|

Re: Flexible Fuel Lines and Fittings

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Not sure about the pump fittings other than maybe a 1/8 pipe 90 or 45 degree elbow for convenience depending on input side but there were at least two flex lines postwar for sure.

The 21st and possibly 22nd has the steel fuel line ending in a brass block bolted to the crossmember. The steel tube is brazed into the fitting which has a regular SAE male flare out. The flex line has 1/8 pipe straight into the pump and for the other end, a regular flare nut free to turn for tightening onto the brass fitting's flare. I believe 23rd started the tube itself ending in the inverted flare with the nut free to turn on the tube. Tube was just clipped to crossmember. That hose has a female flare end for the tube nut to turn into and a regular 1/8 pipe end for the pump. Believe that stayed unchanged thru 56.

Posted on: 2013/9/19 12:29

|

|||

|

Howard

|

||||

|

||||

|

Re: Flexible Fuel Lines and Fittings

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

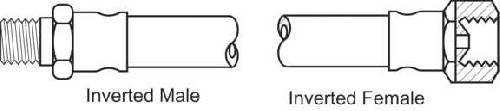

That's good information HH and I appreciate your providing it. It's sometimes difficult to go back and correct some modifications that other people don't consider to be important but engineers usually design things a specific way for a reason and I prefer to keep them that way when and where possible. What threw me was that the two AC fuel pump cores that I recently purchased had inverted flare 90 degree fittings for the hose to connect to the pump and in researching the subject, NAPA even showed their replacement hose with a a female inverted flare on the tube end and a male inverted flare on the pump end but like I said, the two fittings are close enough in appearance to easily confuse since the threads are the same. I just ordered a new flex hose from Then and Now and will wait to see what fitting they used for the pump end of the hose. if its 1/8" NPT then I'll connect it to the pump with a 90 degree NPT. Thanks Again.

Posted on: 2013/9/19 15:15

|

|||

|

||||

|

Re: Flexible Fuel Lines and Fittings

|

||||

|---|---|---|---|---|

|

Home away from home

|

When I crossed this problem, I got the correct pump number off the parts list. I got the rebuild kit for that pump from Then and now and it came with a copy of the original parts diagram. My pump didn't match completely as it was a reman.

The engine plates showed the correct line runs/connections. So you can check the pump numbers and get the original diagrams from Then and Now and compare to what you have to see what's correct or not. You can check with a concourse judge also. Or you can do like the previous owner and just make it run. Just use fuel rated tube fittings on the pressure side and fuel rated hose on the inlet and route where it don't get hung, allows some movement, you can access, and looks good. You can look up the SAE specs. Typically, hose connections will be NPT. Tube can be several types, compression, flare, and Iflare. Iflare is mostly in brake systems, but they used it in this period on fuel, as 5/16" was plenty for those motors. It's not typical to find a fuel housing with a direct Iflare connection. My outlet had a NPT to Female Iflare brass connector which are not easy to find, but Grainger etc. carries. The inlet(low pressure side) is typically hose. Class it up and use a fitting not slip the hose on the flared tube end which is often the case. It'll work.

Posted on: 2013/9/19 16:34

|

|||

|

||||

(8.73 KB)

(8.73 KB)