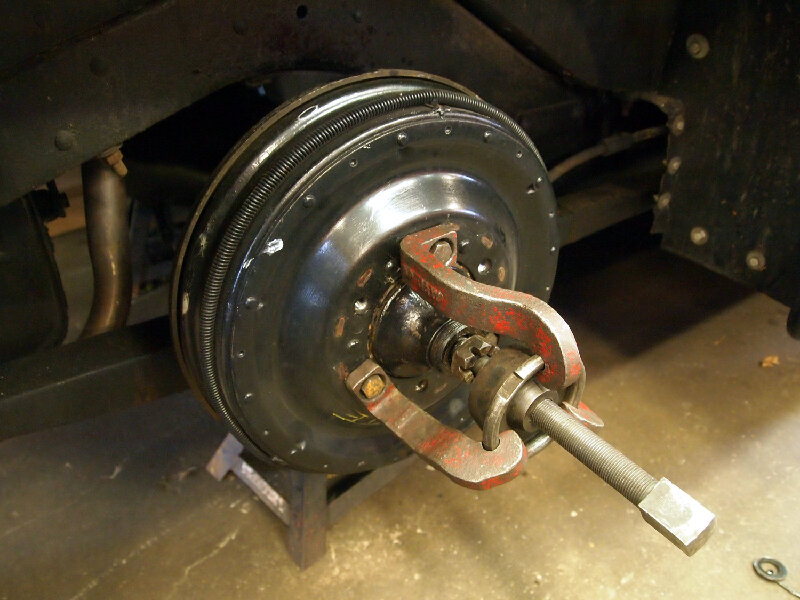

The key is there to keep the drum migrating on the tapered axle.

The drums are pressed on with about 200-250 ft. of force. Add rust, and it takes even more to break them loose. This is the recommended style of puller. The ability to tighten with the puller by hitting the dog bone wings on the end not only tightens it, but also that hammer shock helps break the mechanical/rust bond between the drum and the axle tapper.

Posted on: 2024/7/2 9:07

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

|

Re: 32 rear brake drum removal

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Illustrations from drum removal on my '34 Eight. Very typical of the construction used by Packard tru 1955, also used by Chrysler and many others. Any well-made puller of the types shown should do the job. Note that the axle nut is left on the shaft, loosely threaded, to safely retain the drum in place when it breaks free of the taper.

I suggest that your chances of removing it with the gear puller as you've illustrated are slim to none. Attach file:  Rear Wheel bearings 005.jpg (975.49 KB) Rear Wheel bearings 005.jpg (975.49 KB)  Rear Wheel bearings 001 sm.jpg (460.10 KB) Rear Wheel bearings 001 sm.jpg (460.10 KB)  Herbrand 825 hub puller_0061.jpg (526.15 KB) Herbrand 825 hub puller_0061.jpg (526.15 KB)

Posted on: 2024/7/2 11:01

|

|||

|

||||

|

Re: 32 rear brake drum removal

|

||||

|---|---|---|---|---|

|

Home away from home

|

This method was the same through at least 1955.

I suggest you just buy one of these. Your original picture will have the puller fly across the shop before that hub breaks loose. amazon.com/dp/B012P0QV5K

Posted on: 2024/7/2 11:21

|

|||

|

1955 400 | Registry | Project Blog

1955 Clipper Deluxe | Registry | Project Blog 1955 Clipper Super Panama | Registry Email (Parts/service inquiries only, please. Post all questions on the forum.) service@ultramatic.info |

||||

|

||||

|

Re: 32 rear brake drum removal

|

||||

|---|---|---|---|---|

|

Home away from home

|

You don't want to take a chance on damaging the drum. When I fist got my 1939 12, the drums had not been off in many years. An old timer at the time told me to loosen just a bit the nut put back in the cotter pin and drive it around the block a few times. That did it. Otherwise put pressure from your wheel puller and give it over night, and sometime during the night should pop off. Make sure you leave the nut partially on the axle so it does not fall on ground.

Posted on: 2024/7/2 13:58

|

|||

|

||||

28DF065D-B873-4EC3-8640-77D3C0AF4D7D.jpeg (382.57 KB)

28DF065D-B873-4EC3-8640-77D3C0AF4D7D.jpeg (382.57 KB)